Cloth material folding, sewing and ironing device

An ironing device and fabric folding technology, applied in sewing equipment, sewing machine components, cloth feeding mechanism, etc., can solve problems such as low degree of automation, easy creases in cloth, difficulty in maintaining consistent product appearance and quality, and avoid mutual interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

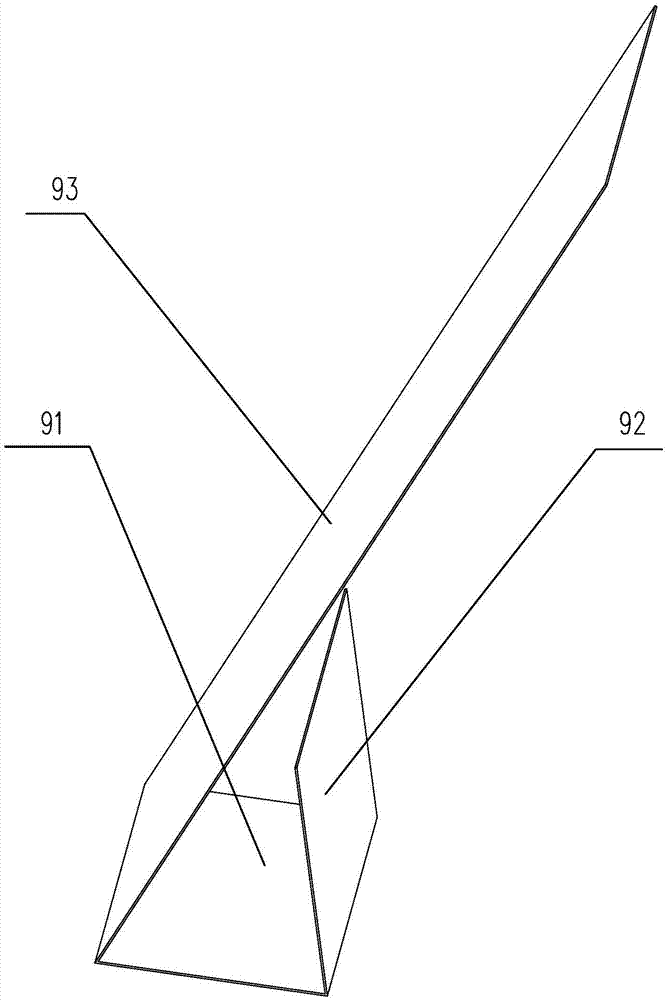

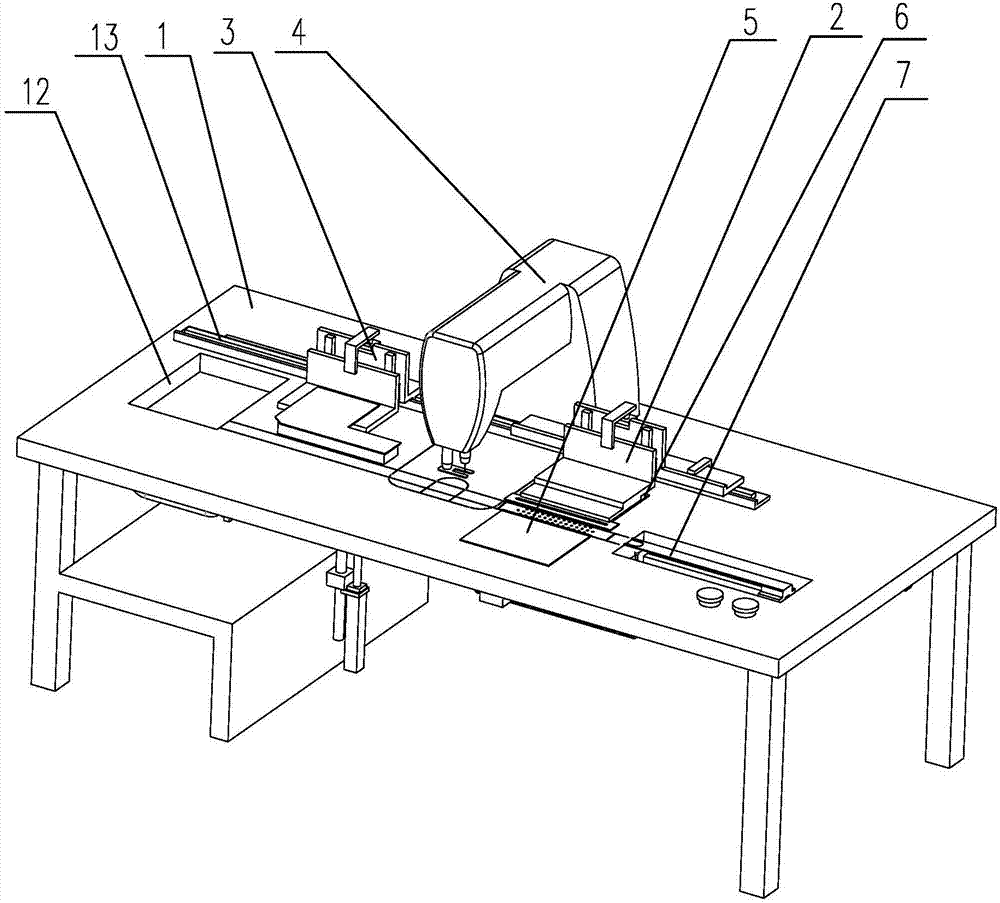

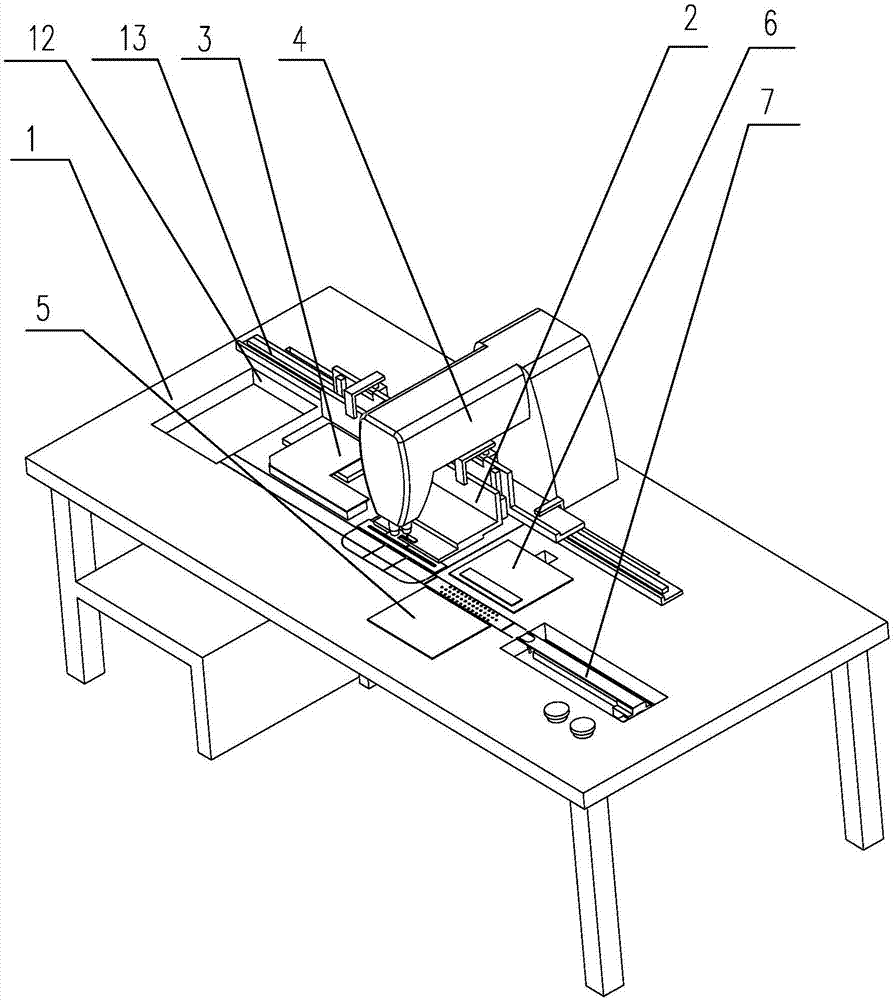

[0033] Depend on Figure 1 to Figure 2 It can be seen that the present invention discloses a cloth folding, sewing and ironing device, which includes a support 1, a sewing machine 4 and an ironing mechanism 3. The support 1 is provided with a storage place 11 for placing the cloth to be processed. The support 1 A suction port 17 for absorbing the cloth on the support 1 is provided at the corresponding position of the storage place 11, and the support 1 is provided with a positioning mechanism 7 for pressing the cloth pressing portion 91 against the storage place 11 on the side of the storage place 11 The positioning mechanism 7 includes a first mounting base 72, an elastic pressing plate 71, a push rod 73, and a first driving member 74 for driving the push rod 73 to lift the elastic pressing plate 71 when the elastic pressing plate 71 is stretched out. A track is provided longitudinally on the bracket 1, and the first mounting seat 72 is slidably arranged on the track and is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com