Temperature control-material feeding coupled zone fritting furnace

A technology of coupling area and sintering furnace, used in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of inability to obtain performance, different sintering characteristics, and good sintered bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

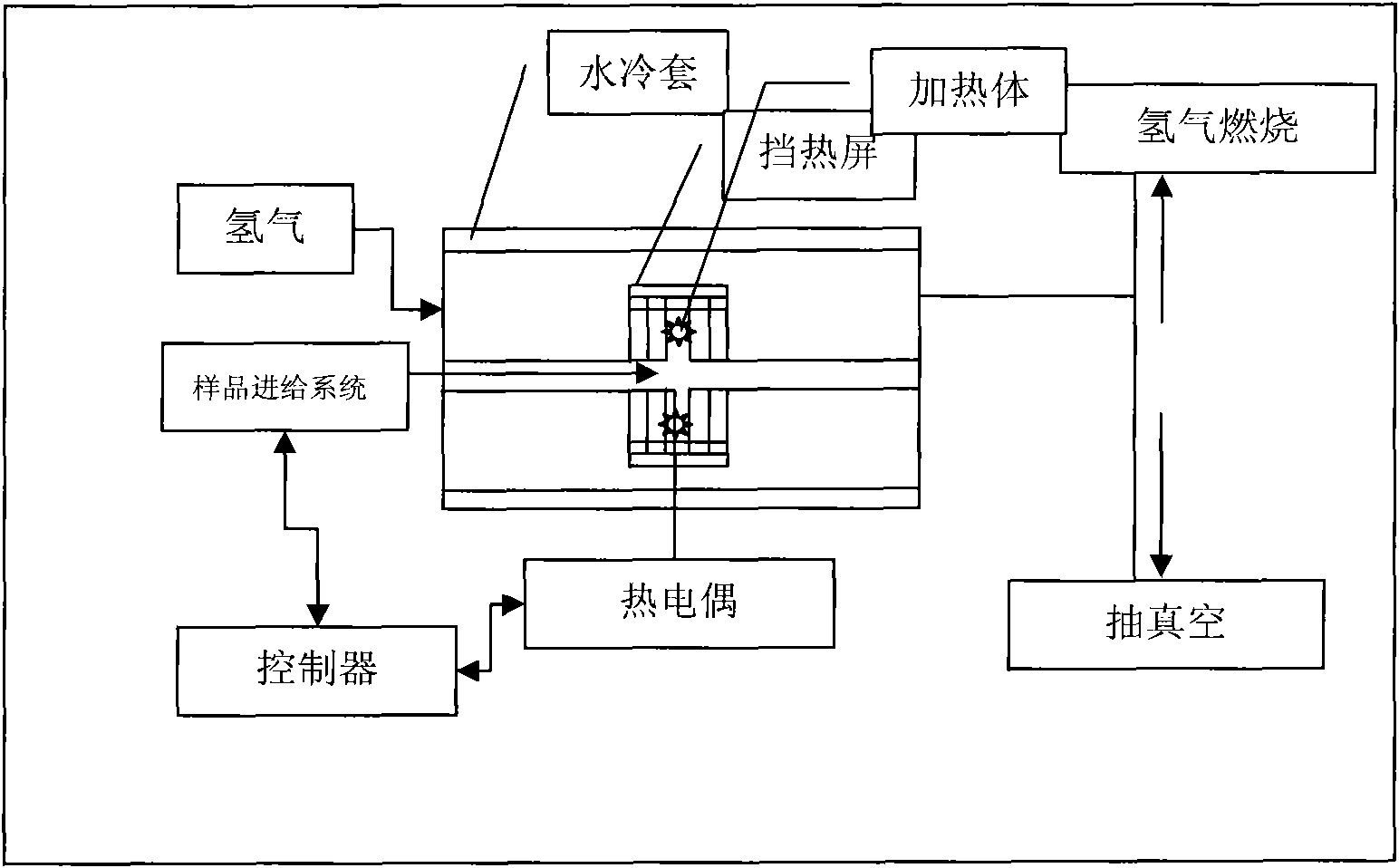

[0020] The function of the sintering furnace of the present invention is to form the required powder into a gradient material of a certain shape according to the requirements. Under vacuum conditions and at a certain material feeding speed, the furnace temperature program is controlled to realize the relationship between the temperature of the furnace body and the sintering temperature of the material. Coupling, sintering to prepare transparent ceramic gradient materials. mainly includes:

[0021] (1) Vacuum system, used to generate the vacuum required for the preparation of transparent ceramics;

[0022] (2) The heating system generates the required temperature through PID control;

[0023] (3) The cooling system takes away the excess heat generated by the heating system, and can also generate a certain temperature field;

[0024] (4) The material feeding system controls the material feeding speed through the control system to realize the coupling of the furnace body temper...

Embodiment 2

[0028] The function of the sintering furnace of the present invention is to form the required powder into a gradient material of a certain shape according to the requirements, and to control the furnace temperature program under a hydrogen atmosphere and a certain material feeding speed to realize the relationship between the temperature of the furnace body and the sintering temperature of the material. Coupling, sintering to prepare transparent ceramic gradient materials. mainly includes:

[0029] (1) hydrogen gas flow controller, in order to produce the required hydrogen atmosphere for preparing transparent ceramics;

[0030] (2) The heating system generates the required temperature through PID control;

[0031] (3) The cooling system takes away the excess heat generated by the heating system, and can also generate a certain temperature field;

[0032] (4) The material feeding system controls the material feeding speed through the control system to realize the coupling of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com