Automated cultivation apparatus

A technology of equipment and cultivated land, which is applied in the field of automated cultivated land equipment, can solve problems such as equipment damage, and achieve the effect of improving the effect, making the process simple and convenient, and increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

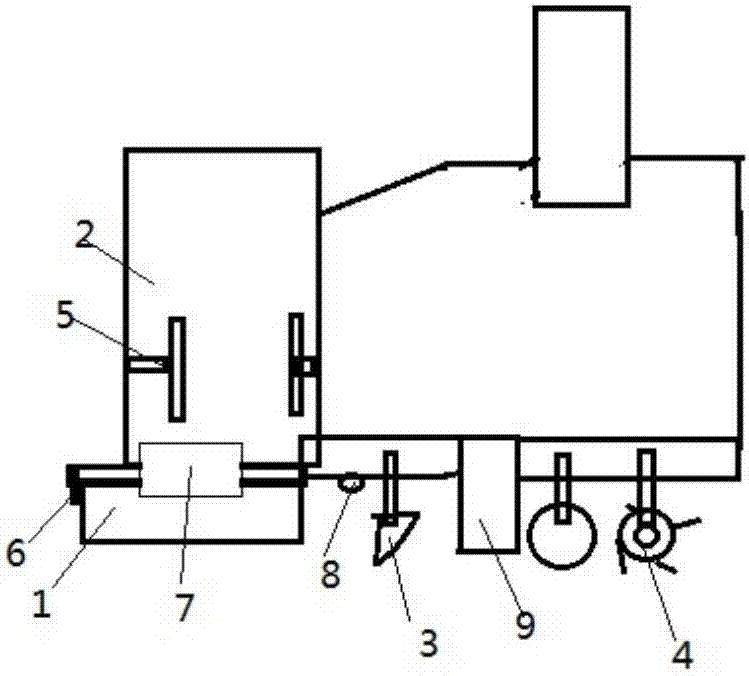

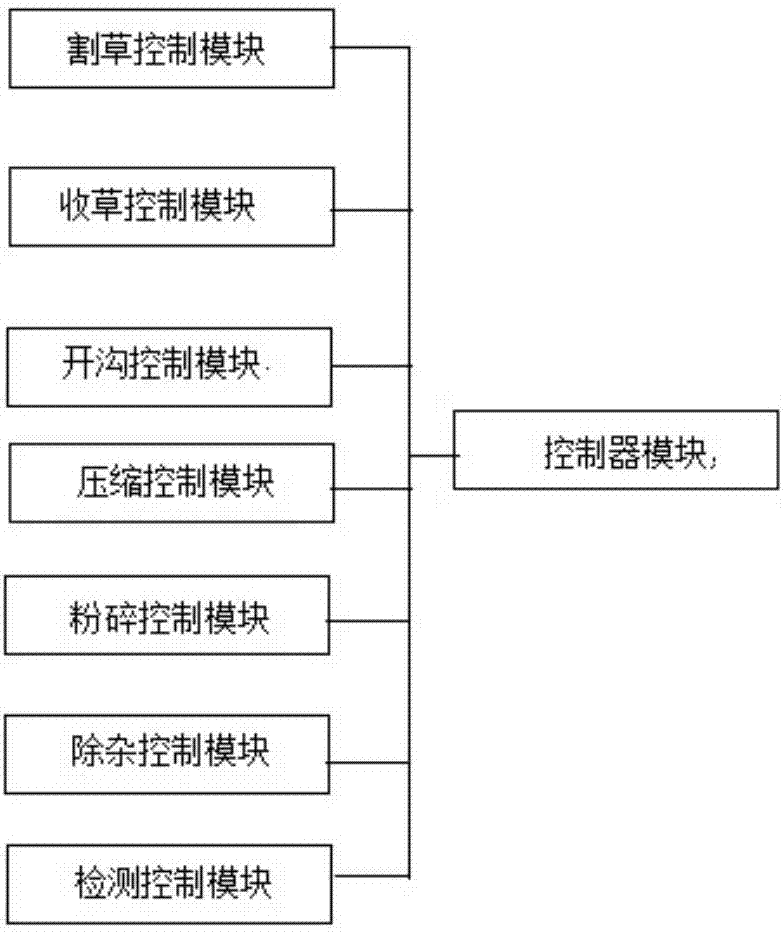

[0024] An automatic farming equipment as shown in the figure, including: a mowing mechanism 1, a grass harvesting mechanism 2, a ditching mechanism 3, a silt mechanism 4 and a control mechanism;

[0025] The relationship between the above components is as follows:

[0026] The mowing mechanism 1, the grass harvesting mechanism 2, the ditching mechanism 3 and the silt mechanism 4 are all arranged on the plowing equipment body, the grass harvesting mechanism 2 is located above the mowing mechanism 1, and the ditching mechanism 3 And the silt mechanism 4 is arranged at the rear of the mowing mechanism 1 in turn, and the mowing mechanism 1, the grass collecting mechanism 2, the ditching mechanism 3 and the silt mechanism 4 are all connected with the control mechanism.

[0027] In this embodiment, the grass harvesting mechanism 2 is provided with a compression mechanism 5 , and the compression mechanism 5 is arranged at the entrance of the grass harvesting mechanism 2 .

[0028] I...

Embodiment 2

[0036] An automatic farming equipment as shown in the figure, including: a mowing mechanism 1, a grass harvesting mechanism 2, a ditching mechanism 3, a silt mechanism 4 and a control mechanism;

[0037] The relationship between the above components is as follows:

[0038] The mowing mechanism 1, the grass harvesting mechanism 2, the ditching mechanism 3 and the silt mechanism 4 are all arranged on the plowing equipment body, the grass harvesting mechanism 2 is located above the mowing mechanism 1, and the ditching mechanism 3 And the silt mechanism 4 is arranged at the rear of the mowing mechanism 1 in turn, and the mowing mechanism 1, the grass collecting mechanism 2, the ditching mechanism 3 and the silt mechanism 4 are all connected with the control mechanism.

[0039] In this embodiment, the grass harvesting mechanism 2 is provided with a compression mechanism 5 , and the compression mechanism 5 is arranged at the entrance of the grass harvesting mechanism 2 .

[0040] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com