Knitted integrated shoe with knitted tapes and knitting technology of shoe

A webbing and integrated technology, which is applied to the weft knitting circular machine, knitting, weft knitting and other directions with single action needles, can solve the problem of the reduction of the firmness of the shoe body at the webbing, waste of leftover materials, and damage to the quality of the shoe body and other problems, to achieve the effect of reducing pasting and post-processing procedures, improving production efficiency, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

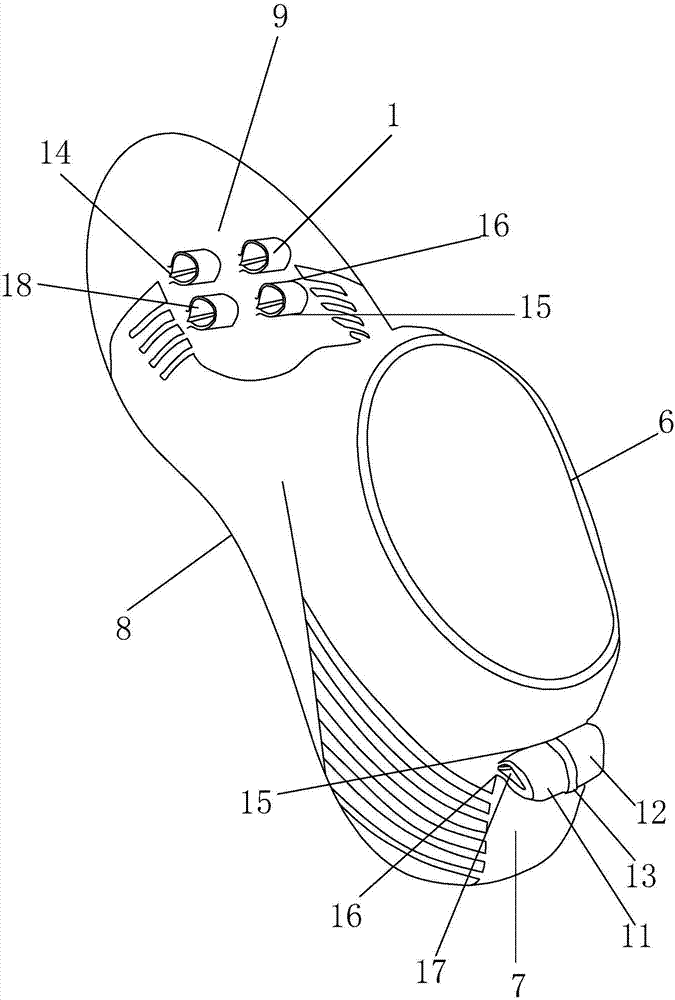

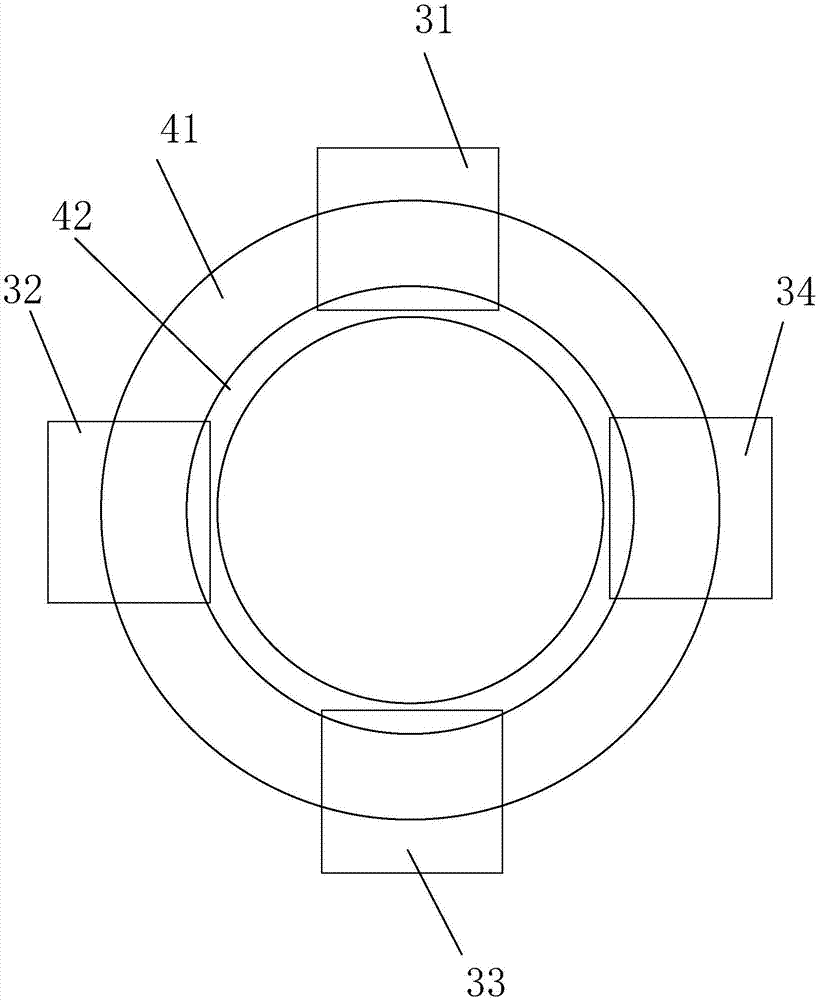

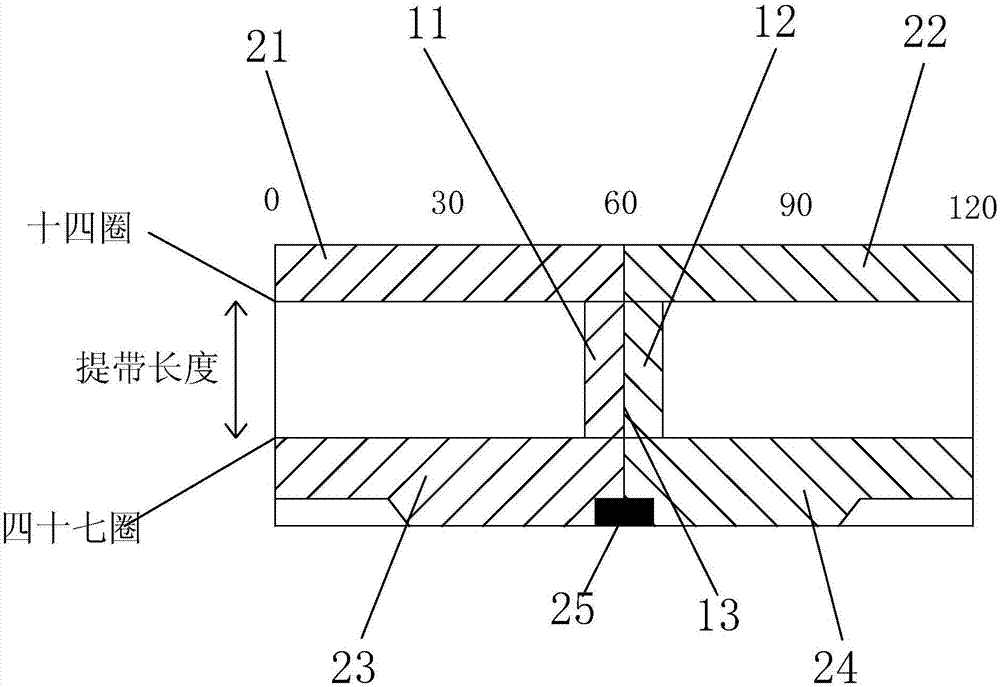

[0040] Such as Figure 1 to Figure 4 As shown, a knitted integrated shoe with a ribbon 1 is a sock shoe, which includes a shoe body integrally knitted by a sock machine. The shoe body is a cylinder with a unique opening. The shoe body includes a cuff portion 6 and a heel portion 7 , the vamp 9 and the sole 8 also include the webbing 1 integrally woven with the shoe body. Due to the integrated weaving, the combination of the webbing 1 and the shoe body is firm and reliable, and the shoe body is fixed on the selected shoe body after subsequent processing. After the sole is trimmed, a complete sock shoe can be formed, and the production process of the whole sock shoe becomes simpler. Put the shoe body on the last or the human foot, the shoe body corresponds to the toe and the heel respectively correspond to the front and back direction; the shoe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com