Planning and design method for polyester fiber tension type mooring system

A technology of polyester fiber and mooring system, applied in the field of deep water marine engineering, can solve the problem of not providing mooring system and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

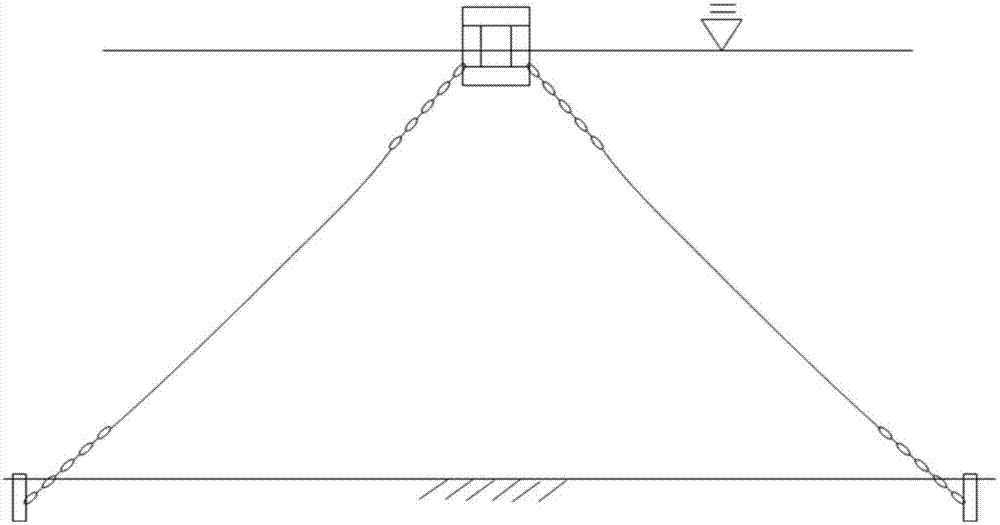

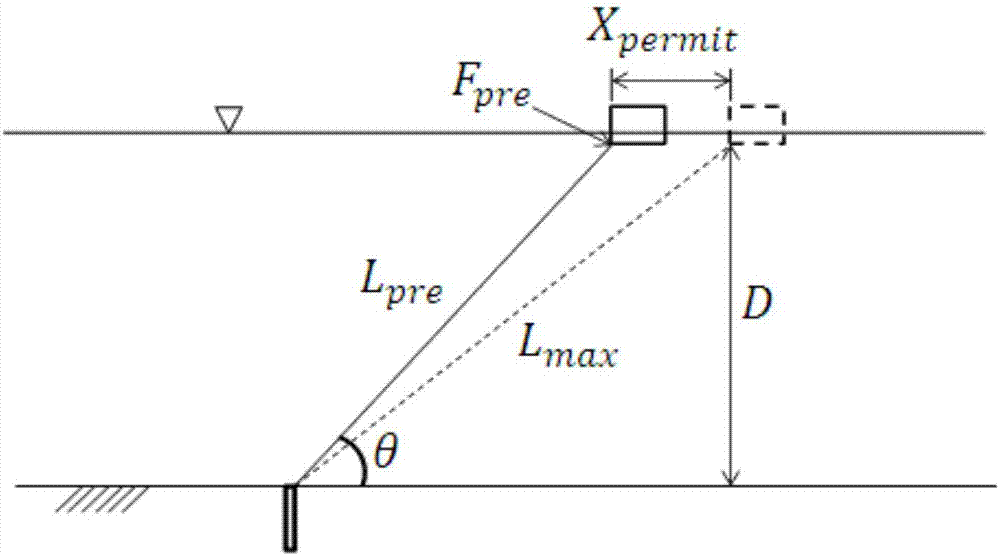

[0050] The present invention uses a normal load-bearing anchor as a foundation, so the anchor point will bear a vertically upward load. Such as figure 1 As shown, the planning and design method of the polyester fiber tension type mooring system provided by the present invention comprises the following steps:

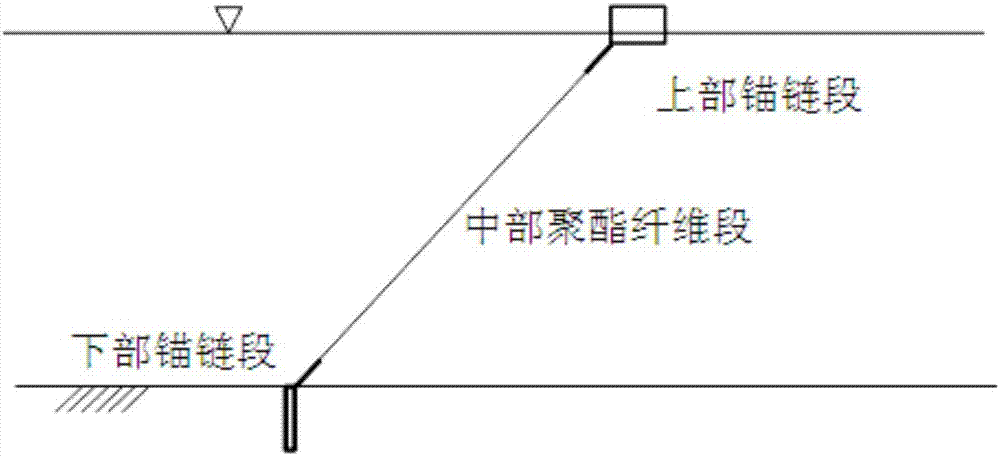

[0051] 1. Select a polyester fiber cable and anchor chain of a certain specification as the material for each cable segment in the mooring system, and determine the segmental structure of each cable in the mooring system. The specific process is as follows:

[0052] 1) Select a polyester fiber cable of a certain specification, and obtain the upper limit, lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com