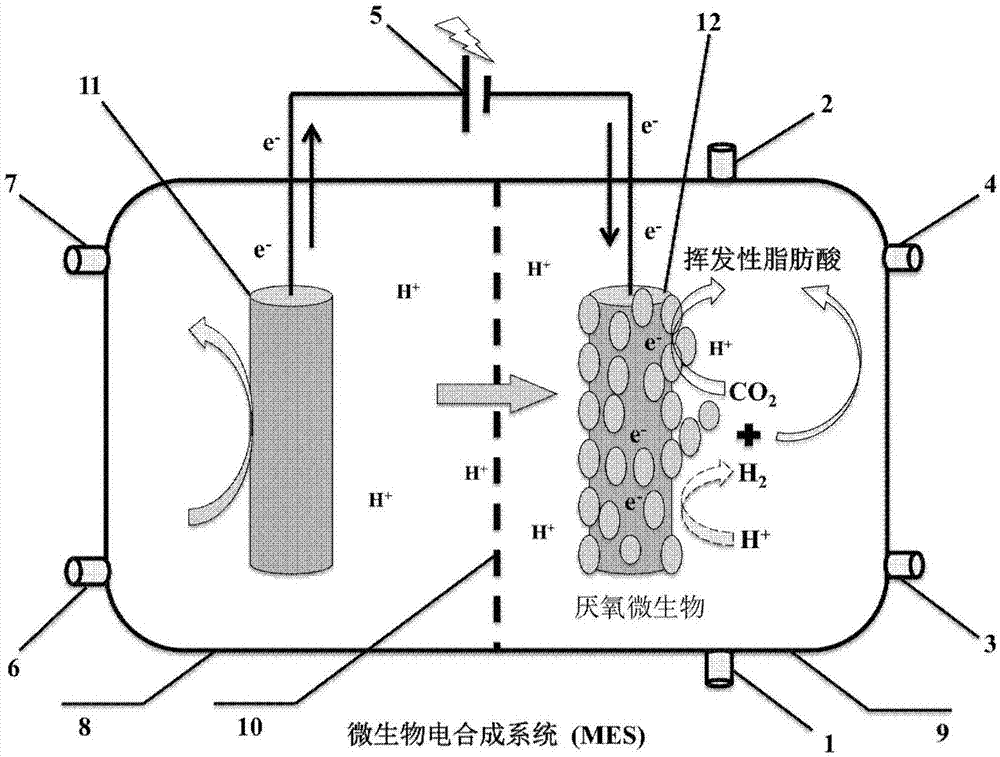

Method for achieving recycling of carbon dioxide through microbial electro-synthesis system

A technology of microbial electrosynthesis and carbon dioxide, applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc., can solve the problems of high energy consumption, expensive catalysts, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

