A biological bed system for treating organic sewage

A technology of organic sewage and biological bed, applied in the field of biological bed system, can solve the problems of low treatment effect, high cost, complicated operation, etc., and achieve the effect of increasing infiltration effect and promoting biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

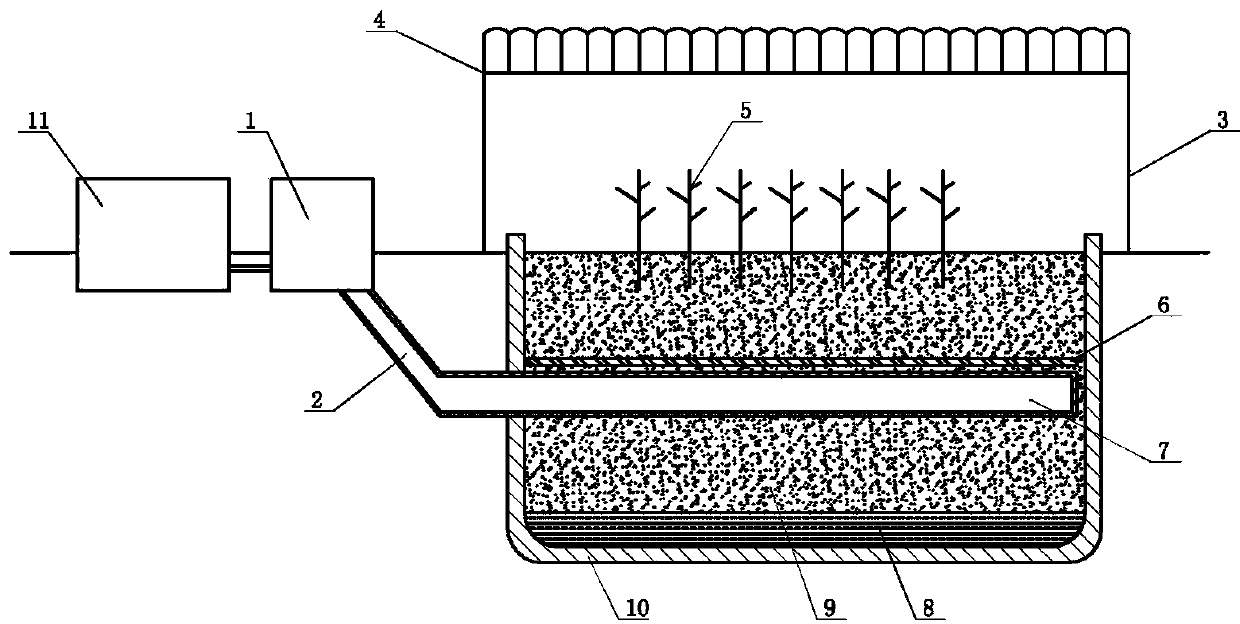

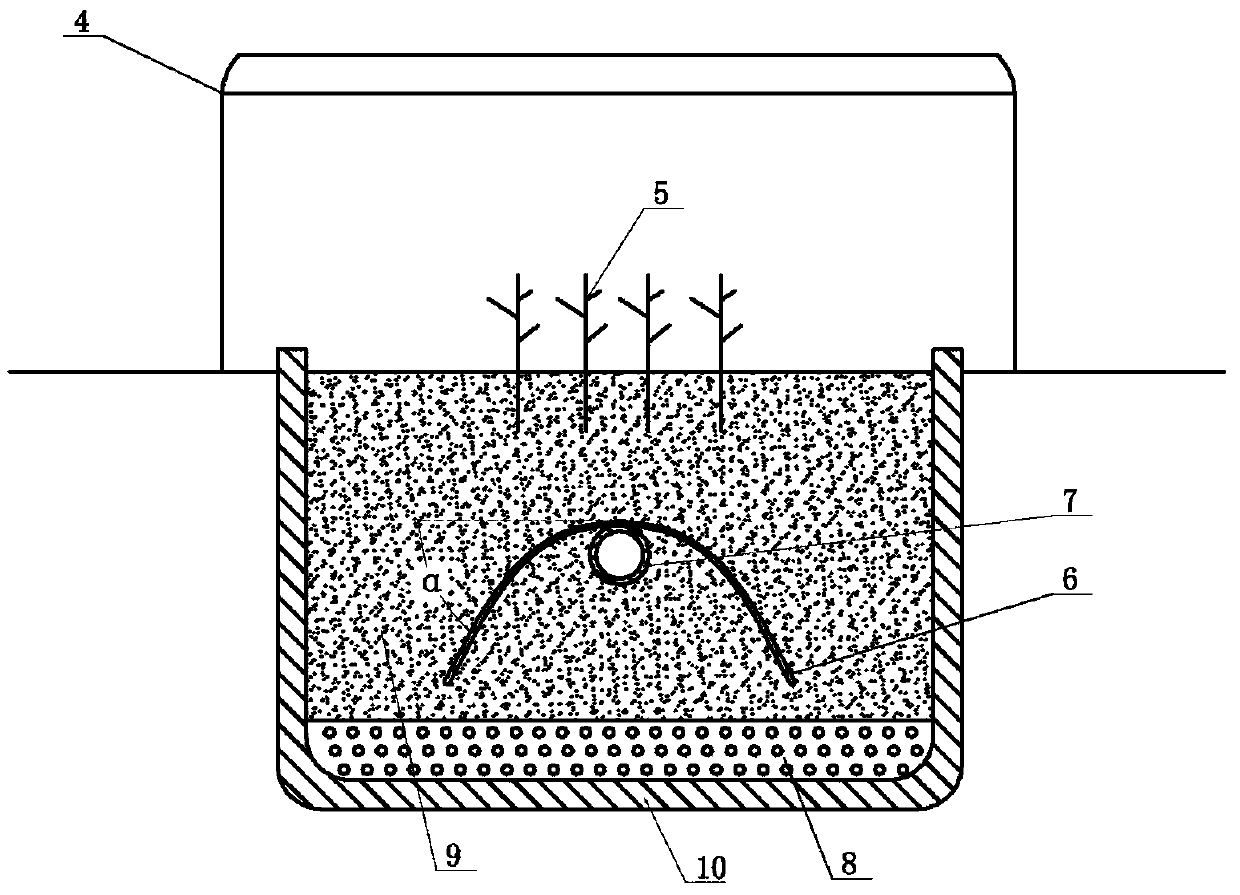

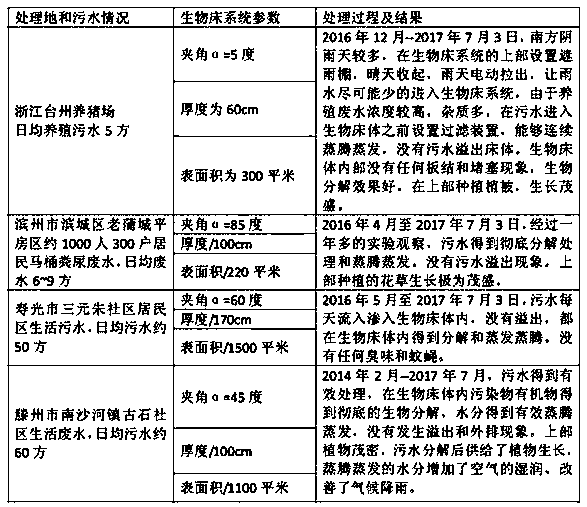

[0063] A biological bed system for treating organic sewage, including a biological bed body with a thickness of 300cm. The bottom and sides of the biological bed body are provided with geomembrane anti-seepage layers. One end of the water pipe is provided with a sewage water inlet, and one end of the sewage water inlet is connected to the filter tank. After being filtered by the filter tank, the organic sewage enters the permeable water pipe through the sewage water inlet. The upper part of the non-woven fabric filter membrane is laid; the two sides of the non-woven fabric filter membrane are inclined straight downward along the length direction of the permeable cloth water pipe, and the angle α between one side of the non-woven fabric filter membrane and the horizontal direction is 5 degrees, and the inclined non-woven fabric The filter membranes are symmetrically distributed on both sides of the permeable water distribution pipe; each cubic meter of sewage is distributed in a...

Embodiment 2

[0069] A biological bed system for treating organic sewage, including a biological bed body with a thickness of 30cm, a geomembrane anti-seepage layer is arranged on the bottom and sides of the biological bed body, and several horizontally distributed water-permeable water