A kind of sintering process of neodymium iron boron

A NdFeB technology, which is applied in the field of NdFeB sintering technology, can solve the problems of product performance, magnetic performance degradation, long time-consuming secondary deflation, and fast discharge speed, so as to improve magnetic performance, avoid adverse effects, The effect of fast emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

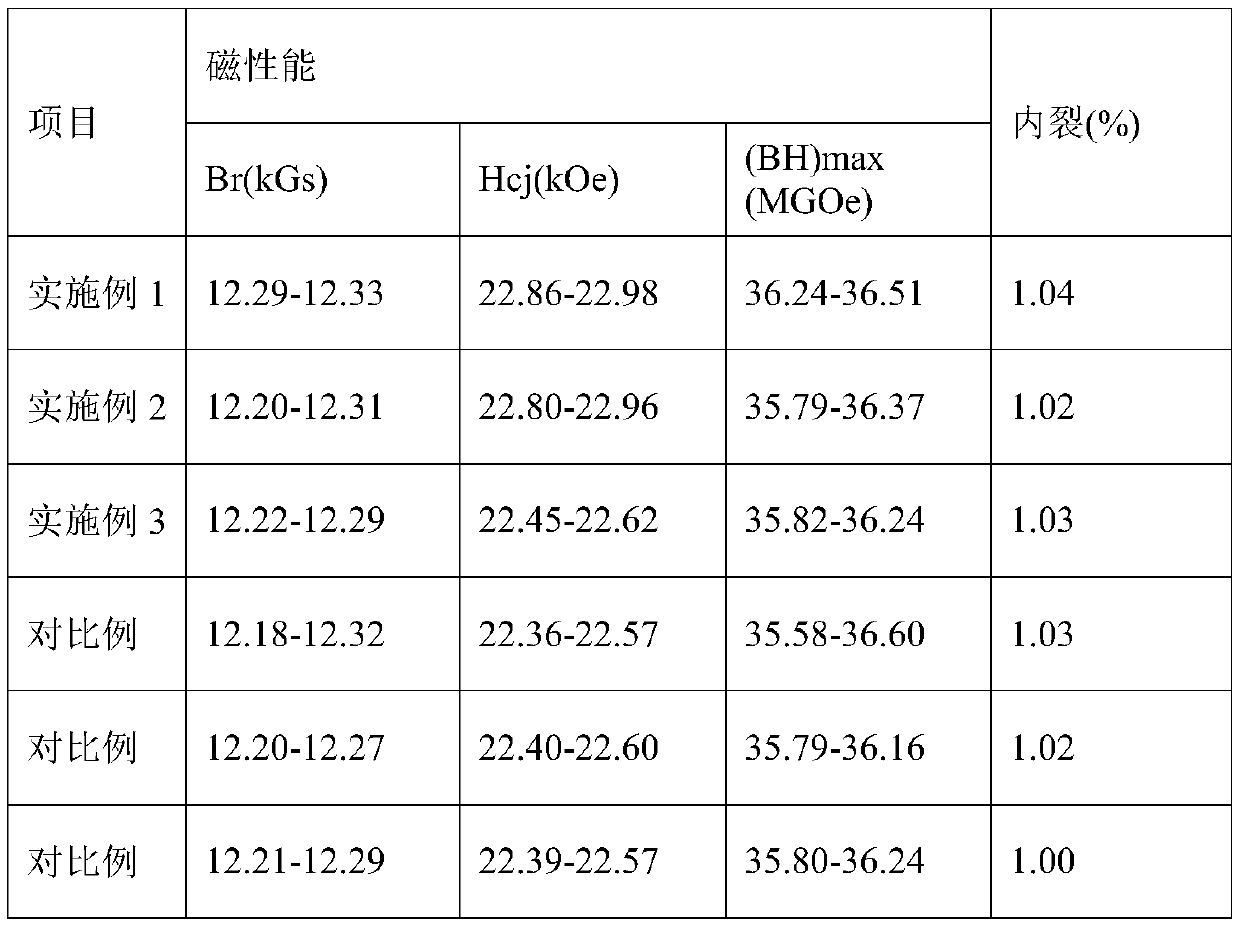

Examples

Embodiment 1

[0038] A kind of NdFeB finished product is sintered in the following steps:

[0039](1) Compacting step: Put the sintered NdFeB powder into the forming press for orientation forming and pressing to obtain the required specification blank, and perform isostatic pressing secondary molding process to increase the density of the blank, under the condition of gas protection , put the blank into the prepared high temperature resistant material model to obtain the NdFeB magnet compact;

[0040] (2) Step into the furnace: put the NdFeB magnet compact into the material holder, put the NdFeB magnet compact together with the material holder into the sintering space in the furnace, the material holder and the material The trays are staggered, leaving a gap between the trays;

[0041] (3) Decarburization step: use a vacuum pumping unit to evacuate until the air pressure in the furnace is 0.5Pa, then raise the temperature to make the temperature in the furnace reach 400°C, the heating time...

Embodiment 2

[0047] A kind of NdFeB blank product is sintered in the following steps:

[0048] (1) Compacting step: Put the sintered NdFeB powder into the forming press for orientation forming and pressing to obtain the required specification blank, and perform isostatic pressing secondary molding process to increase the density of the blank, under the condition of gas protection , put the blank into the prepared high temperature resistant material model to obtain the NdFeB magnet compact;

[0049] (2) Step into the furnace: put the NdFeB magnet compact into the material holder, put the NdFeB magnet compact together with the material holder into the sintering space in the furnace, the material holder and the material The trays are staggered, leaving a gap between the trays;

[0050] (3) Decarburization step: use a vacuum pumping unit to evacuate until the air pressure in the furnace is 0.5 Pa, then raise the temperature to make the temperature in the furnace reach 450 ° C, the heating tim...

Embodiment 3

[0056] A kind of NdFeB blank product is sintered in the following steps:

[0057] (1) Compacting step: Put the sintered NdFeB powder into the forming press for orientation forming and pressing to obtain the required specification blank, and perform isostatic pressing secondary molding process to increase the density of the blank, under the condition of gas protection , put the blank into the prepared high temperature resistant material model to obtain the NdFeB magnet compact;

[0058] (2) Step into the furnace: put the NdFeB magnet compact into the material holder, put the NdFeB magnet compact together with the material holder into the sintering space in the furnace, the material holder and the material The trays are staggered, leaving a gap between the trays;

[0059] (3) Decarburization step: use a vacuum pumping unit to evacuate until the air pressure in the furnace is 0.5Pa, then raise the temperature to make the temperature in the furnace reach 380°C, the heating time i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap