Smashing device for ore processing and with function of continuous shaking blanking

A pulverizing device and ore technology, applied in grain processing and other directions, can solve the problems of inapplicable ore crushing, incomplete ore pulverization, affecting the use of ore, etc., so as to improve the pulverization effect, reduce energy consumption, and reduce the amount of ore to be extruded. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

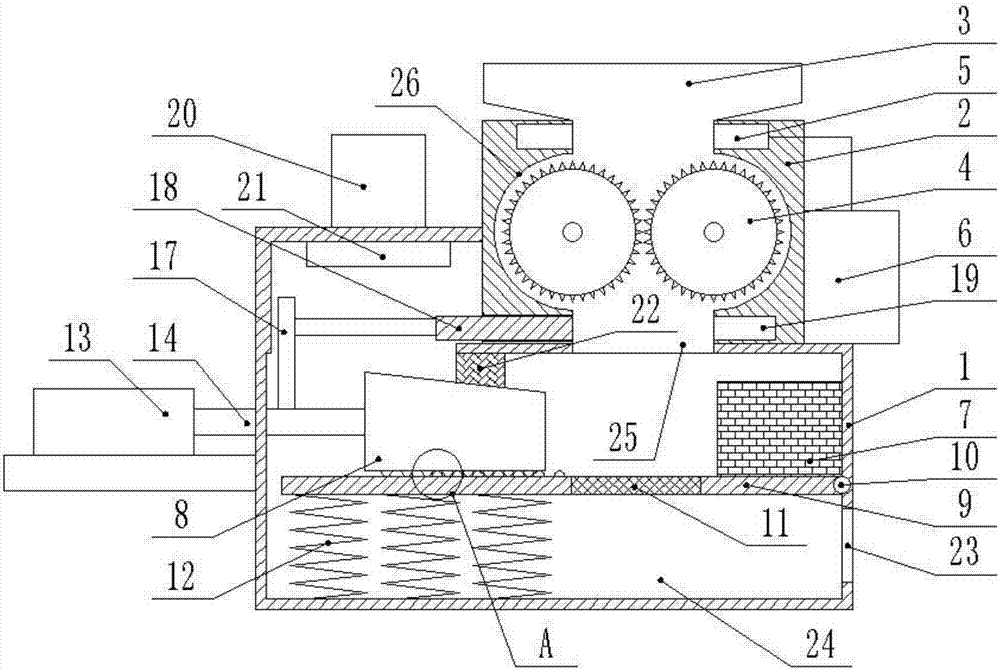

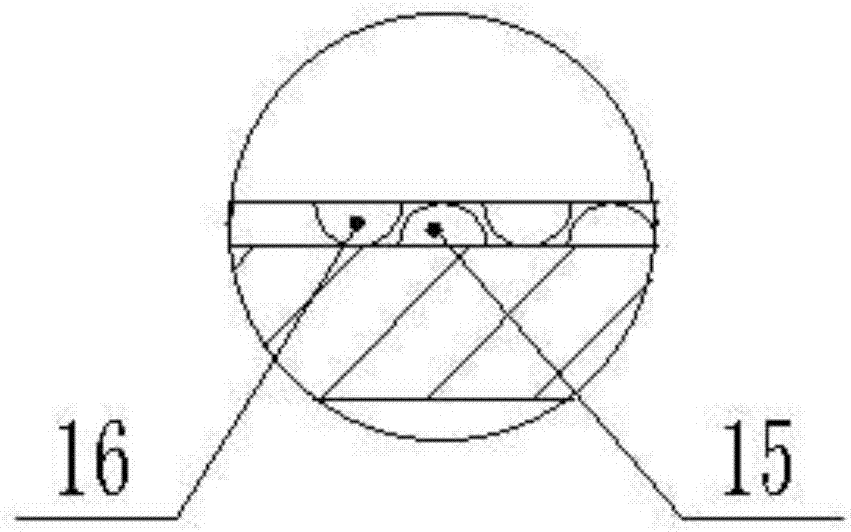

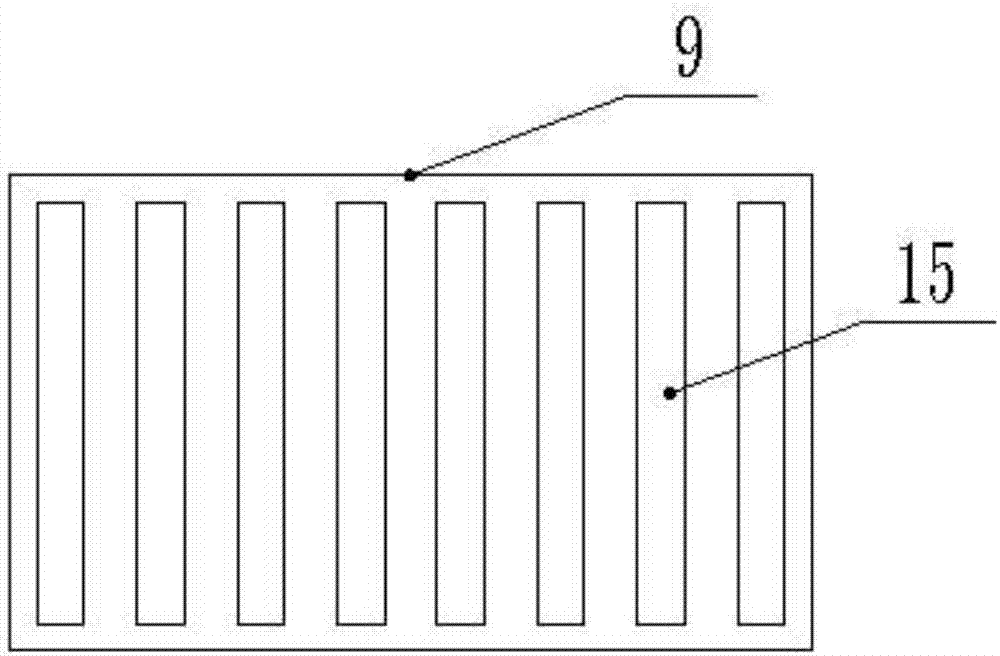

[0018] Please refer to the figure, in the embodiment of the present invention, a crushing device for ore processing with continuous shaking and blanking includes a casing 1, a crushing box 2, a feed hopper 3 and a hydraulic cylinder 13; the crushing box 2 is fixed on the casing 1, the feed hopper 3 is connected to the top of the crushing box 2, and two crushing rollers 4 that are squeezed and engaged with each other are installed in the crushing box 2, and a crushing groove 26 is arranged in the crushing box 2 corresponding to the crushing rollers 4. The groove 26 is an arc groove, the central axis of which coincides with the central axis of the corresponding crushing roller 4, so that the incoming ore can be squeezed and crushed between the two crushing rollers 4, and the lower end of the crushing groove 26 is connected with a discharge port 25, the blanking port 25 leads into the housing 1; a water spray pipe 5 is arranged above the crushing roller 4 in the crushing box 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com