Whole type high-pressure anti-explosion seal-seal maintaining-free revolving compensator and manufacturing method thereof

A rotary compensator and self-sealing technology, which is applied in expansion compensating devices for pipelines, adjustable connections, passing components, etc., can solve problems such as increasing rotation resistance, affecting economic benefits, and sealing failure, so as to improve the ability to resist torsion , enhance the explosion-proof function, and ensure the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

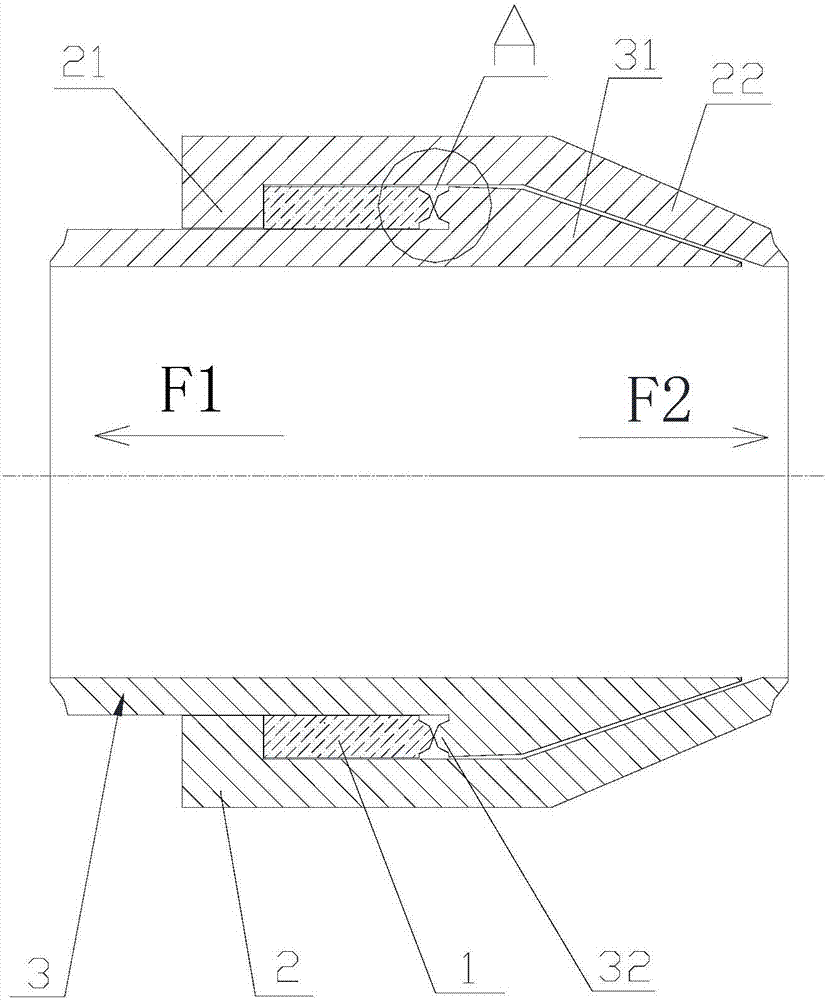

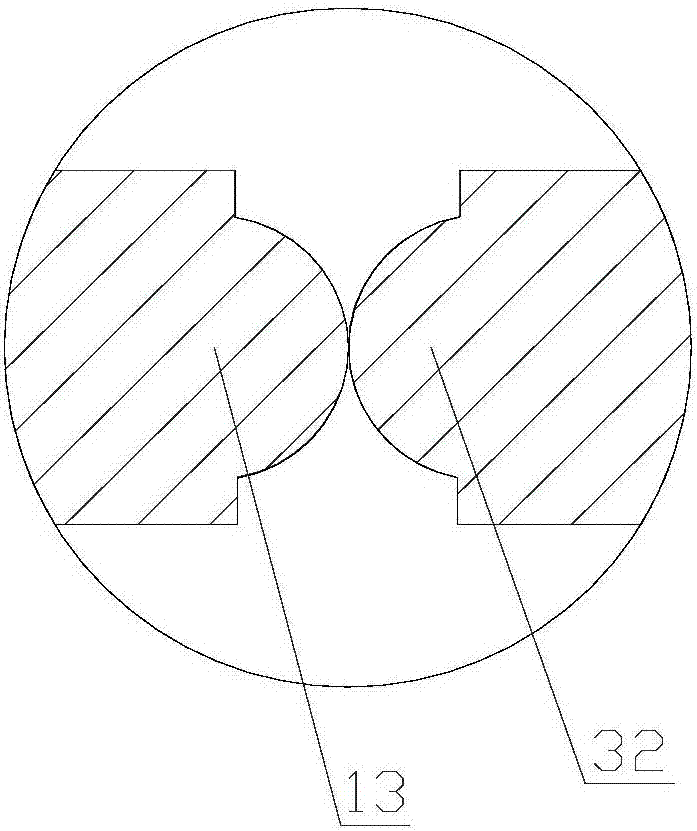

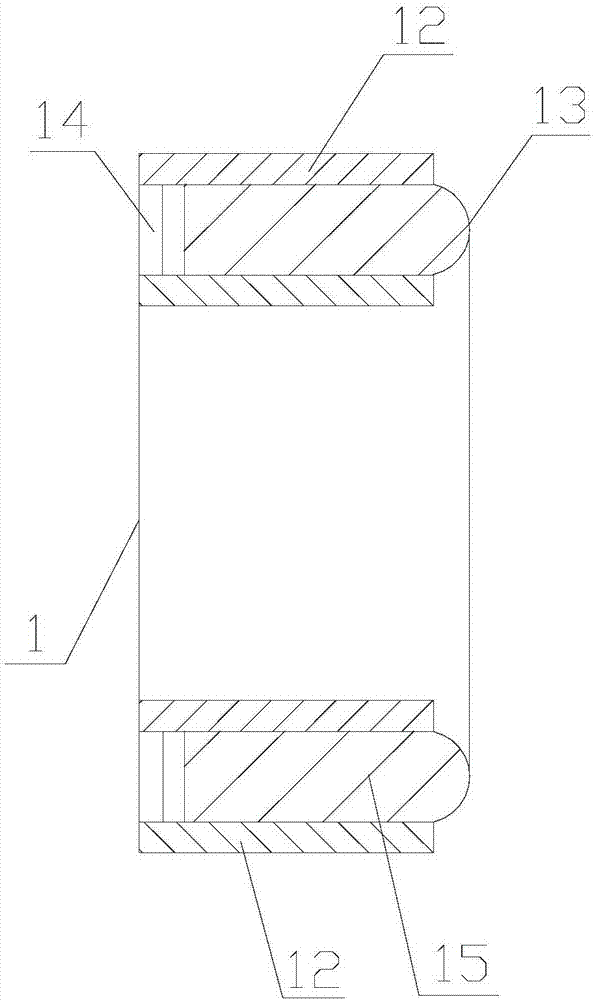

[0026] Such as figure 1 , figure 2 with image 3 As shown, the integral high-pressure explosion-proof self-sealing maintenance-free rotary compensator includes a rotating tube 3 and an outer casing 2. The rotating tube 3 is set inside the outer casing 2. The other end is provided with a tapered shrink tube 22, and the tapered shrink tube 22 and the outer sleeve are set as an integral structure. The end of the rotary tube 3 near the outer tube 2 tapered shrink tube 22 is provided with a conical annular boss 31, the side of the annular boss 31 is provided with a spherical convex ring 32, the annular boss 31 of the rotary tube and the limit of the outer tube A packing sealing chamber is provided between the rings 21, and a sealing packing is provided in the sealing chamber.

[0027] In this embodiment, the sealing packing in the sealing cavity is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com