Fluidized bed and method for preparing catalyst by using fluidized bed

A fluidized bed and catalyst technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of uneven loading of catalyst active components, uneven impregnation, etc., and achieve uniform impregnation, The effect of uniform product and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

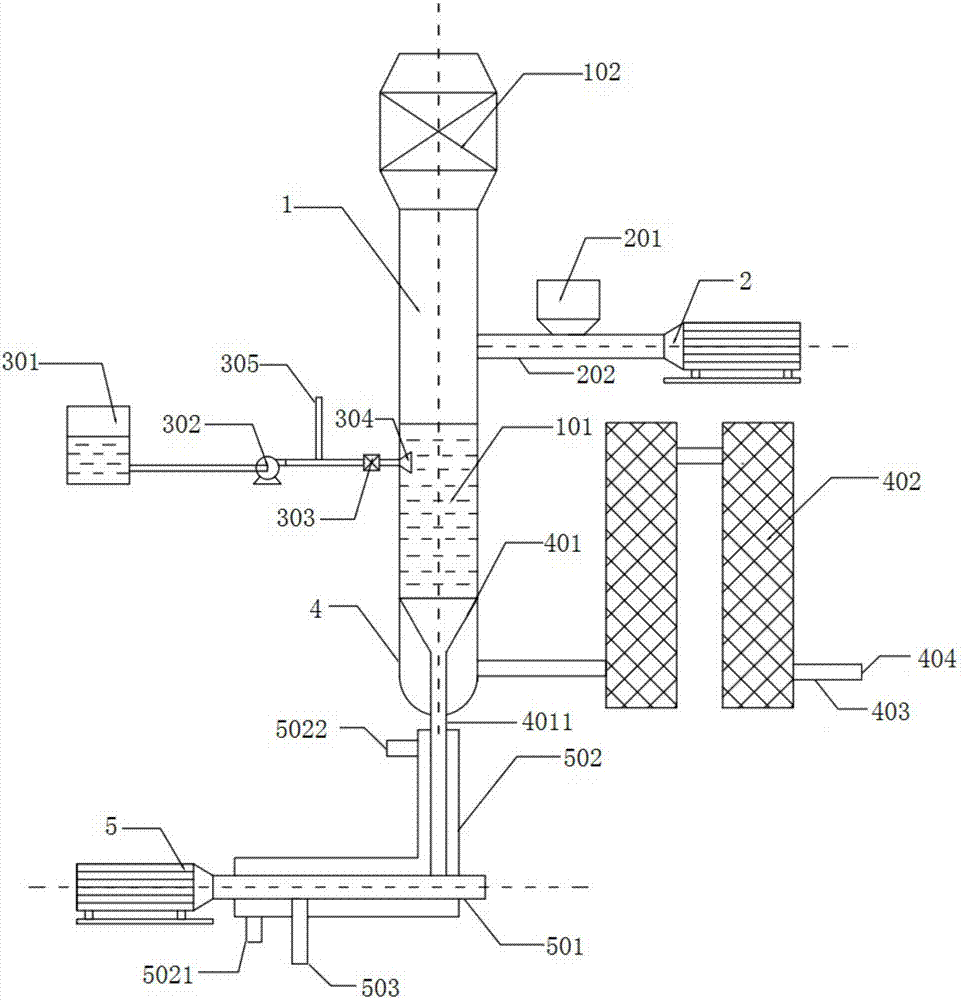

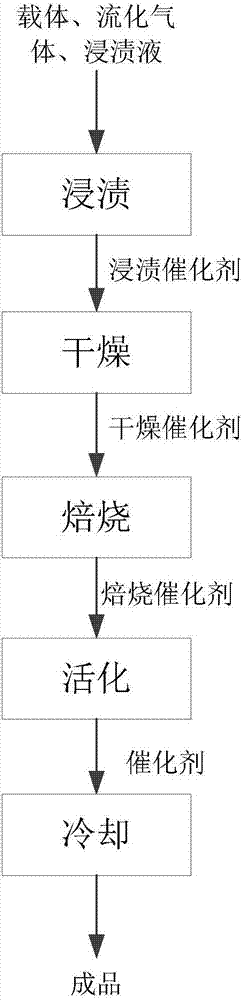

[0073] use figure 1 The fluidized bed shown and figure 2 The process flow shown for the preparation of Pt / Al 2 o 3 reforming catalyst. In this embodiment, the cross-sectional area of the enlarged section 102 is three times the cross-sectional area of the fluidized section 101, the gas hole diameter of the gas distributor 401 is 3mm, and the center-to-center distance between two adjacent gas holes is 3 mm of the tube of the gas distributor 401. 3 times the diameter, the gas distributor 401 is conical, and the cross-sectional area of the downcomer 4011 is 40% of the cross-sectional area of the fluidized section 101. The fluidizing gas is air and the reducing gas is CO.

[0074] High-purity γ-Al with a diameter of 3mm 2 o 3 The small ball is used as the carrier, and the chloroplatinic acid with a concentration of 2.45g / L is used as the impregnating solution. per kg γ-Al 2 o 3 Immerse in 0.6L of chloroplatinic acid solution.

[0075] The fluidized bed 1 is fed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com