Brake cable joint of electric vehicle

A technology for electric vehicles and brake lines, applied in the directions of linear motion shafts, bicycle accessories, bicycle brakes, etc., can solve the problems of user inconvenience, unsightly and waste at the wheel and handle, and achieve the effect of preventing slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

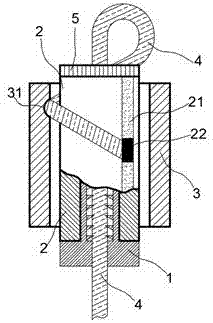

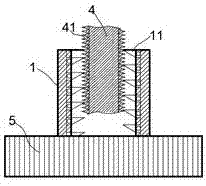

[0018] exist Figure 1 to Figure 3 In the shown embodiment, the electric brake wire connector includes a coaxially sleeved fine adjustment cylinder 1, a coarse adjustment cylinder 2 and a protection cylinder 3; Buckle structure, the cylinders can rotate relative to each other, and cannot slide relative to each other along the shaft; the limit buckle structure is more common, and it can be a matching limit ring structure, or a chute and slip ring matching; for those that do not affect the attached drawings Simple and clear, the limit buckle structure is not shown in the figure;

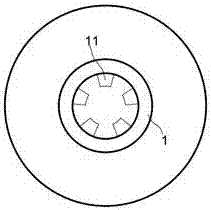

[0019] The brake wire 4 passes through the axis inside the fine-tuning cylinder 1, and the outer wire sleeve 41 of the brake wire 4 fastens the wrapped brake wire 4; The limit teeth 11 are helically arranged on the wall of the cylinder. Viewed from the end face of the fine-tuning cylinder 1, the helically-arranged limit teeth 11 are distributed on the circumference of the inner cylinder wall of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com