A method for treating reverse osmosis concentrate by using secondary iron minerals to activate persulfate

A reverse osmosis concentrate, monosulfate technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of sulfate radical quenching, limited application, etc. Scale and corrosion, simple and easy operation, high decontamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

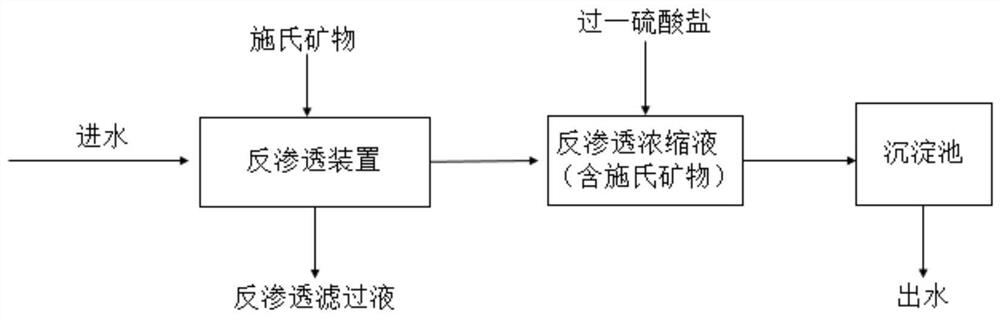

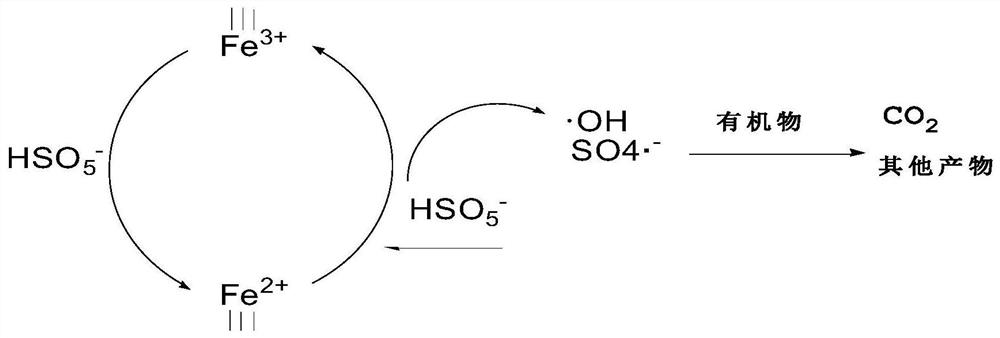

[0026] Specific embodiment one: a kind of method of utilizing secondary iron mineral activation peroxosulfate of the present embodiment to process reverse osmosis concentrated solution, it is realized by following steps:

[0027] 1. Add the crushed secondary iron minerals that pass through a 200-mesh sieve into the water to be treated by reverse osmosis, and perform reverse osmosis treatment;

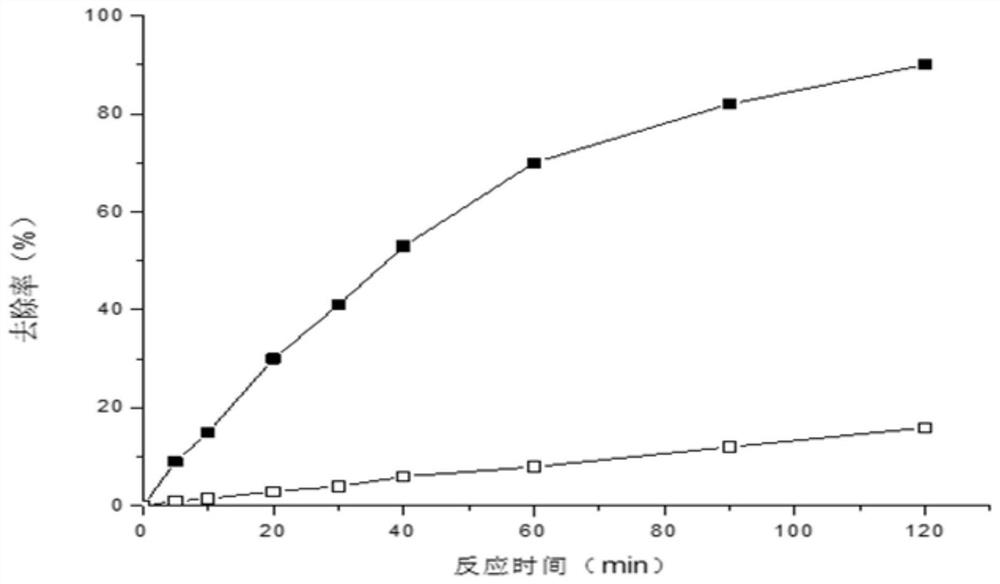

[0028] 2. Add peroxymonosulfate to the reverse osmosis concentrated solution after the reverse osmosis treatment in step one, stir, control the mass ratio of catalyst and peroxymonosulfate to be 1: (1~10), and control the concentration of peroxomonosulfate to be 100 ~5000mg / L, the hydraulic retention time is 30~180min, that is, the use of secondary iron minerals to activate persulfate to treat the reverse osmosis concentrate.

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the described permonosulfate is potassium peroxosulfate, sodium peroxosulfate, ammonium permonosulfate, calcium peroxosulfate, magnesium peroxosulfate One or more mixtures mixed in any proportion. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment is different from Embodiment 1 in that: the secondary iron mineral is Shi's mineral. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com