Automatic test device for performance of temperature sensor in fire damper and test method

An automatic test and temperature sensor technology, applied in the direction of measuring devices, thermometer testing/calibration, instruments, etc., can solve problems such as interference, detection quality and low efficiency, reduce human interference factors, realize detection automation, and improve detection quality and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

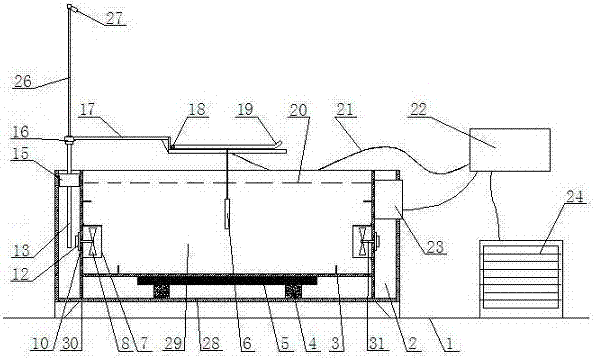

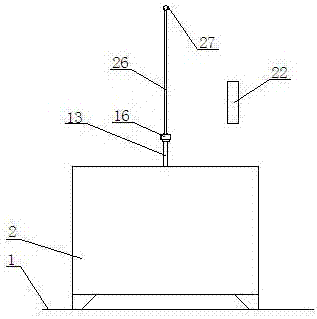

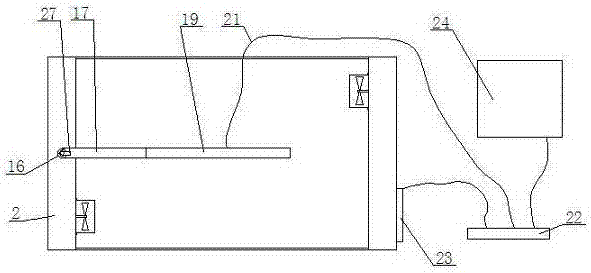

[0024] As attached Figure 1 ~ Figure 3 As shown, this embodiment includes a water bath 2 and a fire damper 24 placed on the platform 1, and a display PLC controller 22.

[0025] The water bath has a water tank 29 for containing water. The water bath has a device for temperature control of the water contained therein. The temperature control device includes a heating unit for heating the water in the water bath and a device for obtaining water temperature data in the water bath. The temperature sensing unit and the temperature control unit respectively connected to the heating unit and the temperature sensing unit to control the water in the water bath at a set temperature range value. The temperature control unit is connected to the control line of the display PLC controller; wherein the heating unit includes a temperature control unit set in the water The electric heating plate 5 in the lower part of the water holding tank 29 of the bath is provided with a fireproof and flame r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com