Powder material feeding device of alchlor generator

A powder material, aluminum trichloride technology, applied in the direction of aluminum chloride, feeding device, aluminum halide, etc., can solve the problems of large fluctuations in the amount of addition, unstable pressure of the feeding system, unstable state of aluminum powder, etc., to achieve The effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

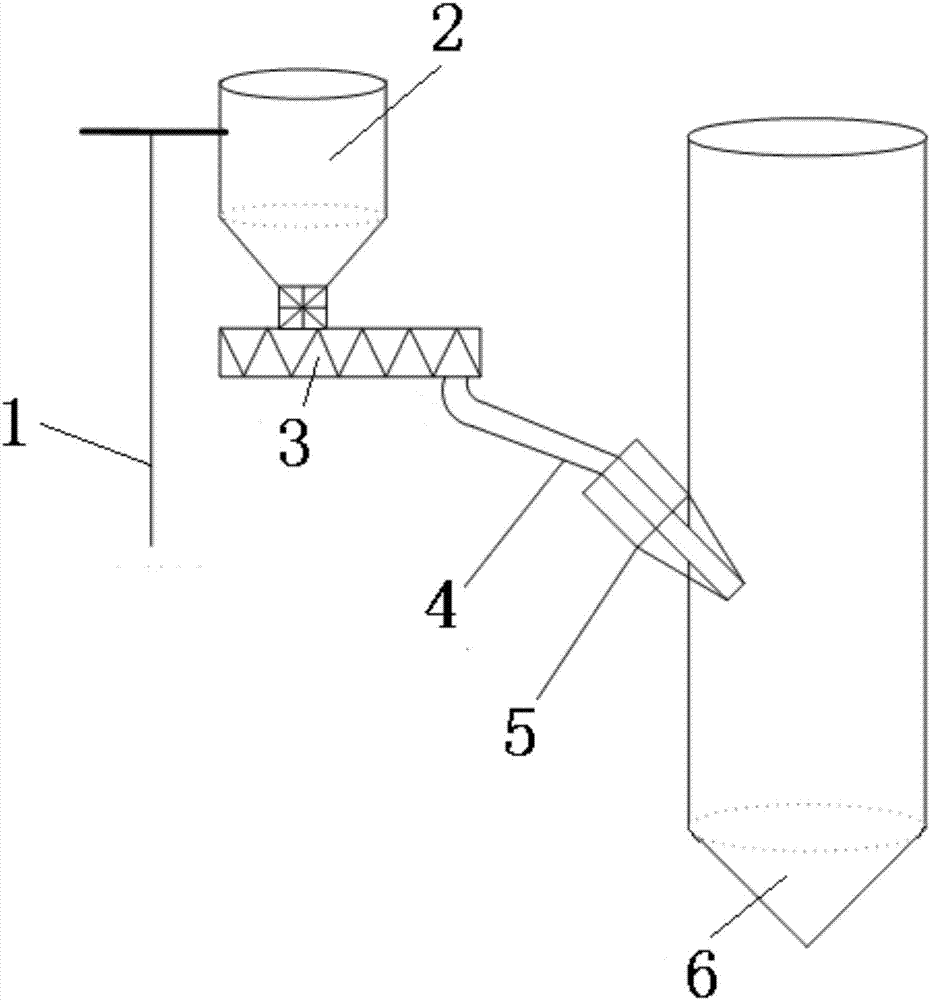

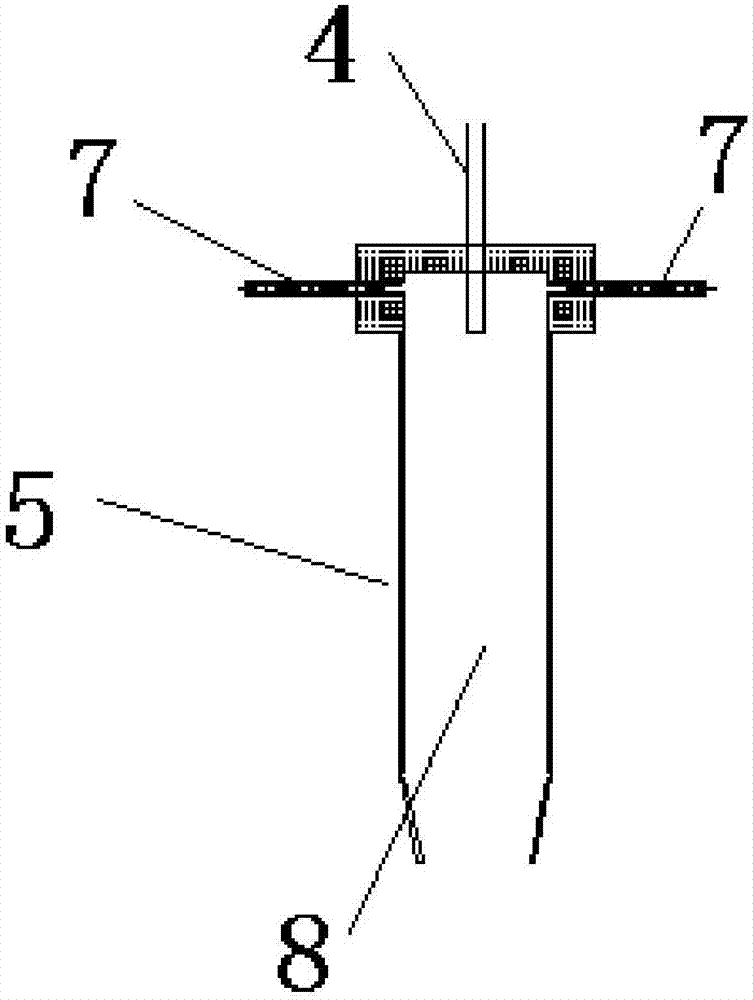

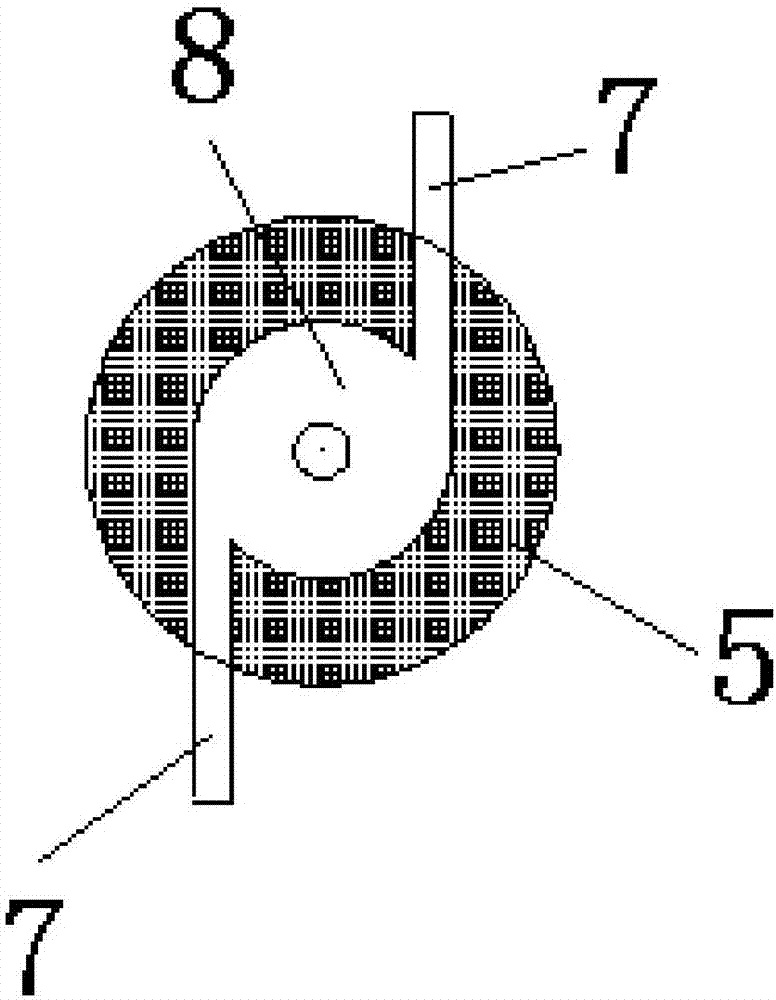

[0018] Such as figure 1 , figure 2 , image 3 The shown aluminum trichloride generator powder material feeding device comprises a feeding spray gun 5, and the charging spray gun 5 is provided with at least one chlorine gas pipe 7 inputting chlorine gas along the tangential direction of the side wall of the feeding spray gun 5, and the charging spray gun 5 is provided with a feeding pipeline 4, and the material is output through the nozzle 8 of the feeding spray gun 5.

[0019] In actual use, the powder material enters the feeding spray gun 5 through the feeding pipeline 4, and then under the action of the chlorine gas pipe 7 that inputs chlorine gas along the tangential direction of the side wall of the feeding spray gun 5, it is carried and mixed by the input chlorine gas, And finally enter the aluminum trichloride generator 6 for reaction. Since excess heat can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com