Radial Flow Combustor Diffuser and Gas Turbine

A gas turbine and combustion chamber technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of inconsistent airflow speeds in the passages around the flame tube, and achieve the effects of easy processing, reduced total pressure loss, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

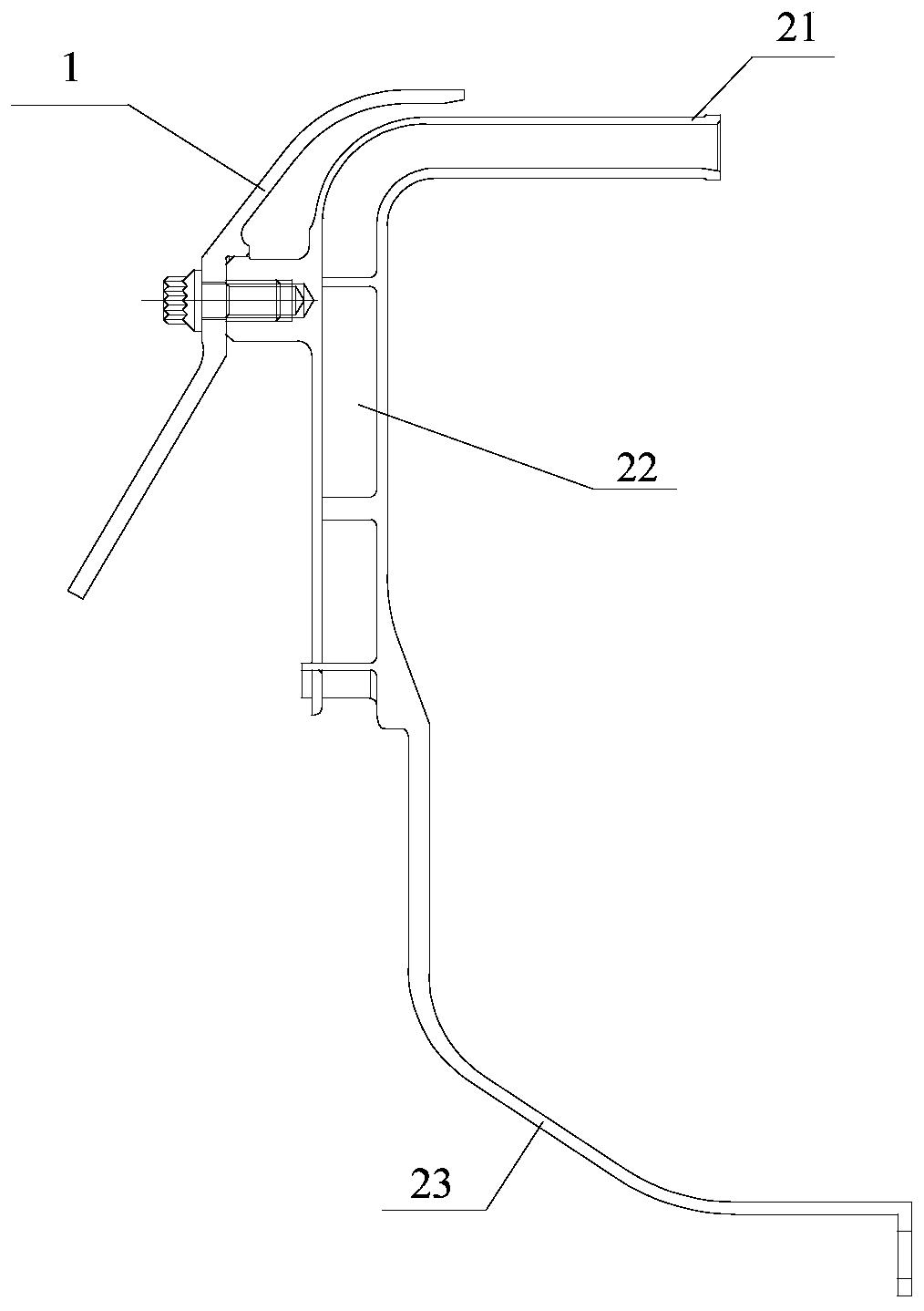

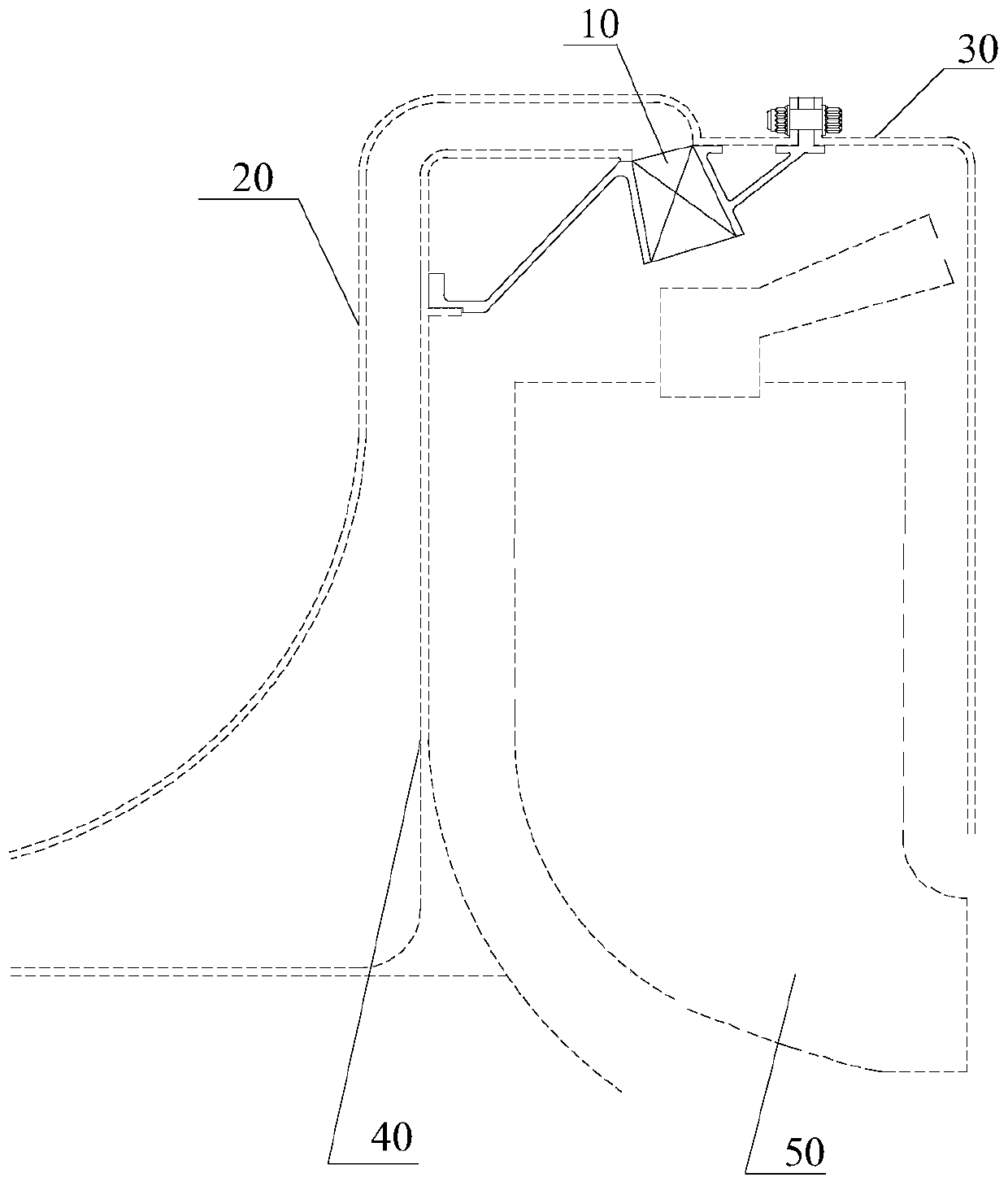