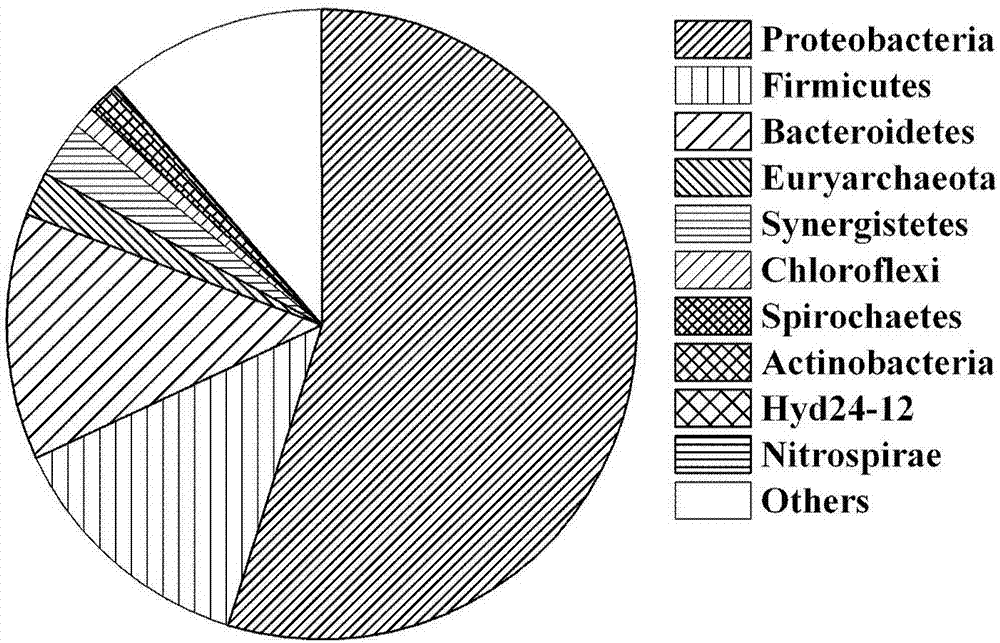

Method used

Image

Examples

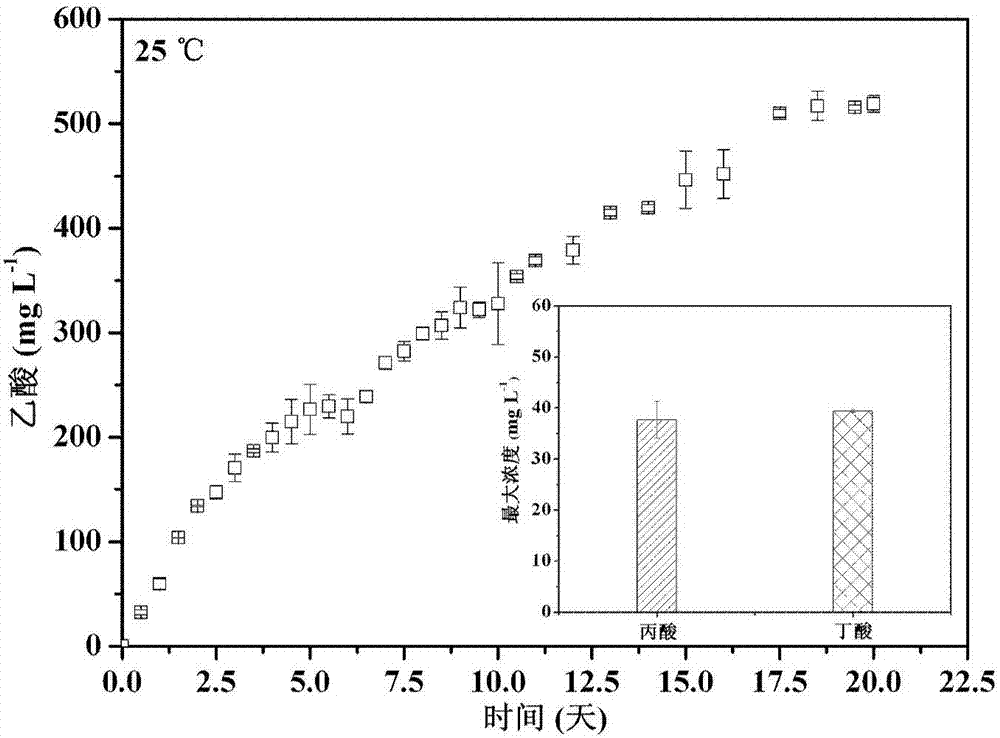

example 1

[0039] Example 1: In the microbial electrosynthesis system of the present invention, when the temperature of the cathode compartment of the MES is controlled at 25°C and the cathode potential is controlled at -0.9V vs. Ag / AgCl / KCl, the maximum amount of acetate produced by the biocathode can reach 519.04mg L -1 , the maximum production of propionic acid and butyric acid can reach 37.71mg L -1 and 39.40mg L -1 .

example 2

[0040] Example 2: In the microbial electrosynthesis system of the present invention, when the temperature of the cathode compartment of the MES is controlled at 35°C and the cathode potential is controlled at -0.9V vs. Ag / AgCl / KCl, the maximum amount of acetate produced by the biocathode can reach 464.79mg L -1 , the maximum production of propionic acid and butyric acid can reach 46.78mg L -1 and 32.20mg L -1 .

example 3

[0041] Example 3: In the microbial electrosynthesis system of the present invention, when the temperature of the cathode compartment of the MES is controlled at 55°C and the cathode potential is controlled at -0.9V vs.Ag / AgCl / KCl, the maximum amount of acetate produced by the biocathode can reach 306.46mg L -1, the maximum production of propionic acid and butyric acid can reach 37.13mg L -1 and 46.38mg L -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com