A neutralization process in the preparation process of electrolytic manganese dioxide

A technology for electrolytic manganese dioxide and preparation process, applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., can solve the problems of reducing manganese recovery rate, large input of calcium carbonate, reducing manganese recovery rate, etc. The effect of adsorption capacity, reduction of impurities, and reduction of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

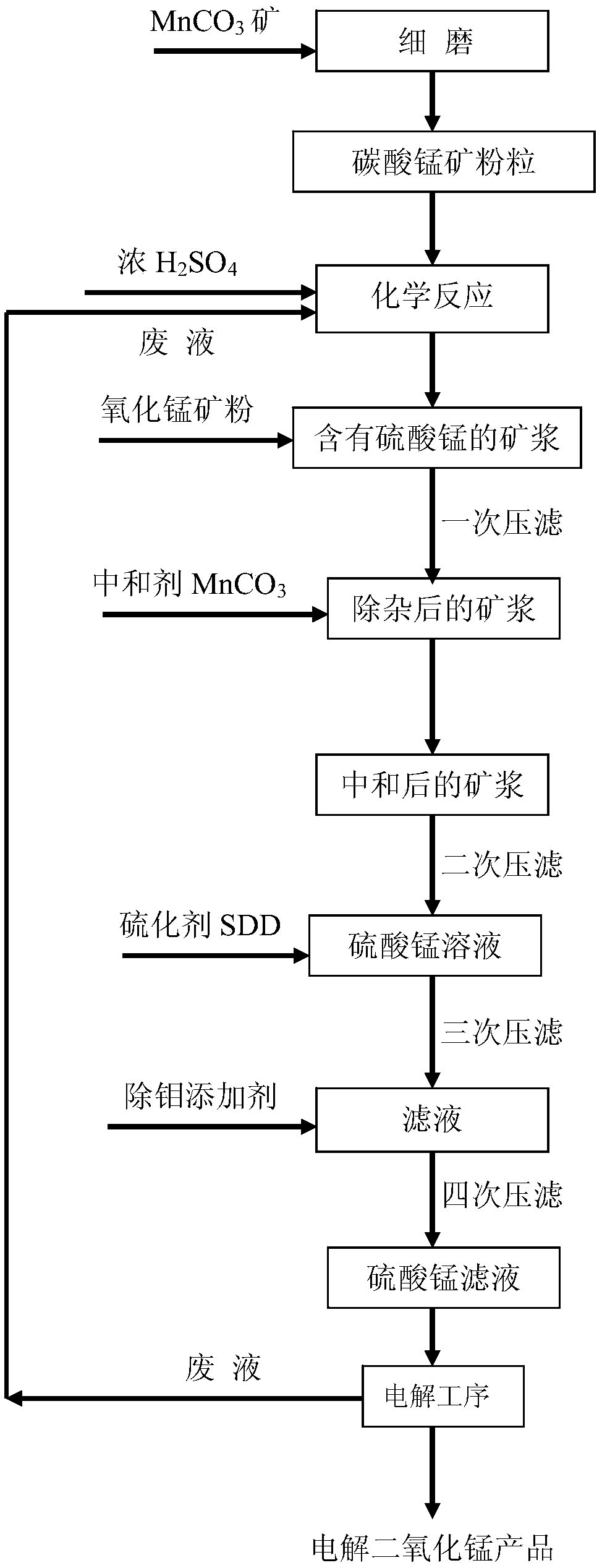

[0029] A novel neutralization process in the preparation process of electrolytic manganese dioxide, comprising the following steps:

[0030] (1) finely grinding the refined manganese carbonate ore with a manganese content of 14.5% into a manganese carbonate ore powder with a particle diameter of 0.013mm;

[0031] (2) After mixing the manganese carbonate ore powder and concentrated sulfuric acid in a ratio of 1:0.5 by weight, after heating, stirring and manganese leaching for 8 hours, obtain a slurry containing manganese sulfate with a pH value of 2.2;

[0032] (3) Add manganese oxide ore powder in the pulp containing manganese sulfate, to remove impurity potassium, iron, after carrying out press filtration once, obtain the ore pulp after impurity removal; Increase or decrease as a standard;

[0033] (4) Add neutralizer manganese content to the manganese carbonate magnetic separation tailings powder of 3.4% in the ore pulp after impurity removal, carry out neutralization react...

Embodiment 2

[0038] A novel neutralization process in the preparation process of electrolytic manganese dioxide, comprising the following steps:

[0039] (1) finely grinding the refined manganese carbonate ore with a manganese content of 14.8% into a manganese carbonate ore powder with a particle diameter of 0.0374mm;

[0040] (2) After mixing manganese carbonate ore powder and concentrated sulfuric acid in a ratio of 1:0.55 by weight, after heating, stirring and manganese leaching for 8 hours, obtain a slurry containing manganese sulfate with a pH value of 2.1;

[0041] (3) Add manganese oxide ore powder in the pulp containing manganese sulfate, to remove impurity potassium, iron, after carrying out press filtration once, obtain the ore pulp after impurity removal; Increase or decrease as a standard;

[0042] (4) Adding neutralizing agent manganese content to the manganese carbonate magnetic separation tailings powder of 3.3% in the ore pulp after impurity removal, carry out neutralizati...

Embodiment 3

[0047] A novel neutralization process in the preparation process of electrolytic manganese dioxide, comprising the following steps:

[0048] (1) finely grinding the refined manganese carbonate ore with a manganese content of 15.1% into a manganese carbonate ore powder with a particle diameter of 0.053mm;

[0049](2) After mixing the manganese carbonate ore powder and concentrated sulfuric acid in a ratio of 1:0.6 by weight, after heating, stirring and manganese leaching for 8 hours, obtain a slurry containing manganese sulfate with a pH value of 2.2;

[0050] (3) Add manganese oxide ore powder in the pulp containing manganese sulfate, to remove impurity potassium, iron, after carrying out press filtration once, obtain the ore pulp after impurity removal; Increase or decrease as a standard;

[0051] (4) Add neutralizer manganese content to the manganese carbonate magnetic separation tailings powder of 3.1% in the ore pulp after impurity removal, carry out neutralization reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com