Method for processing portable telescopic tube seat

A processing method and telescopic tube technology, applied to chairs, folding chairs, detachable chairs, etc., can solve the problems of large size and inconvenient portability, and achieve the effects of small size, material saving, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

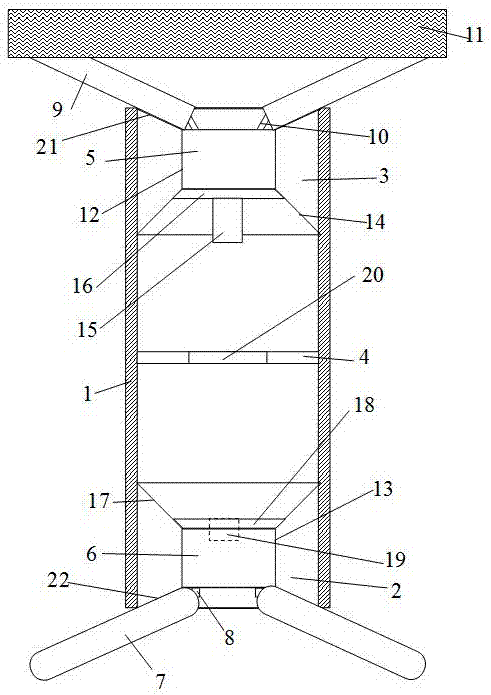

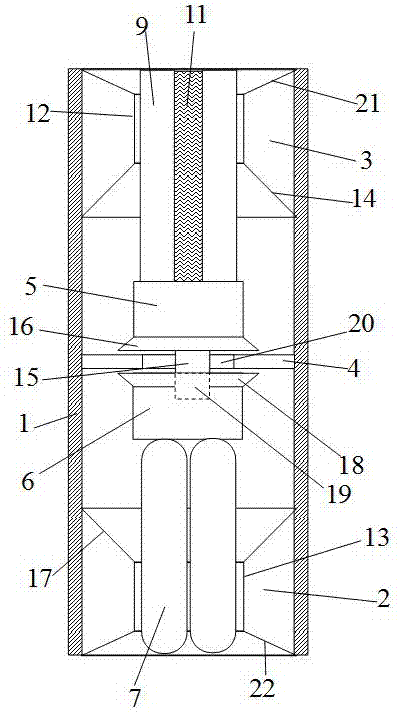

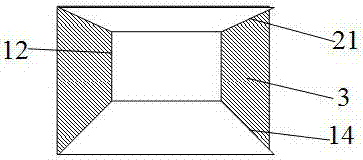

[0023] Such as Figure 1-5 As shown, the present invention includes a lightweight high-strength barrel 1, a bottom support and a fixed ring 2, a top support and a fixed ring 3, a middle reinforcement and a limit plate 4, an upper seat support and a fixed shaft 5, and a lower leg support and a fixed shaft 6 , retractable support leg 7, retractable pull rod with spring support leg 8, retractable support seat 9, retractable pull rod with spring support seat 10, wear-resistant cloth 11, upper seat fixing screw 12, lower support leg fixing screw 13, upper Seat limiting cone 14, fixed bolt 15 when stowed, upper seat limiting cone 16 when unfolding, lower leg limiting cone 17, lower leg limiting vertebral body 18 when unfolding, fixing screw 19 when retracting, The middle limit opening 20 when packing up, the upper seat limit and support cone opening 21 and the lower leg limit and support cone opening 22 when unfolding.

[0024] A processing method for a portable telescopic tube sea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap