Welding paste smearing device of pre-welding procedure of exhaust pipe of upper shell of air conditioner compressor

A technology for air-conditioning compressors and exhaust pipes, which is applied to tin feeding devices, welding equipment, manufacturing tools, etc. It can solve the problems of cumbersome smearing procedures, low efficiency, and inability to achieve uniform smearing, and achieves solutions to uneven smearing, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

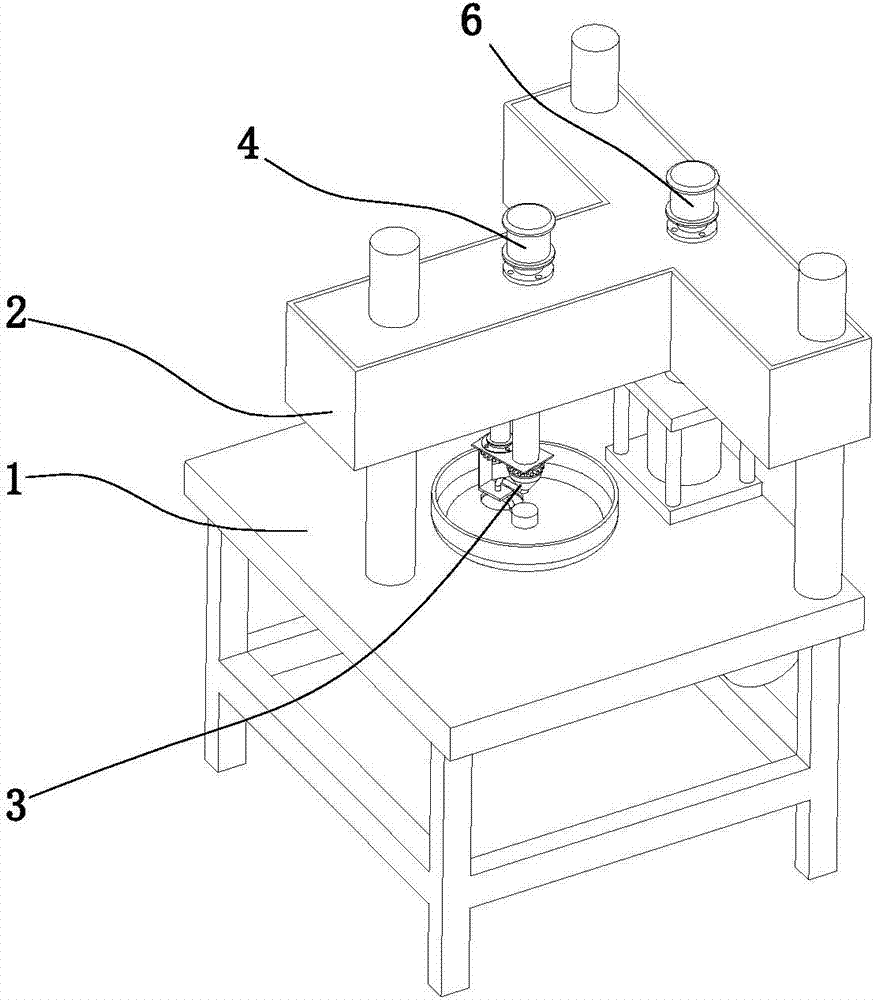

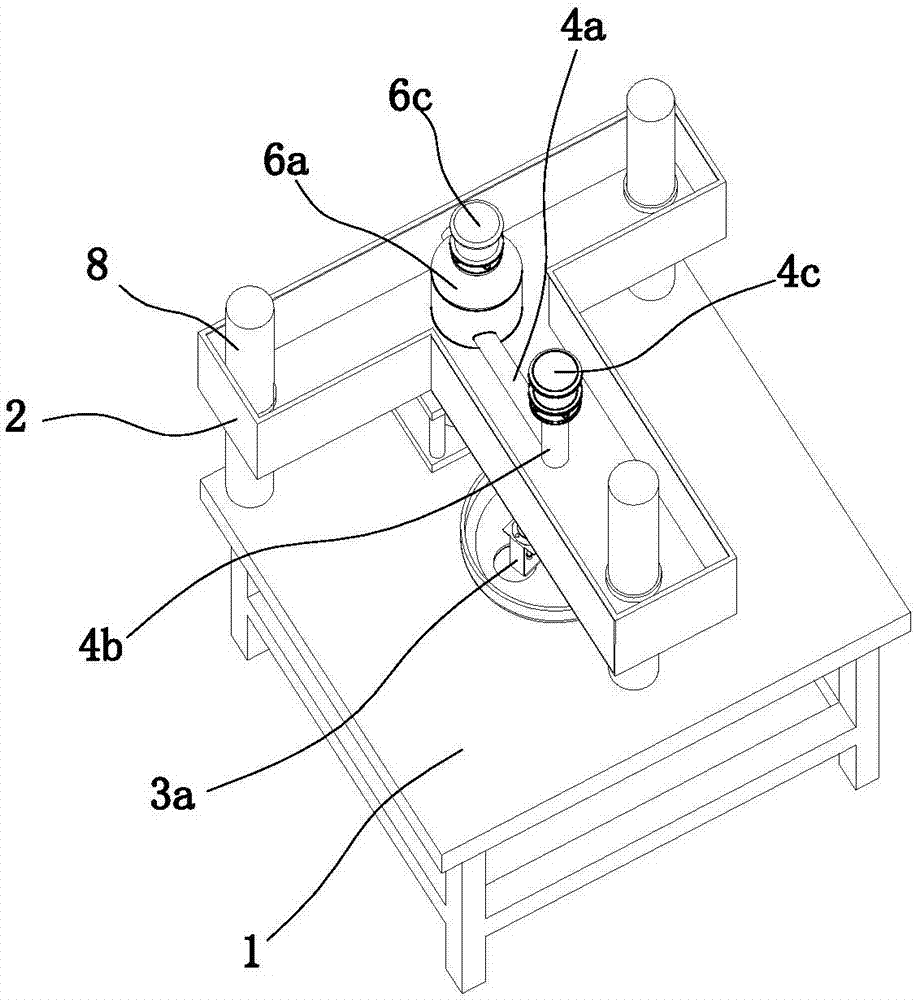

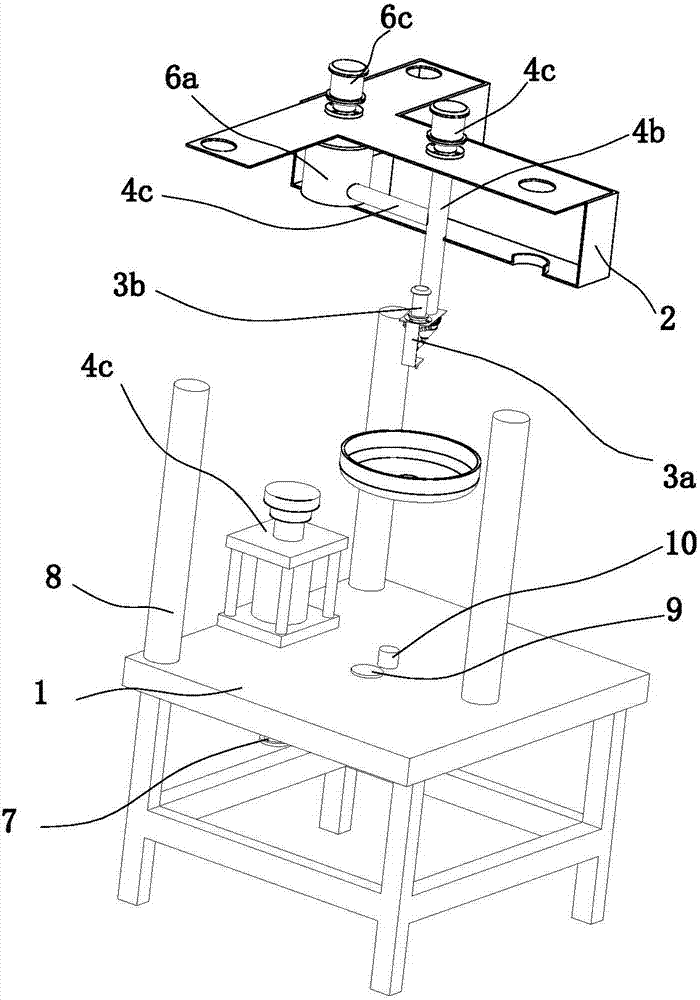

[0024] according to Figure 1 to Figure 6 The solder paste application device shown in the front-end process of welding the exhaust pipe of the upper casing of the air-conditioning compressor includes a base 1, a box body 2, a coating device 3 and a solder paste delivery device 4, and the box body 2 is arranged on the bottom of the base 1 Directly above, the upper end surface of the base 1 is provided with a lifting device 5 that drives the box body 2 to rise and fall, and the box body 2 is provided with a stirring device 6, and the solder paste conveying device 4 includes a horizontal tube 4a, a screw feeding screw 4b and a screw driving mechanism 4c, The two ends of the horizontal pipe 4a are respectively fixedly connected with the screw feed screw 4b and the stirring device 6, the screw feed screw 4b vertically p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com