A construction method for large-section intersecting circular tubular steel members

A construction method and technology for steel components, applied in the field of steel component production, can solve the problems of large consumption of materials, low production efficiency, and difficulty in guaranteeing cutting quality and precision, and achieve reliable technology, reduced manufacturing costs, and improved construction accuracy and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

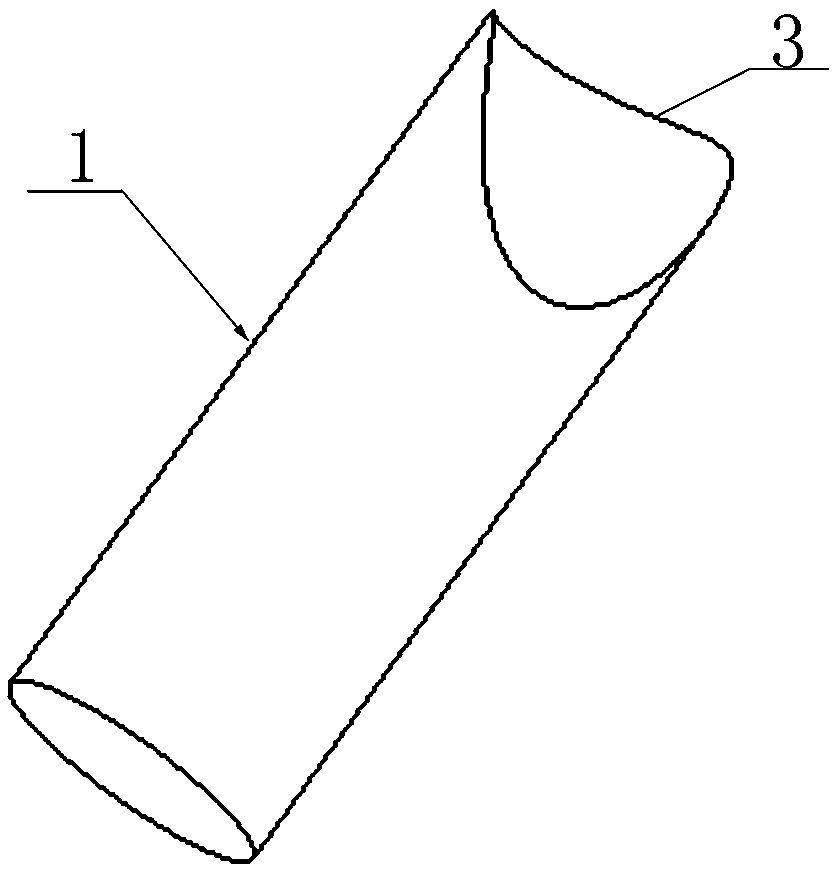

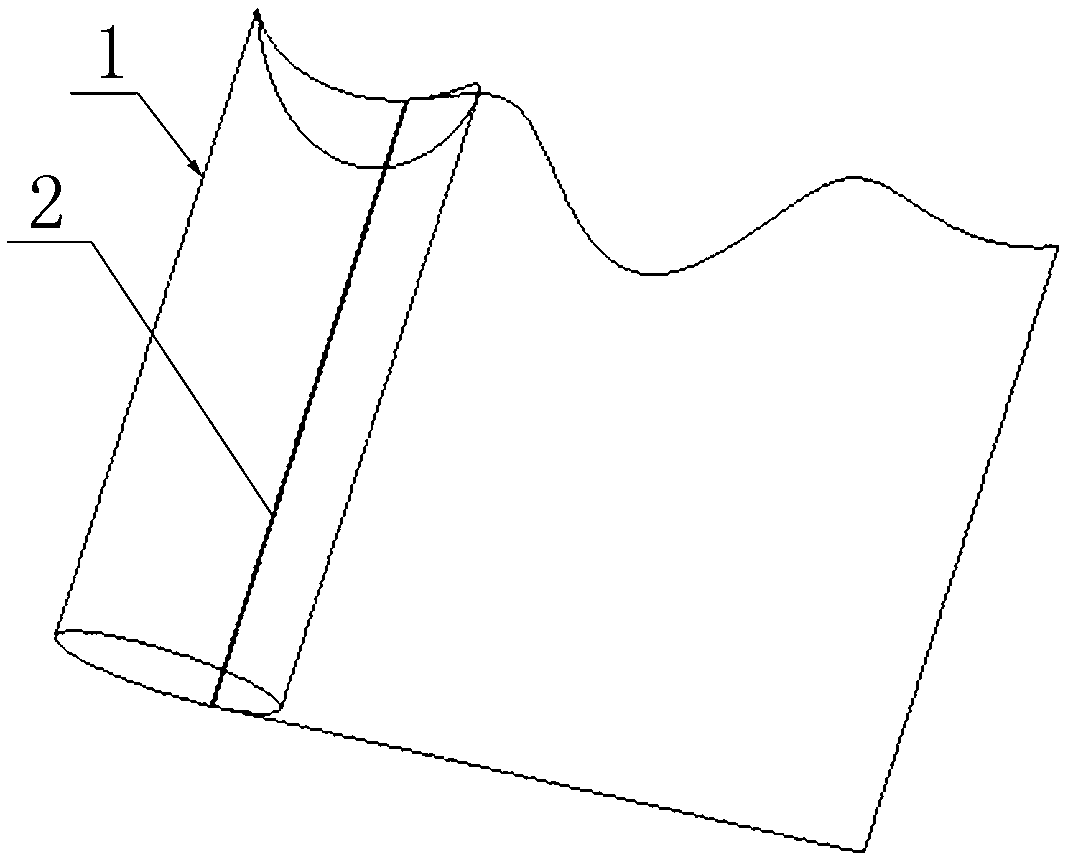

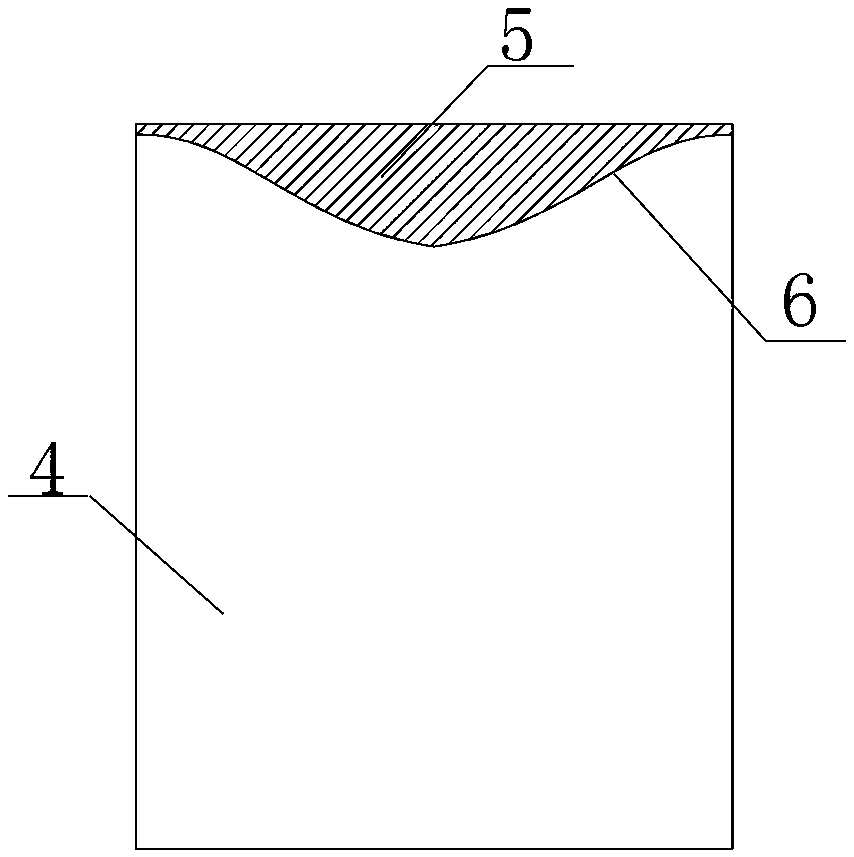

[0040] This embodiment is a construction method for large cross-section intersecting circular tubular steel members. First, three-dimensional full-real modeling of circular tubular steel members is carried out, and then lofting is carried out, information is exported, cutting programs are compiled, and materials are cut using a fully automatic cutting machine tool. Then the steel plate is placed on the plate rolling machine, and the improved process is used for rolling, and finally the longitudinal seam welding of the round pipe steel member is carried out and the allowance is cut.

[0041] The construction method of the large cross-section intersecting circular tubular steel member includes the following steps.

[0042] Step 1: According to the structural drawings, first use Creo software to model the three-dimensional full-true model 1 of the round tubular steel member; establish a 1:1 full-real three-dimensional full-real model 1. In order to improve the lofting accuracy, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com