Diesel locomotive oil composition and application thereof

An oil composition, a technology for diesel locomotives, applied in the directions of lubricating compositions, petroleum industry, additives, etc., can solve the problems of high temperature detergency, insufficient dispersibility of oil sludge, etc., achieve inhibition of the formation of oxidation products, good technical effects, and improved dispersion. performance effect

Inactive Publication Date: 2017-11-10

CHINA PETROLEUM & CHEM CORP

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] One of the technical problems to be solved by the present invention is that the railway diesel locomotive oil composition in the prior art is used in the railway diesel locomotive system, and there are problems of insufficient high temperature detergency and sludge dispersibility. A new railway diesel locomotive oil is provided combination

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

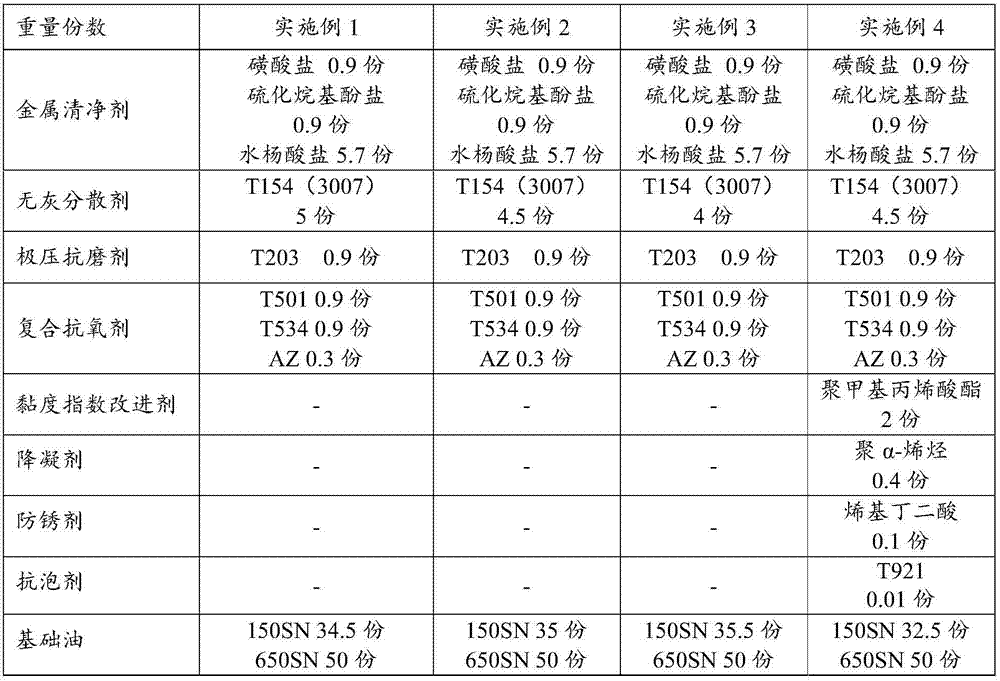

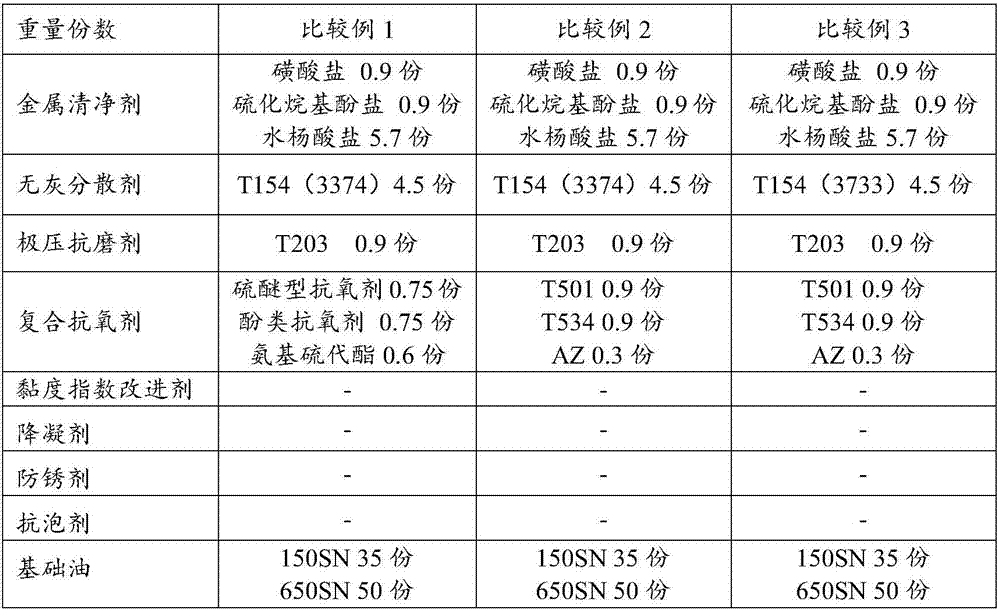

Embodiment 1~4

[0032] Add each component into the base oil in proportion at 65° C., stir for 0.5 to 5 hours to dissolve them all, and obtain the diesel locomotive oil composition of the present invention. The numbers in parentheses are the molecular weights of the ashless dispersants used. See Table 1 for details.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a diesel locomotive oil composition and application thereof, and mainly solves the problems of insufficient high temperature detergency and the sludge dispersibility when the railway diesel locomotive oil composition is used in a railway internal combustion engine system in the prior art. The diesel locomotive oil composition solves the problem well by adopting the technical scheme, the oil composition is prepared from, by weight, a, 3-10 parts of metal detergent, wherein the metal detergent is composed of 0.5-3.5 parts of sulfonate, 0.5-3.5 parts of vulcanized alkylphenol and 2-9 parts of salicylate; b, 3-7 parts of low molecular weight polyisobutene succinimide ashless powder, the molecular weight range is 3000-3200; c, 0.5-3 parts of phosphorus-containing anti-wear preservative; d, 0.5-3 parts of complex antioxidant; e, 80-95 parts of base oil. The technical scheme can be used in the industrial production of railway internal combustion locomotive oil composition.

Description

technical field [0001] The invention relates to a diesel locomotive oil composition and its application. Background technique [0002] Railway diesel locomotive oil is mainly used in the internal combustion engine system of railway locomotives. The working conditions of railway internal combustion engine oil are very harsh. The oil will generate sludge, paint film, carbon deposit and other oxidized substances during use, which will lead to problems such as oil circuit blockage and piston ring wear. Improving the cleaning and dispersing ability of oil products can better disperse some precursors of sludge, varnish, and carbon deposits in oil products, thereby effectively inhibiting the formation of various oxidation products. [0003] The document CN200310104206 discloses a lubricating oil for a railway locomotive internal combustion engine, which has a good anti-wear and extreme pressure function. [0004] Document CN02131228 discloses a modified engine oil that can be use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04C10M149/02C10N40/25C10N30/04

CPCC10M149/02C10M169/044C10M2205/02C10M2207/026C10M2207/12C10M2207/144C10M2209/08C10M2215/064C10M2217/06C10M2219/02C10M2219/044C10M2219/068C10M2223/045C10N2010/04C10N2030/04C10N2040/25

Inventor 魏真高娟

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com