Automatic drainage type grinding equipment for biological laboratory

A laboratory and equipment technology, applied in the field of automatic drainage type biological laboratory grinding equipment, can solve the problems of low experimental efficiency, low degree of automation, affecting experimental data and experimental efficiency, etc., to improve experimental efficiency and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

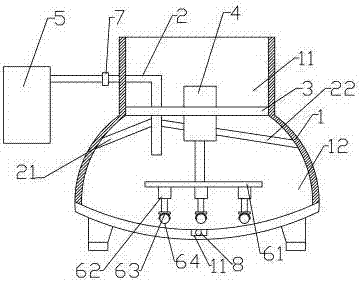

[0012] Combine below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0013] An automatic drainage type biological laboratory grinding equipment, including a grinding kettle body 1 and a drainage tube 2, the drainage tube is connected to the grinding kettle body 1, and the inside of the grinding kettle body 1 is provided with a A partition 3 forming an upper chamber 11 and a lower chamber 12, the partition 3 is provided with a lifting device 4 whose telescoping end is located in the lower chamber 12, and one side of the lifting device 4 is provided with a drainage tube 2 passing through the partition , the outer end of the drainage tube 2 is connected with the distillation device 5, the distillation device 5 is used to supply distilled water, and the other end is provided with a first shunt pipe 21 and a second shunt pipe 22 located in the lower cavity 12, the first shunt pipe 22 The outlet ends of the shunt pipe 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com