Screen plate capable of solving BGA four-corner short circuit and manufacturing method

A manufacturing method and stencil technology, which are applied in the directions of printed circuit manufacturing, printed circuits, printed circuits, etc., to achieve the effect of reducing the short-circuit defect rate, reducing costs, and solving the short-circuit defect problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

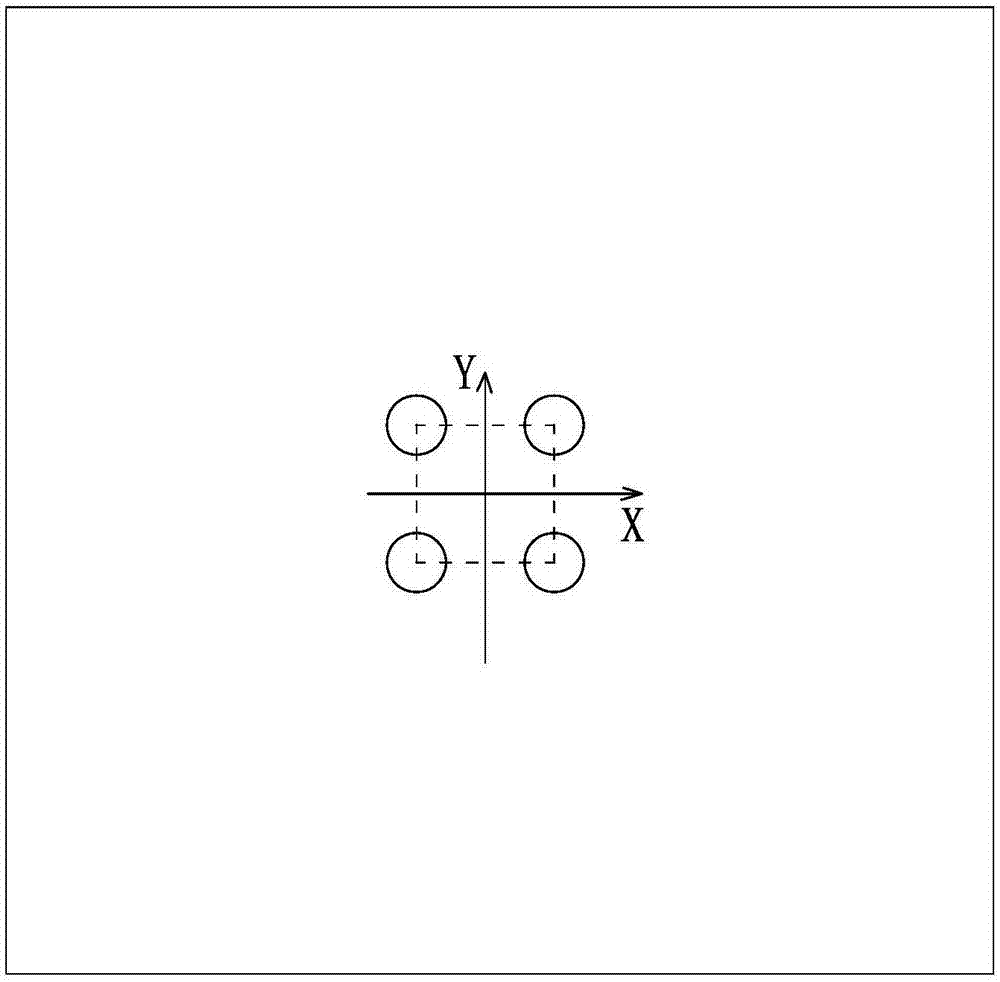

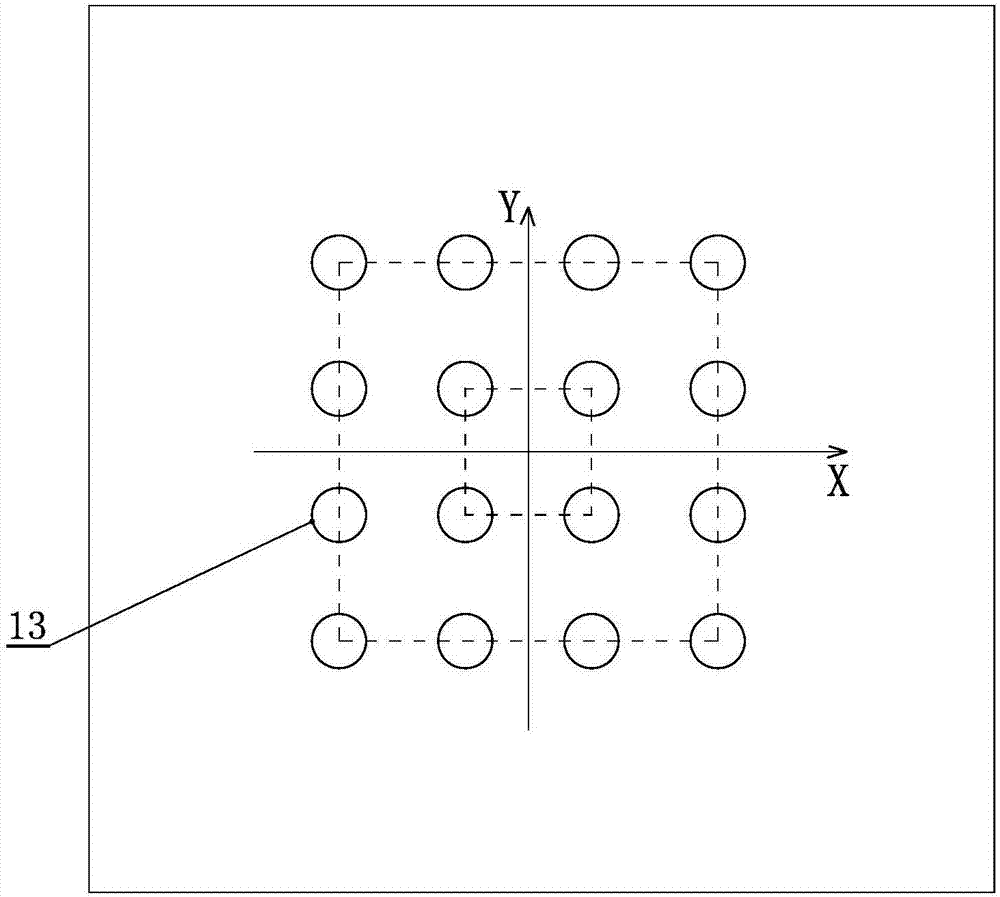

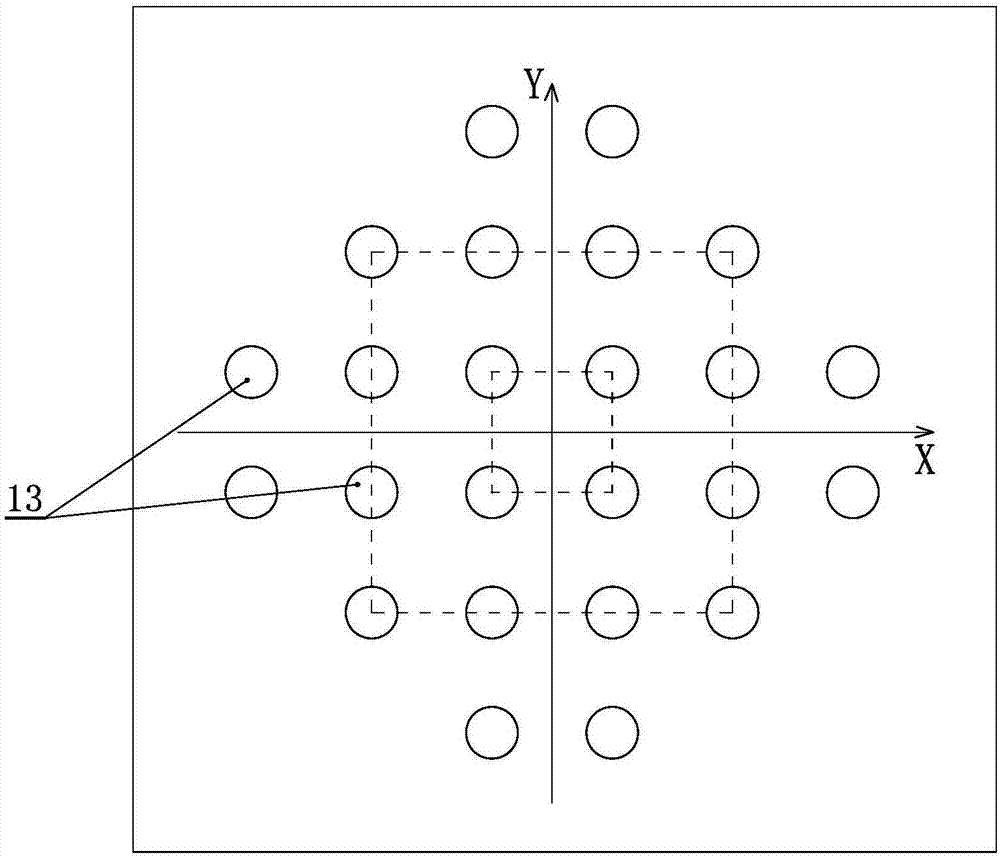

[0027] like Figure 1-Figure 5 As shown, the center of the screen plate 14 of this invention includes four holes, and the connecting lines of the centers of the four holes form a first rectangular circle, and corresponding to the first rectangular circle, there are several rectangular circles that diverge outwards, and the holes on the screen plate 14 are defined as sides respectively. Holes, secondary corner holes and corner holes, the corner holes are the holes distributed in the four corners of each rectangular circle, the secondary corner holes are the holes close to the four corner holes of each rectangular circle, and the other holes of each rectangular circle are side holes 13; The secondary corner ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com