Automatic sugar pulling machine

An automatic, white machine technology, applied in the fields of confectionary, application, confectionery industry, etc., can solve the problems of poor whitening effect, unable to meet the needs of large-scale production, long whitening time, etc., and achieve convenient operation and easy promotion and use , Improve the effect of whitening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

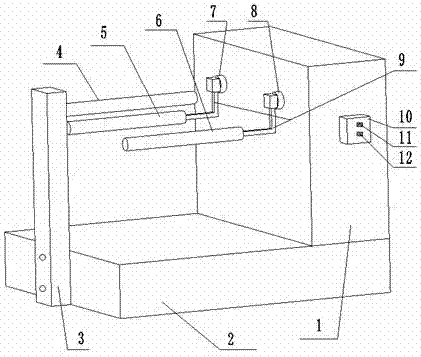

[0012] Such as figure 1 As shown, a kind of automatic whitening machine for candy according to the present invention includes an organic base 2, a support arm 3 and a motor box 1, and the support arm 3 and the motor box 1 are arranged in a vertical state respectively. On the body base 2, a fixed pull rod 4 is arranged above the storage platform of the body base 2, and the fixed pull rod 4 is fixed on the upper part of the support arm 3, and the motor box 1 is provided with a first The rotating shaft 7 and the second rotating shaft 8, the first rotating shaft 7 and the second rotating shaft 8 are respectively connected with the first pulling rod 5 and the second pulling rod 6 through the rotating arm 9, and the motor box 1 is provided with a device for driving the first A variable frequency motor that rotates the rotating shaft 7 and the second rotating shaft 8, under the action of the variable frequency motor, drives the first pull rod 5 and the second pull rod 6 to rotate syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com