Holding rail type automatic slip detecting device for tunnel second lining defect detection

A defect detection and detection device technology, which is applied in the direction of measuring devices, electromagnetic wave detection, and re-radiation, can solve the problem of poor coupling between the ground-penetrating radar antenna and the secondary lining concrete surface, the detection radar spectrum cannot meet the detection results, and high-altitude operations Insufficient security and other issues, to achieve the effect of reducing manual labor intensity, reducing human interference factors, and improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

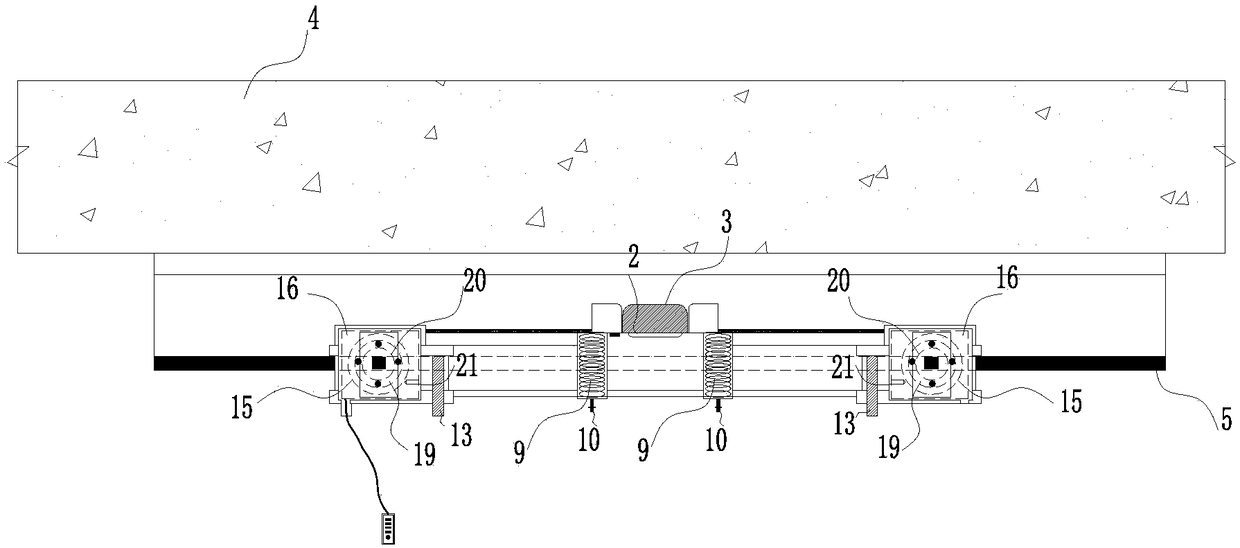

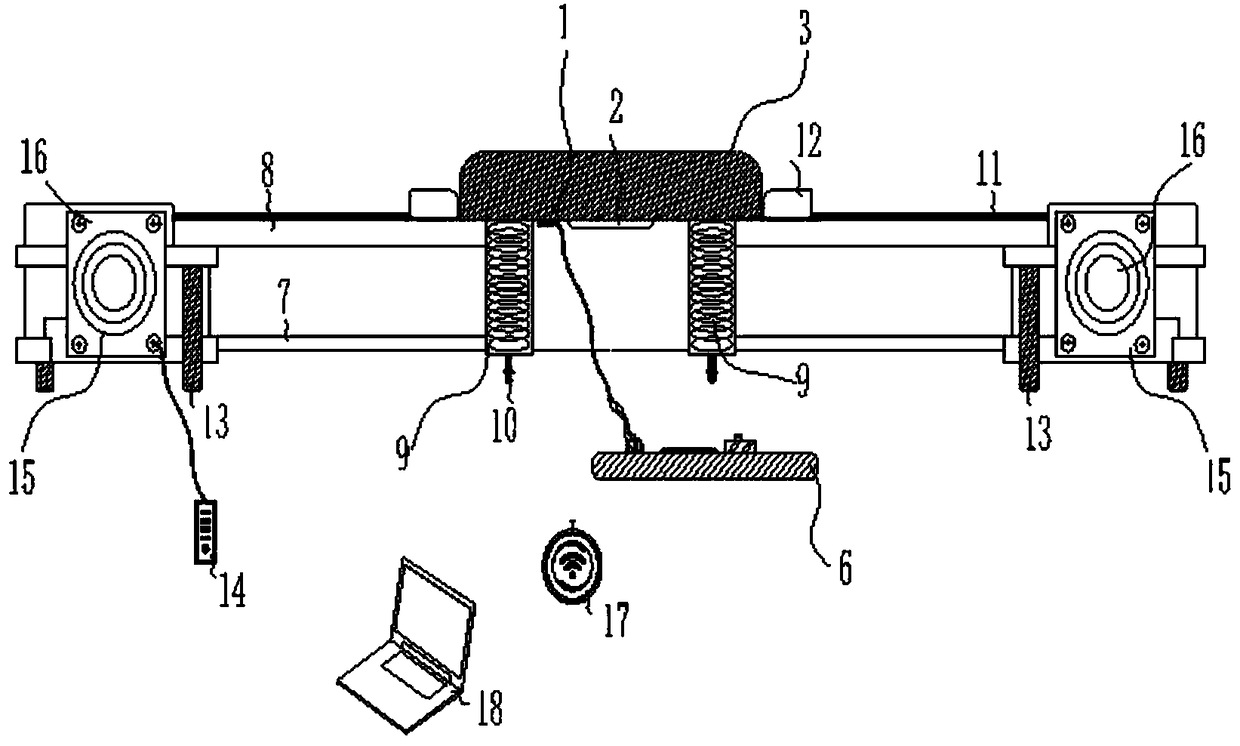

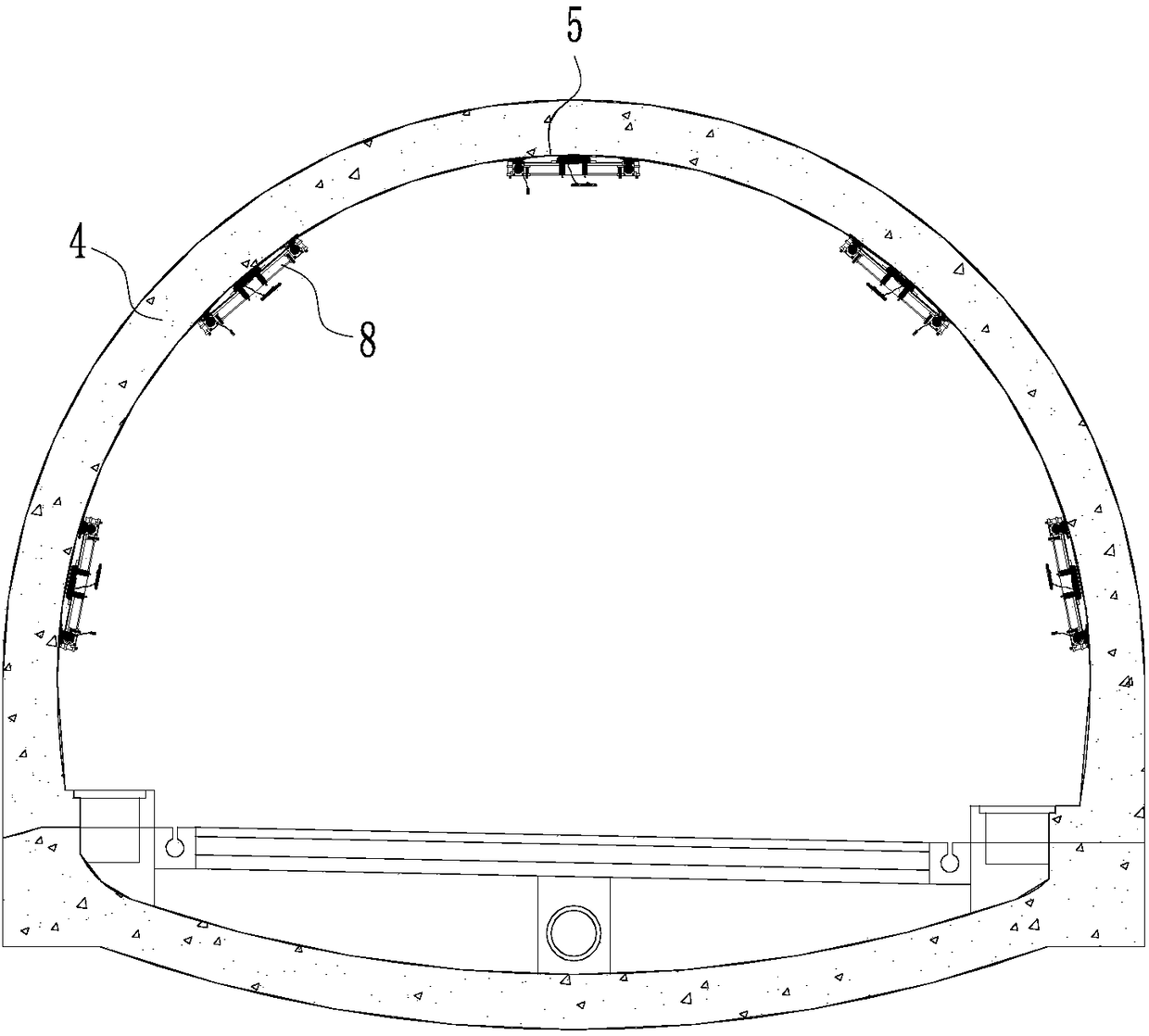

[0032] A rail-holding type automatic slip detection device for detecting defects in the second lining of the tunnel, the detection device includes a ball guide rail 5, a body bracket 8, and an adjustable pressing assembly and a driving brake assembly installed on the body bracket 8 , distance measuring component and ground penetrating radar antenna component; the ball guide rail 5 is fixed and installed on the tunnel vault, both sides of the arch waist and the side walls of the tunnel through nuts; the body bracket 8 is connected by bolts and is in the shape of a cuboid; the pressure can be adjusted The tightening assembly includes an adjustable frame 7, a compression spring 9, a compression nut 10, and an adjustment screw 13; the middle part of the adjustable frame 7 is provided with several compression springs 9, the bottom of the compression spring 9 is provided with a compression nut 10, and the adjustable frame 7 Adjusting screw rods 13 are provided at both ends, and the a...

Embodiment 2

[0036] The difference from Embodiment 1 is that the adjustable compression assembly is also provided with a sliding compression spring 11 and a sliding compression block 12 , which are installed on the left and right sides of the shielded antenna 3 . It is used to fix the shielded antenna 3 on the body bracket 8, and it is also convenient to adjust the shielded antenna 3 left and right.

Embodiment 3

[0038]The difference from Embodiment 2 is that the ground penetrating radar antenna assembly is also provided with a wireless receiving module 17 , and the radar host 6 transmits the collected radar spectrum to a notebook computer 18 through the wireless receiving module 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com