Pencil board production equipment

A technology for producing equipment and pencil boards, which can be used in unloading equipment, sawing equipment, circular saws, etc., and can solve the problems of long growth cycle and scarcity of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

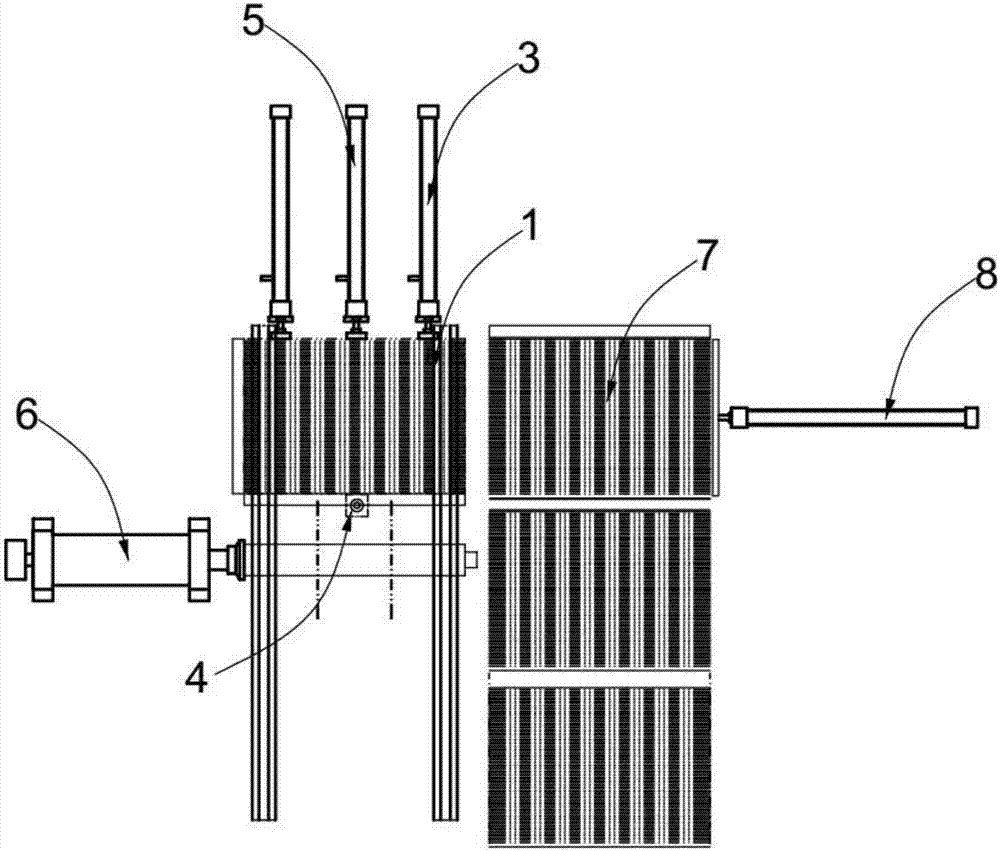

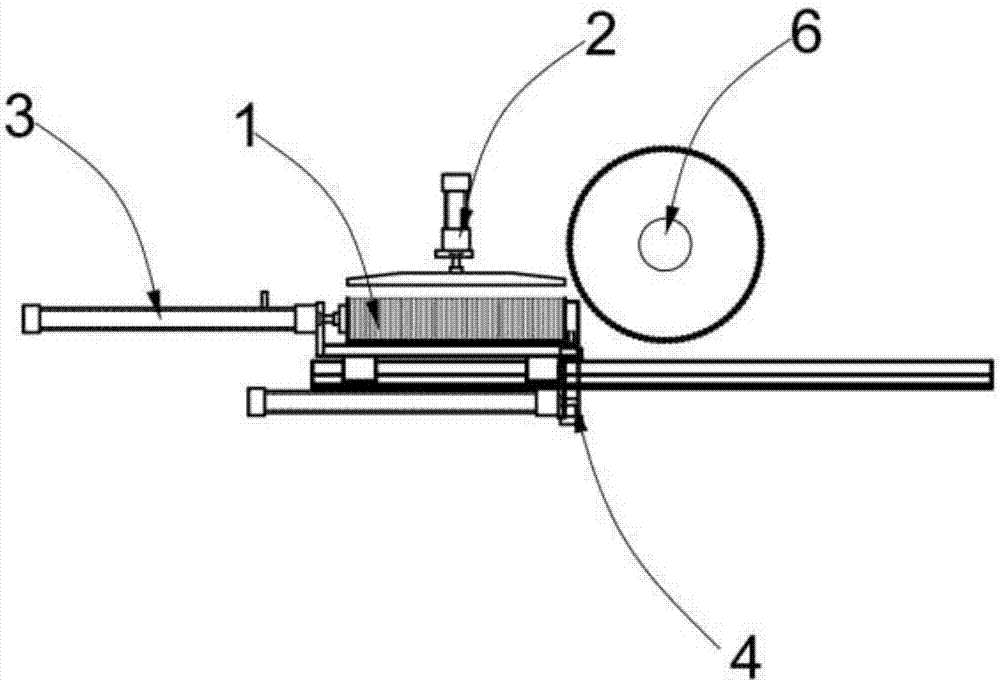

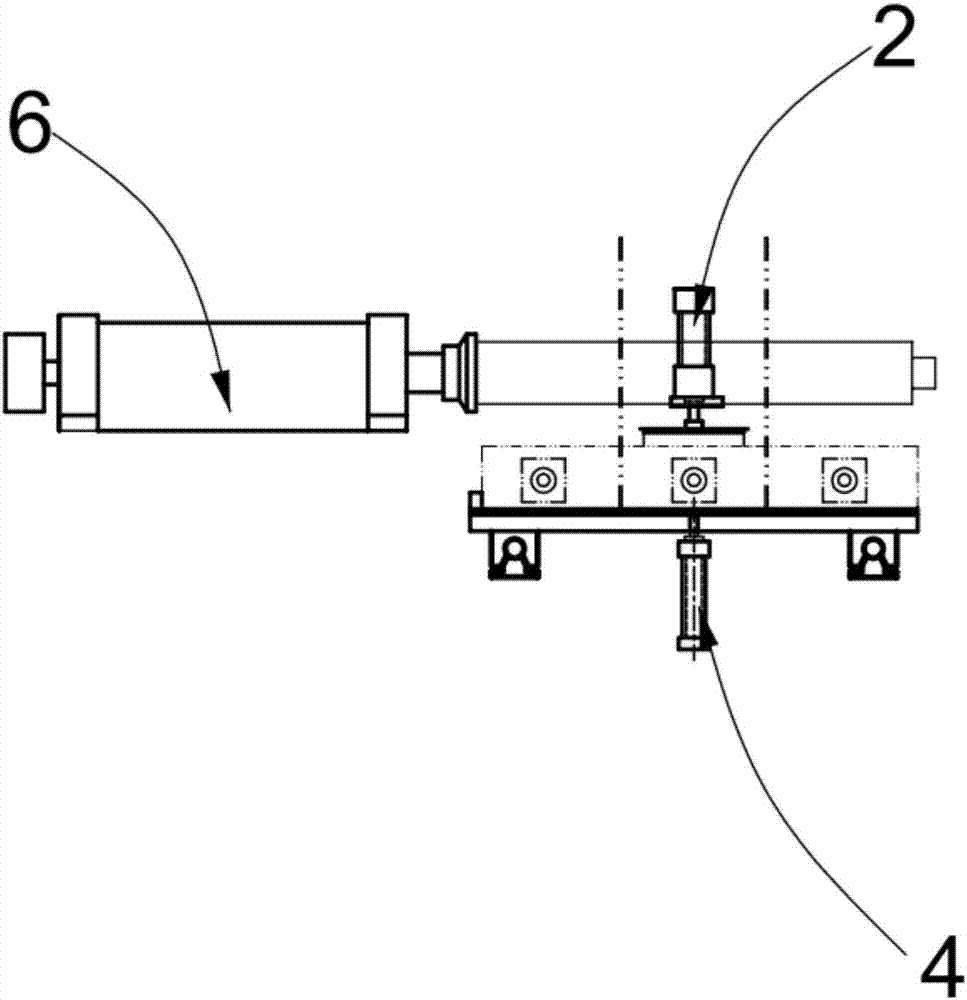

[0019] Such as Figure 1 to Figure 3 As shown, the present invention provides a pencil board production equipment, comprising a main workbench 1, a pressing device 2, a side pressing device 3, a limiting device 4, a material return device 5, and a cutting device 6 thereof, wherein the lowering device The pressing device 2, the side pressing device 3, the limiting device 4, the material return device 5 and the cutting device 6 are all arranged around the main workbench 1. Divided into a long piece of wood with the thickness of a pencil board, the pressing device 2 is used to press down the long piece of wood from above to prevent it from moving up and down, and the side pressure device 3 is used to block the long piece of wood from behind to prevent it from moving backwards. 4 is used to block the long wood chips from the front to prevent forward movement, the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com