fe-si-b-nb-cu iron-based amorphous/nanocrystalline soft magnetic alloy material and its preparation and heat treatment process

A fe-si-b-nb-cu, nanocrystalline soft magnetic technology, applied to magnetic materials, heat treatment furnaces, heat treatment equipment, etc., can solve the problem of poor vacuum conditions, narrow temperature range, and increased raw material costs, etc. problem, to achieve the effect of long time spent on solving, ensuring temperature consistency, and improving anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

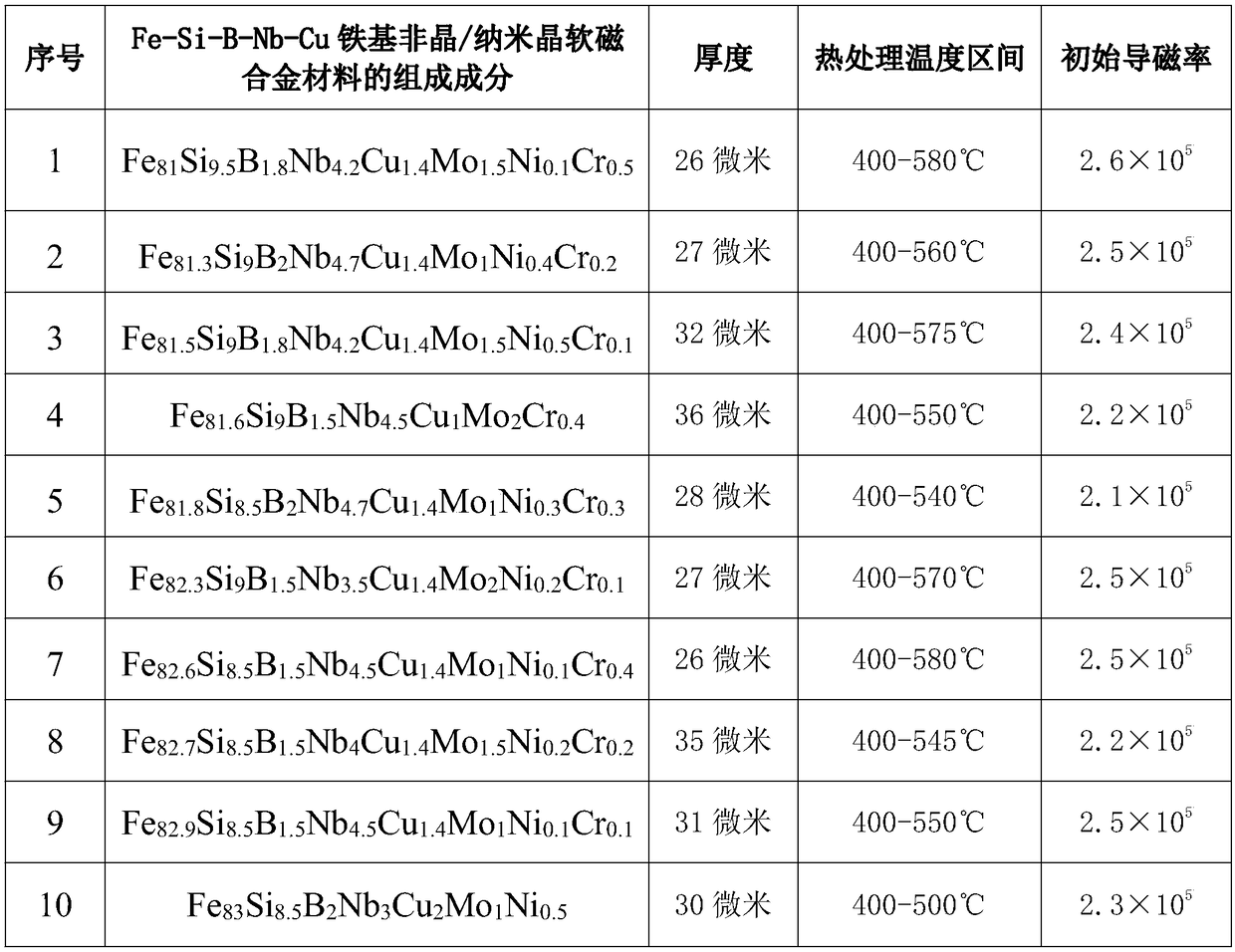

Examples

Embodiment 1

[0032] Example 1 - Preparation of a Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material and its heat treatment process: including material composition design, strip spraying and strip heat treatment process parts, specifically Proceed as follows:

[0033] 1. Material composition design

[0034] The composition of Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material is: iron Fe 81%, silicon Si 9.5%, boron B 1.8%, niobium Nb 4.2%, copper Cu 1.4% , molybdenum Mo 1.5%, nickel Ni 0.1% and chromium Cr 0.5%. Namely: Fe 81 Si 9.5 B 1.8 Nb 4.2 Cu 1.4 Mo 1.5 Ni 0.1 Cr 0.5

[0035] 2. Strip spraying

[0036] Firstly, the raw materials are prepared according to the ratio of the elements in the design, and the master alloy is smelted by non-vacuum in an intermediate frequency furnace; secondly, the master alloy is remelted and prepared into an alloy strip with a thickness of 26 microns and a width of 25mm by gravity spraying...

Embodiment 2

[0043] Example 2 - Preparation of a Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material and its heat treatment process: including material composition design, strip spraying and strip heat treatment process parts, specifically Proceed as follows:

[0044] 1. Material composition design

[0045] The composition of Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material is: iron Fe 83%, silicon Si 8.5%, boron B 2%, niobium Nb 3%, copper Cu 2% , molybdenum Mo 1% and nickel Ni 0.5%. Namely: Fe 83 Si 8.5 B 2 Nb 3 Cu 2 Mo 1 Ni 0.5

[0046] 2. Strip spraying

[0047] Firstly, the raw materials are prepared according to the proportion of the elements in the design, and the master alloy is smelted by non-vacuum in the intermediate frequency furnace; secondly, the master alloy is remelted and prepared into an alloy strip with a thickness of 31 microns and a width of 40mm by gravity spraying technology; finally, the alloy stri...

Embodiment 3

[0054] Example 3 - Preparation of a Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material and its heat treatment process: including material composition design, strip spraying and strip heat treatment process parts, specifically Proceed as follows:

[0055] 1. Material composition design

[0056] The composition of Fe-Si-B-Nb-Cu iron-based amorphous / nanocrystalline soft magnetic alloy material is: iron Fe 81.6%, silicon Si 9%, boron B 1.5%, niobium Nb 4.5%, copper Cu 1%, molybdenum Mo 2% and Chromium Cr 0.4%. Namely: Fe 81.6 Si 9 B 1.5 Nb 4.5 Cu 1 Mo 2 Cr 0.4

[0057] 2. Strip spraying

[0058] Firstly, the raw materials are prepared according to the ratio of the elements in the design, and the master alloy is smelted by non-vacuum in the intermediate frequency furnace; secondly, the master alloy is remelted and prepared into an alloy strip with a thickness of 36 microns and a width of 5mm by gravity spraying technology; finally, the alloy s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com