Inner tub of a washing machine

A washing machine and inner tub technology, applied in the field of washing machines, can solve the problems of less washing water, limited lifting height, and long strokes, and achieve the effects of improving washing effect and efficiency, prolonging service life, and reducing overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

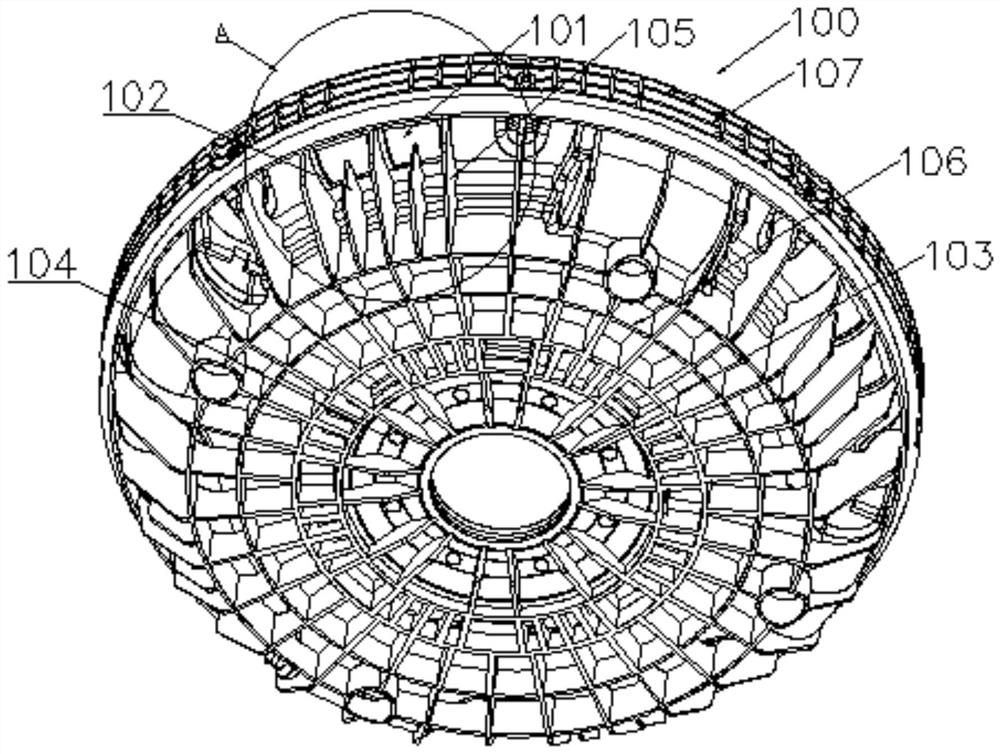

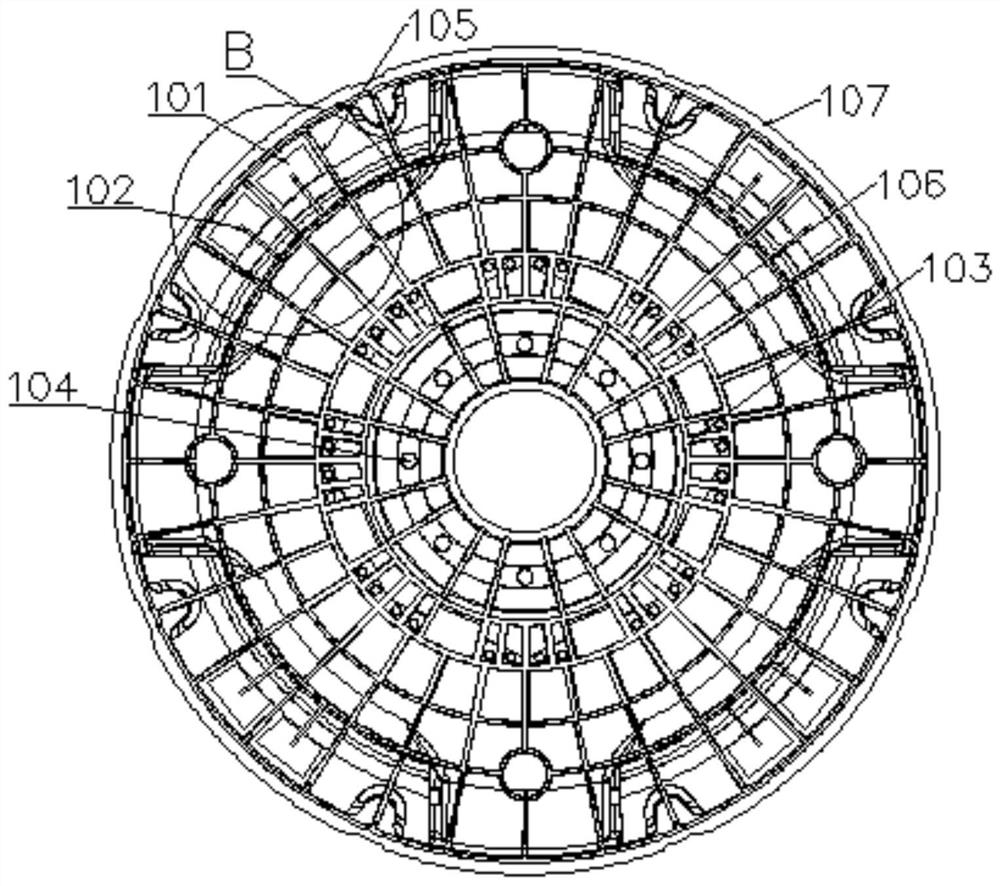

[0034] Such as Figure 1-4 Shown is an inner tub of a washing machine. The washing machine includes an outer tub, an inner tub, and a driving device. The inner tub is arranged in the outer tub, and the driving device is arranged at the lower part of the outer tub. The output end of the driving device is connected to the inner tub to drive the inner tub to rotate. The inner tub includes The inner barrel bottom 100 and the inner barrel body, the inner barrel bottom 100 and the inner barrel body are detachably connected or integrally formed to form an inner barrel together, the inner barrel bottom 100 is provided with a drain port 101 communicating with the outer barrel, and the drain port 101 is provided with a water drain structure,

