Structure of leg prosthesis

A prosthetic leg and transmission mechanism technology, applied in prosthetics, artificial legs, medical science, etc., can solve problems such as single knee-ankle angle relationship, gap in walking gait, and occasions that cannot adapt to active torque, and achieve simplified control methods, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

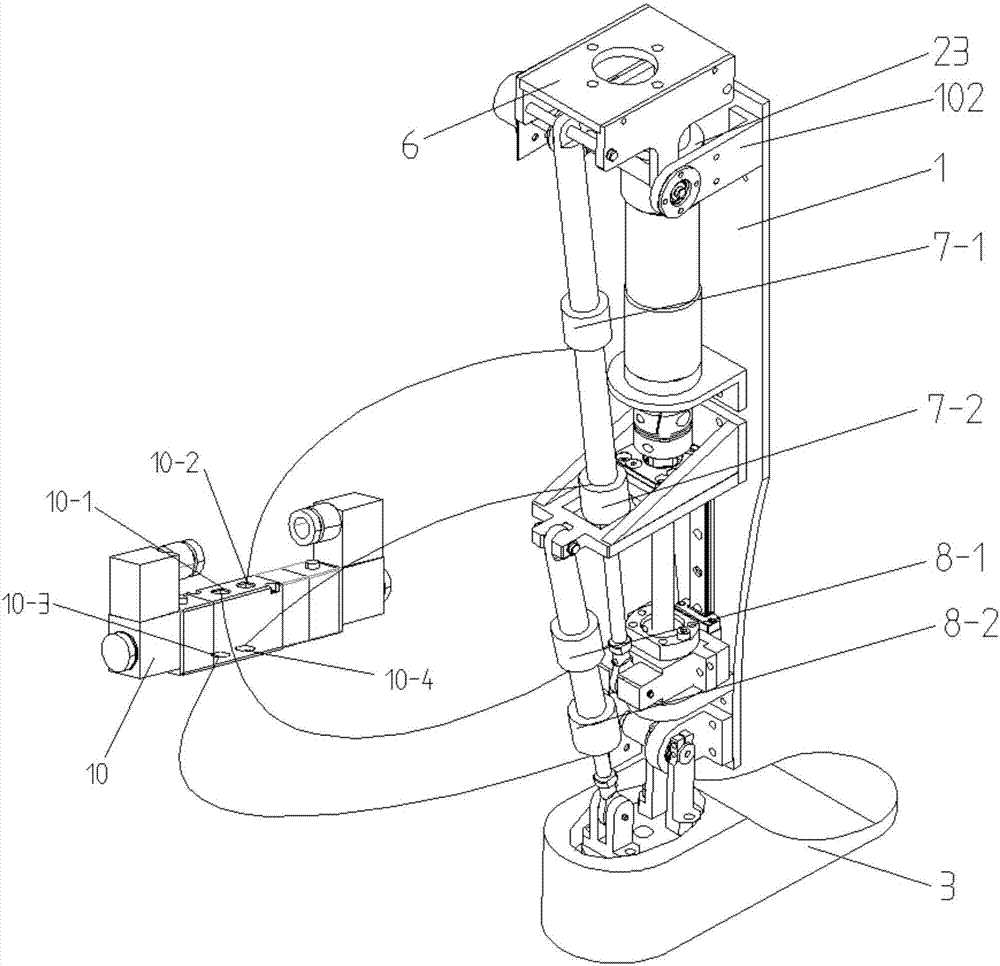

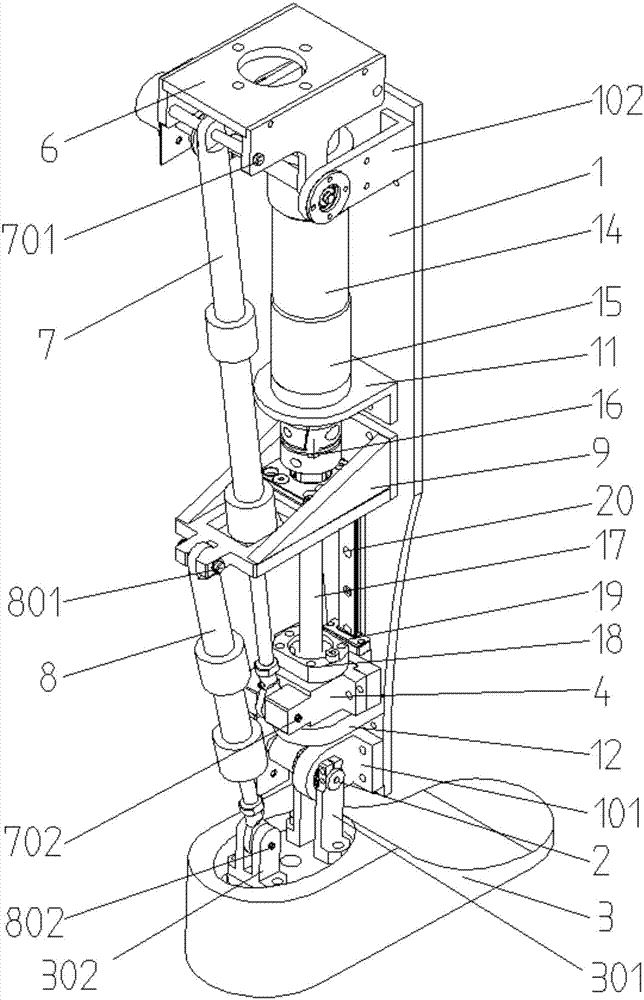

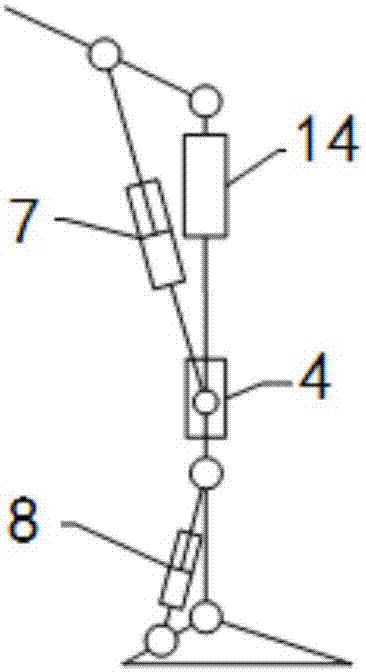

[0039] see figure 1 and Figure 7, a prosthetic leg structure according to a preferred embodiment of the present invention, comprising a base plate 1 for installing most parts, a foot plate 3 that is rotationally connected with the base plate 1 through a first rotating shaft 2, placed on the base plate 1 on the drive mechanism. In this embodiment, the preferred connection mode between the foot plate and the base plate is as follows: set the foot plate support seat 301 on the foot plate, set the ankle joint support seat 101 on the base plate, and pass between the ankle joint support seat 101 and the foot plate support seat 301 through a first The rotating shaft 2 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com