pipes are arranged in the middle of the biological bed body, and the water-permeable cloth One end of the water pipe is provided with a sewage water inlet, and one end of the sewage water inlet is connected to the filter tank. After being filtered by the filter tank, the organic sewage enters the permeable water pipe through the sewage water inlet, and the permeable water pipe evenly soaks the organic sewage into the biological bed. The upper part of the cloth water pipe is laid with a non-woven fabric filter membrane; both sides of the non-woven fabric filter membrane are inclined downward along the length of the water-permeable cloth water pipe, and the angle α between the tangent direction of the end of the...

Embodiment 3

[0075] A biological bed system for treating organic sewage, including a biological bed body with a thickness of 100cm. The bottom and sides of the biological bed body are provided with geomembrane anti-seepage layers. One end of the water pipe is provided with a sewage water inlet, and one end of the sewage water inlet is connected to the filter tank. After being filtered by the filter tank, the organic sewage enters the permeable water pipe through the sewage water inlet, and the permeable water pipe evenly soaks the organic sewage into the biological bed. The upper part of the cloth water pipe is laid with a non-woven fabric filter membrane; both sides of the non-woven fabric filter membrane are inclined downward along the length of the water-permeable cloth water pipe, and the angle α between the tangent direction of the end of the non-woven fabric filter membrane and the horizontal direction is 85 degrees , the inclined non-woven fabric filter membrane is symmetrically dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com