Polishing device for building wall

A technology for building walls and positioning columns, which is applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems of inflexible and convenient adjustment, poor grinding effect, and low grinding efficiency, and achieve the best grinding process. Stable and efficient, improve wall grinding efficiency, and strong adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

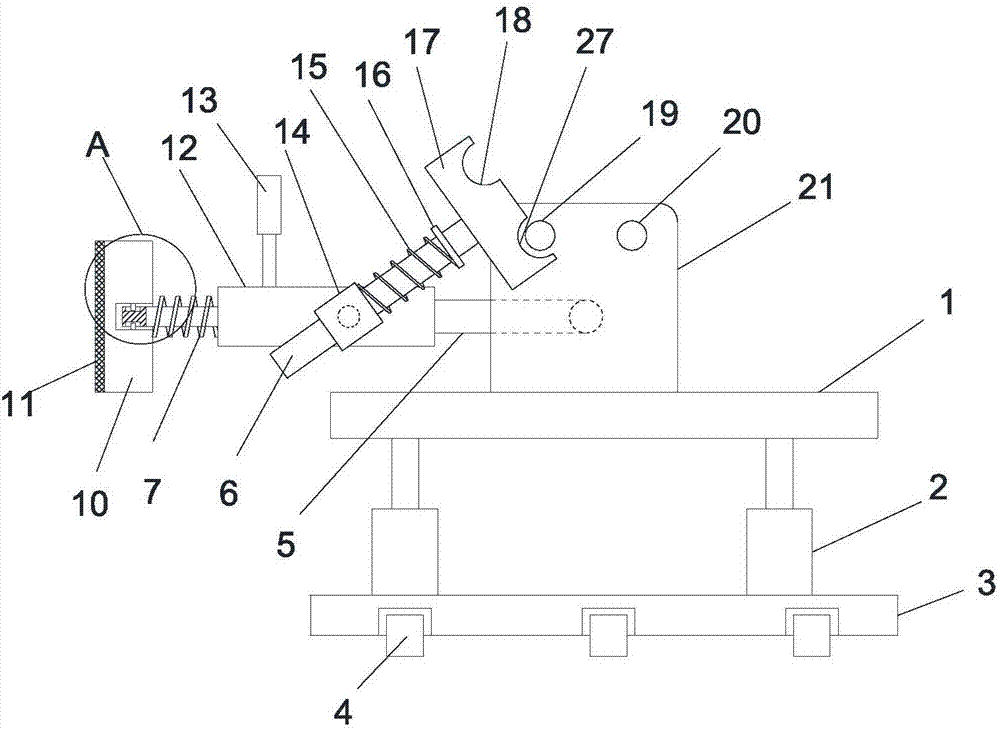

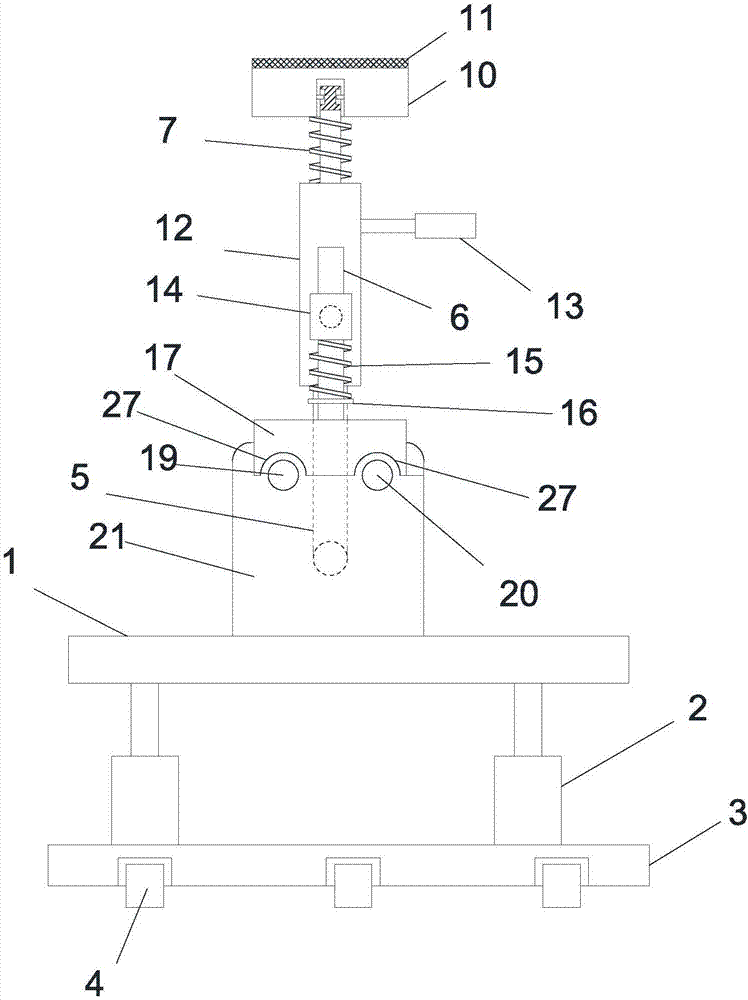

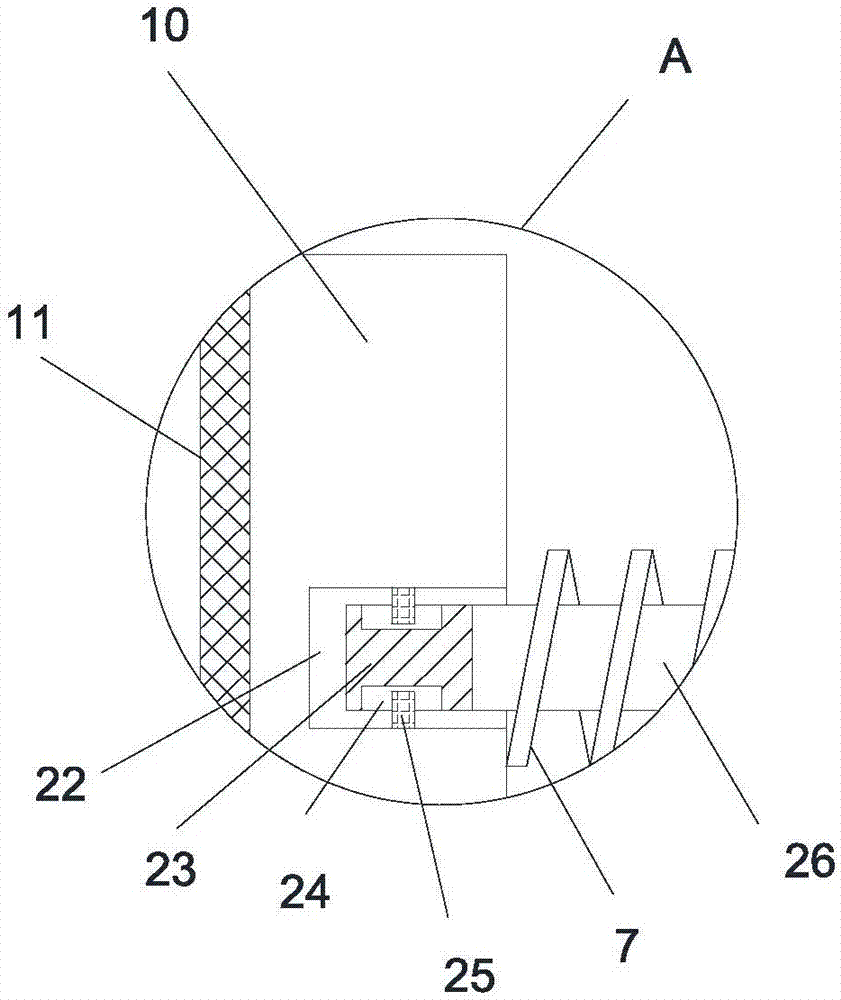

[0020] see Figure 1-4 , a building wall grinding device, comprising a base plate 3, the bottom of the base plate 3 is rotatably provided with several walking wheels 4, and the upper side of the base plate 3 is vertically fixed with several telescopic rods 2, and the telescopic rod 2 is horizontally provided with Support plate 1, the upper surface of the support plate 1 is vertically fixed with a vertical plate 21, the vertical plate 21 is a rectangular plate-mounted structure, and the vertical plate 21 is symmetrically fixed with a first cylindrical column with respect to the vertical center line of the vertical plate 21. Positioning column 19 and second positioning column 20, described first positioning column 19 is positioned at the left side of second positioning column 20, and first positioning column 19 and second positioning column 20 are verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com