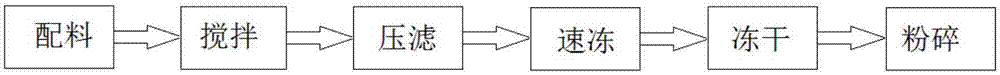

Production system of composite thermal stabilizer for plastic steel and processing technique of production system

A composite thermal stabilizer and production system technology, which is applied in the fields of filtration and separation, chemical instruments and methods, and separation methods, can solve the problems of poor stabilization effect of calcium-zinc thermal stabilizer and long processing cycle, and reduce dehydration energy consumption , Increase the filter press device and press filter steps, and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

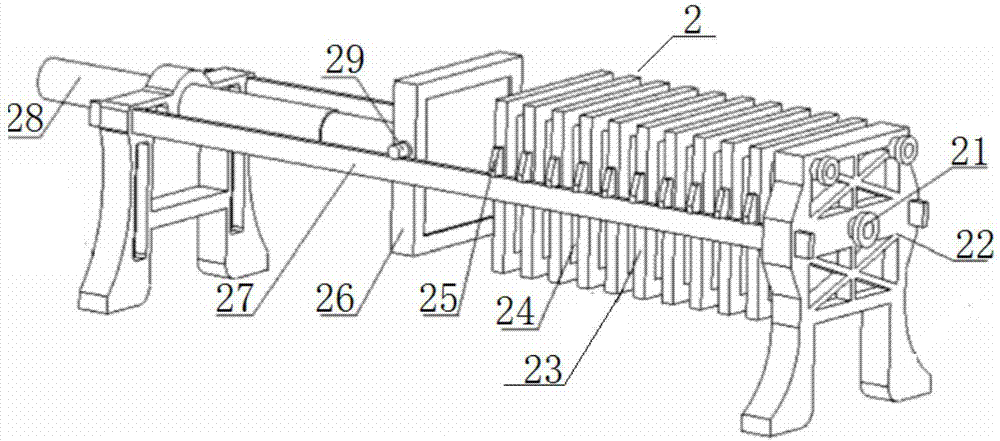

[0043] The composite heat stabilizer production system for plastic steel of the present embodiment comprises a stirring device, a filter press device 2, a drying device 3 and a pulverizing device arranged and connected in sequence according to the technological process; wherein: the filter press device 2 is interposed between the stirring device and the Between the drying devices 3; the filter press device 2 includes support seats at the front and rear ends and two support beams 27 parallel to each other connecting the two support seats; a thrust plate 22 is arranged on the front end support seats, so The thrust plate 22 is provided with a through feeding hole 21; the rear support base is horizontally fixed with a hydraulic cylinder 28, the hydraulic cylinder 28 is provided with a piston rod, and the front end of the piston rod is fixed with a compression plate 26, the pressing plate 26 is located between two support beams 27; on the two support beams 27, a plurality of filter ...

Embodiment 2

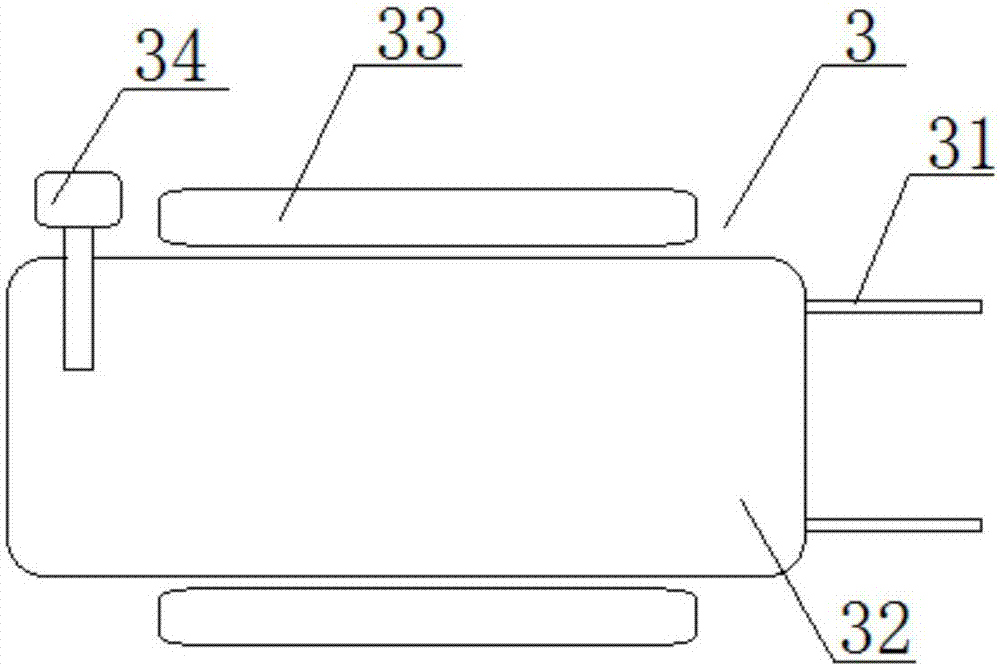

[0053] The composite heat stabilizer production system for plastic steel of the present embodiment, the basic structure is the same as that of embodiment 1, and the differences and improvements are as follows: image 3 As shown, the drying device 3 is a vacuum freeze-drying device, and the vacuum freeze-drying device includes an inlet and outlet guide rail 31, a freeze-drying warehouse 32, a cold trap 33 and a vacuum pump 34; Connection; the cold trap 33 is placed outside the freeze-drying warehouse 32, and the two are communicated through pipelines; the vacuum pump 34 is also communicated with the freeze-drying warehouse 32 through pipelines.

[0054] Composite heat stabilizer for plastic steel of the present embodiment, basic batching is the same as embodiment 1, difference and improvement are: the component of its batching comprises the paraffin of each 40 weight parts of calcium palmitate and zinc palmitate, each 10 weight parts And glacial acetic acid, and each 8 parts by...

Embodiment 3

[0064] The composite heat stabilizer production system for plastic steel of the present embodiment, the basic structure is the same as embodiment 3, the difference and improvement are: two support slide blocks 25 are symmetrically arranged on the both sides of the filter plate 23; The block 25 slides back and forth on the upper surface of the support beam 27; two support rollers 29 are symmetrically arranged on the both sides of the pressing plate 26; Efficiency and achieve labor-saving effect.

[0065] Composite heat stabilizer for plastic steel of the present embodiment, the component of its batching includes each 35 weight parts of calcium palmitate and zinc palmitate, each 6 weight parts of paraffin and glacial acetic acid, and each 7 weight parts of stearyl benzene Formylmethane and Octanoylbenzoylmethane.

[0066] The composite stabilizer of this embodiment is applied to the production of plastic steel profiles, and the addition amount is 3%. After testing, the obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com