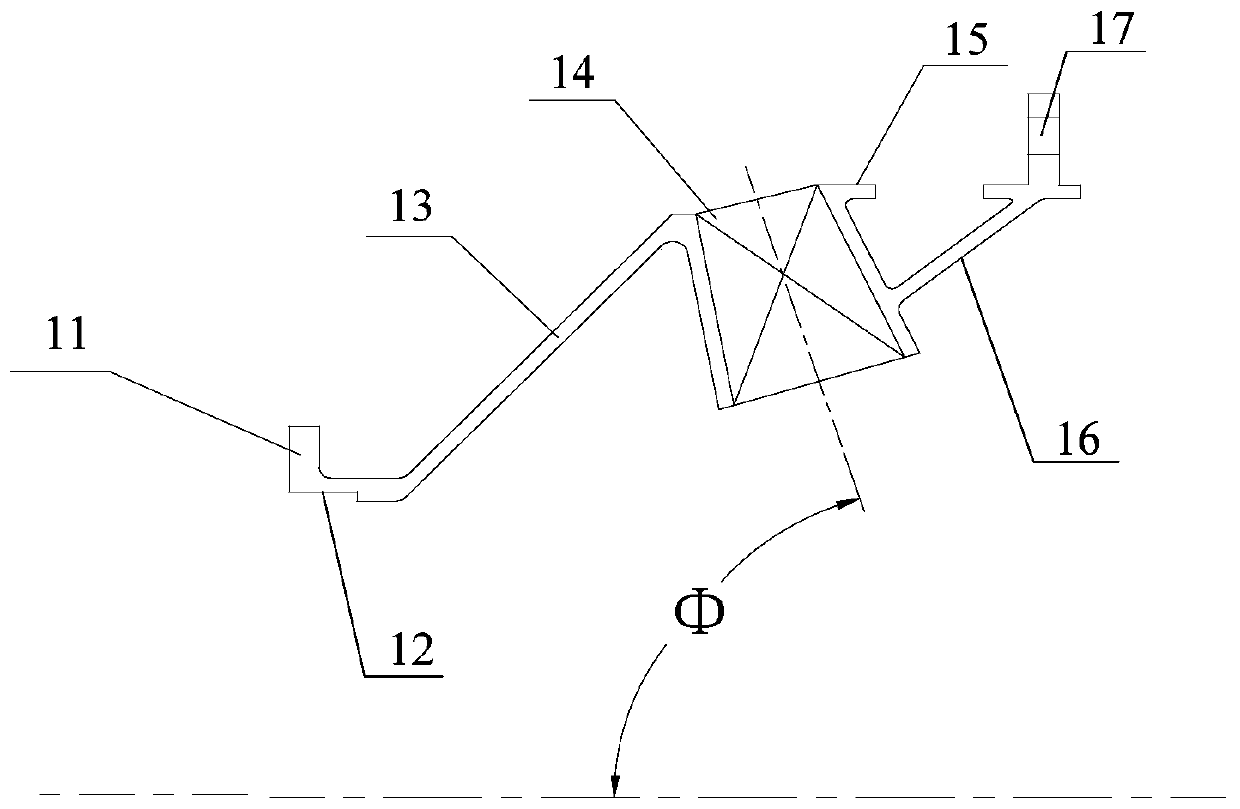

[0028] refer to Figure 2 to Figure 3 , the preferred embodiment of the present invention provides a diffuser for a radial flow combustor, because most of the existing diffusers are adapted to a direct-flow combustor or a recirculation combustor, and the exhaust gas of this diffuser The method is axial exhaust, but the radial airflow cannot be diffused and decelerated. Using the existing diffuser will cause inconsistent airflow speeds around the flame tube entering the combustion chamber, resulting in insufficient combustion, so that the combustion chamber is ineffective. Pressure loss increases. And the present invention is adapted to the diffuser of the radial flow combustion chamber, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com