Marble making system

A manufacturing system, marble technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of poor quality, troublesome transfer processing, low degree of automation, etc., achieve standardization of glue bonding quality, and improve production efficiency , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following embodiments may enable those skilled in the art to fully understand the present invention, but they do not limit the present invention to the scope of the described embodiments.

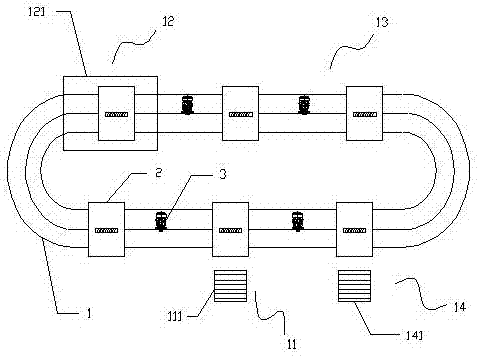

[0020] Such as figure 1 The marble manufacturing system shown includes a sliding guide rail 1, a pressing device 2 and a driving mechanism 3.

[0021] The sliding guide rail 1 is connected end to end in a ring structure, and the sliding guide rail 1 is sequentially demarcated with a glue area 11, a drying area 12, a cooling area 13 and a lower board area 14;

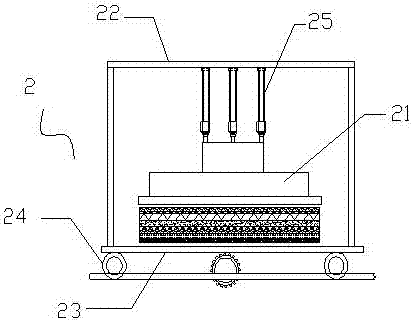

[0022] Such as figure 2 As shown, the pressing device 2 has a number of which are arranged in series on the sliding guide rail 1. The pressing device 2 is driven by the driving mechanism 3 to cyclically move along each area of the sliding guide rail 1. The driving mechanism 3 is set on the sliding guide rail 1. The motor and a fixed gear set below the pressing device 2; adjacent pressing devices 2 are driven in series by a cha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap