Standardized unit fabricated composite wall

A composite wall, prefabricated technology, applied in building components, buildings, building structures, etc., can solve the problems of not satisfying the aesthetic appearance of civil buildings, thermal insulation and sound insulation performance, etc., to ensure wind pressure resistance and a broad market. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

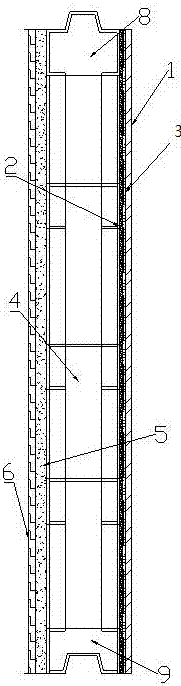

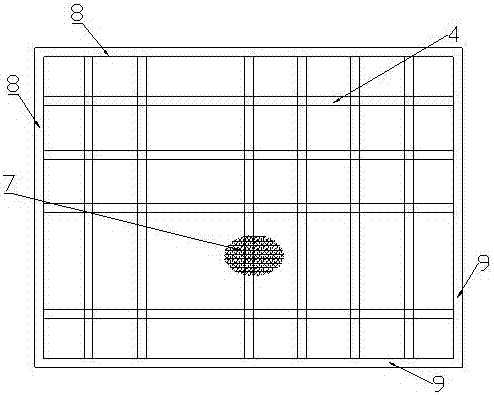

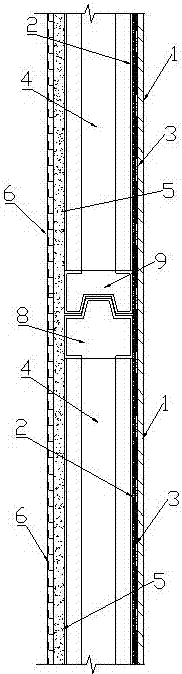

[0020] See Figure 1-7 , A standardized unit assembled composite wall, comprising an outer wall, a skeleton 4 and an inner wall, the outer wall including an outer wall finishing layer 1, an outer wall reflective insulation film 2 and a unidirectional breathable moisture-proof layer 3 The inner wall includes the inner wall sound-absorbing layer 5 and the inner wall finishing layer 6. The outer wall finishing layer 1 is made of PVDF profiled steel plate, the inner wall sound-absorbing layer 5 is made of sound-absorbing materials, and the skeleton 4 is filled with rock wool 7 , The frame lap part of the frame 4 adopts the first tongue-and-groove purlin 8 and the second tongue-and-groove purlin 9 and the first tongue-and-groove purlin 8 and the second tongue-and-eye purlin 9 of the different frame 4 are used together, and the interior wall decoration The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com