Adsorbing type reaction device for organic synthesis

A reaction equipment and organic synthesis technology, applied in the field of adsorption-type reaction equipment, can solve the problems of odor, strong odor, etc., and achieve the effect of controlling emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

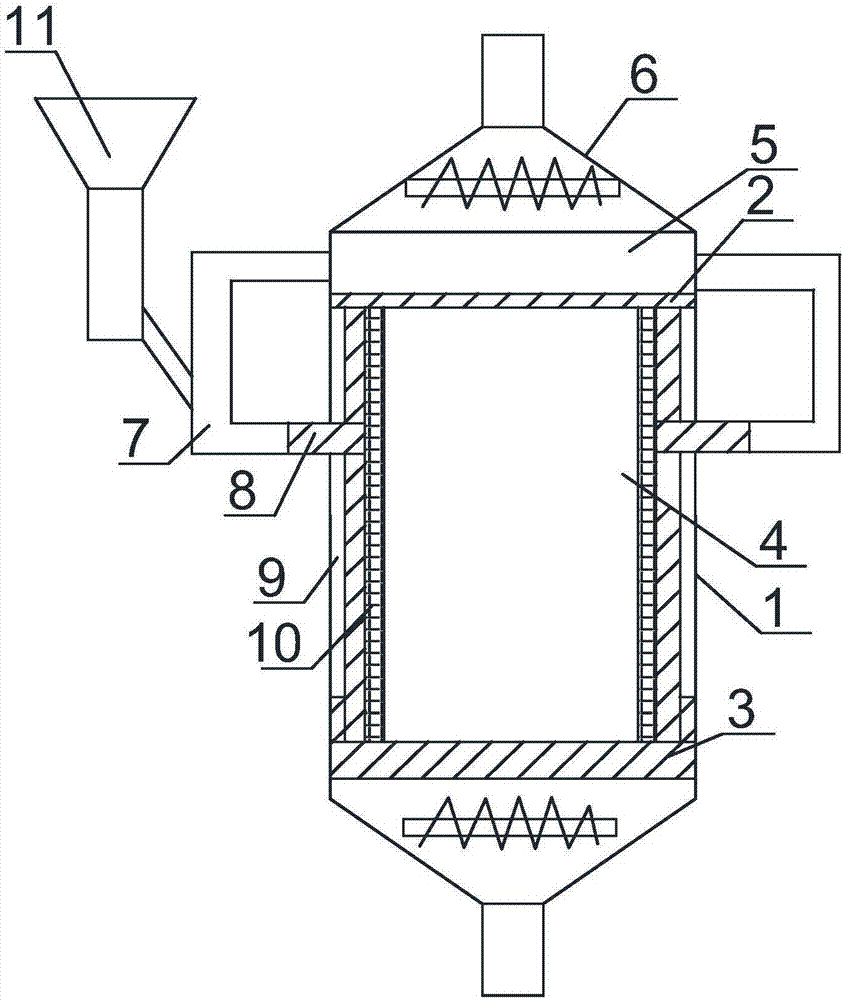

[0022] Such as figure 1 As shown, the present invention is used for the adsorption type reaction equipment of organic synthesis, comprises kettle body 1, and the upper bottom surface of described kettle body 1 is heat insulation board 2, and the lower bottom surface of kettle body 1 is heat conduction plate 3, and heat insulation board 2 and The heat conduction plate 3 seals the kettle body 1, and the cavity between the heat insulation plate 2 and the heat conduction plate 3 is a reaction chamber 4, and the top of the heat insulation plate 2 is connected with a box body 5 with a solid air freshener inside, and the box body 5 A first heating cover 6 with a heating device inside is connected above the top of the heat conduction plate 3, a second heating cover with a heating device inside is connected under the heat conduction plate 3, and a conduit 7 communicating with the inside of the box body 5 is connected to the side of the box body 5 , the conduit 7 is connected to the rea...

Embodiment 2

[0025] Based on embodiment 1, the inside of the chamber wall of the reaction chamber 4 is provided with a condensation chamber 9 with condensed water, the chamber wall of the reaction chamber 4 is an adiabatic chamber wall, and the condensation chamber 9 is located at the top of the reaction chamber 4 .

[0026] The condensation chamber is used to condense the gas at the top of the reaction chamber, which is conducive to the recovery of reactants such as volatilized organic solvents, improves the conversion rate of organic synthesis, and can also reduce the emission of organic matter.

Embodiment 3

[0028] Based on the above embodiment, the port of the conduit 7 inside the reaction chamber 4 is provided with a grid-like baffle 10 on the side close to the inside of the reaction chamber 4 , and the grid-shaped baffle 10 completely covers the port surface of the conduit 7 .

[0029] The grid-shaped baffle can not only play the role of filtration, but also play the role of condensing and guiding liquid. After the steam generated in the reaction chamber hits the grid-shaped baffle, part of the steam will condense into liquid and return to the reaction chamber. Continue to react.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com