3D printing pen

A 3D printing pen and 3D printing technology, applied in 3D object support structures, additive manufacturing, coating devices, etc., can solve the problems of inconvenient handheld operation, troublesome maintenance work, complex product structure, etc., and improve the convenience of handheld operation , Easy maintenance and replacement work, to achieve the effect of maintenance and replacement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

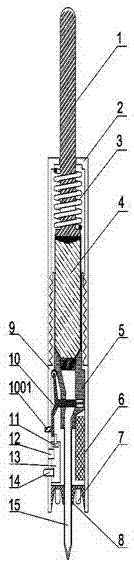

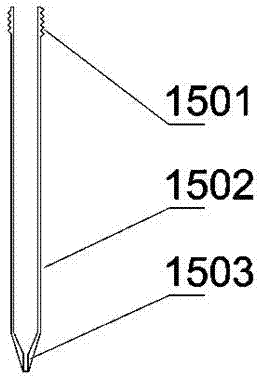

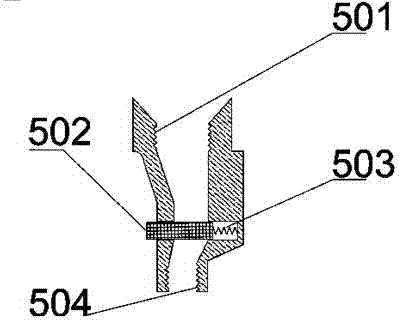

[0024] Such as figure 1 As shown, the 3D printing pen of the present invention includes a pen case and a nib 15 located at the front end of the pen case. The pen case includes an energy storage shell 2 and a 3D printing pen shell 9. The energy storage shell 2 and the 3D printing pen The pen housing 9 is connected by threads. A push rod 1 is movably installed in the energy storage shell 2 at the end of the pen case, and the tail of the push rod 1 protrudes outside the energy storage shell 2, and an energy storage spring 3 is installed on the push rod 1 in the energy storage shell 2, and the push rod 1 1 The head is provided with a piston 401, and extends into the printing material tank 4, such as Figure 4 As shown, the 3D printing material tank 4 is filled with 3D printing material 402 in the casing 403, and the head of the 3D printing material tank 4 is provided with a screw-type sealing installation interface 404. The head of the 3D printing material tank 4 is located at T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com