[0035] During washing, the driving device drives the inner tub to rotate, and the water-repellent structure lifts the washing water discharged from the drain port 101 upward along the inner wall of the outer tub and then falls into the inner tub t...

Embodiment 2

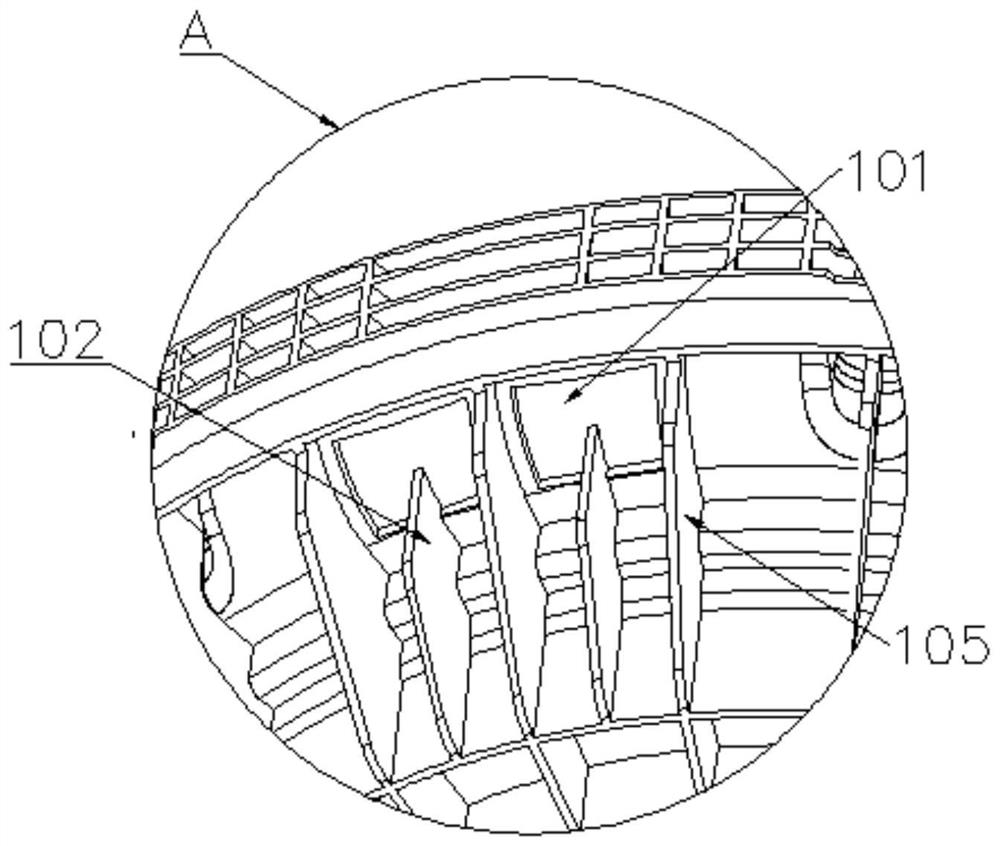

[0039] Such as Figure 1-4 As shown, this embodiment is a further limitation of Embodiment 1. The water-repellent structure includes at least one water-repellent rib 102 protruding from the outer wall of the inner bucket bottom 100, and one end of the water-repellent rib 102 is inserted into the drain 101 .

[0040] Taking one water-repelling rib as an example to explain, the water-repelling rib 102 divides the laundry water discharged from the drain port 101 into two strands, the left and the right, so that the water volume of each strand is further reduced, so that the inner tub can realize the opposite direction at a relatively low speed. The increase of washing water reduces the overheating damage of the motor and prolongs the service life of the washing machine.

[0041] Wherein, the number of water-repelling ribs 102 can be one or more. By setting multiple water-repelling ribs 102 to divide the laundry water into several strands, the quality of a single stream of water ...

Embodiment 3

[0050] Such as Figure 1-4 As shown, on the basis of Embodiment 1 and Embodiment 2, the water outlet 101 in this embodiment is set close to the edge of the inner tub bottom 100 . After the laundry water discharged from the water outlet 101 is directly lifted up along the wall of the outer tub, the stroke is short and the speed loss is small, and an upward water flow effect is generated when the inner tub is lifted and rotated.

[0051] Further, the inner tub bottom 100 is provided with a flange installation area 103 for installing a flange, and the drain port 101 is provided on the inner tub bottom 100 outside the flange installation area.

[0052] Preferably, the flange mounting area 103 is located at the bottom center of the inner barrel bottom 100 .

[0053] Since the flange is generally installed at the center of the inner tub bottom 100 and is far away from the edge of the inner tub bottom 100, the drain outlet 101 is arranged on the inner tub bottom 100 in an area other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com