Anti-explosion polishing unit

A polishing machine and unit technology, applied in the field of optical units, can solve the problems of dust explosion, harm to health, mass death and injury, etc., and achieve the effect of avoiding dust explosion, preventing dust explosion and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

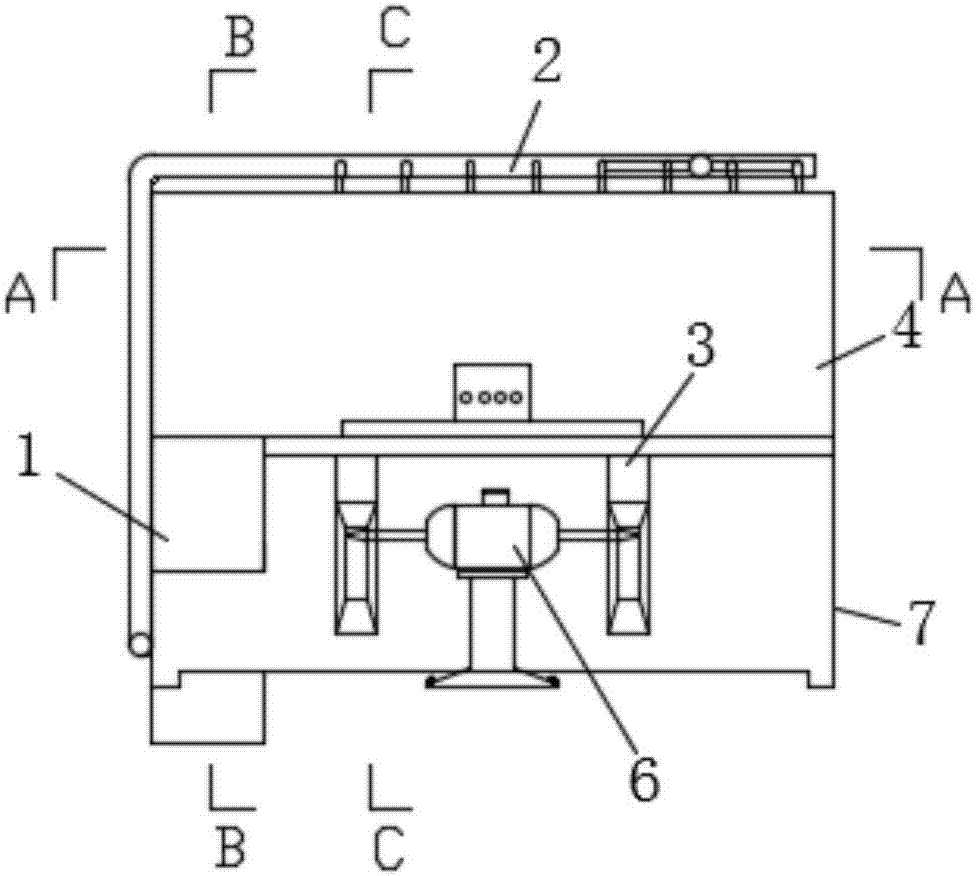

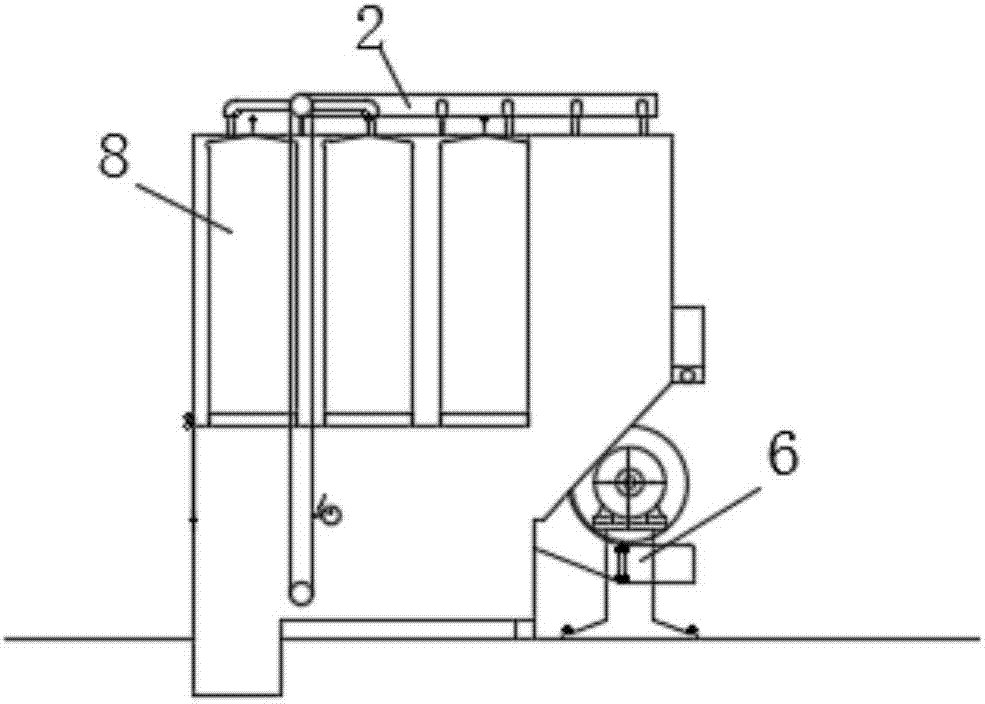

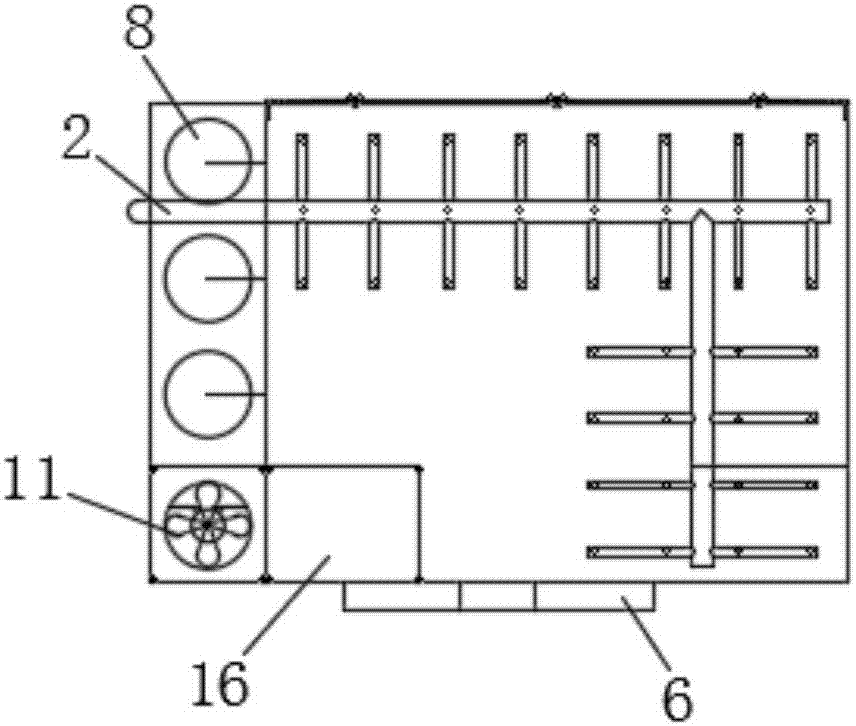

[0028] see Figure 1-6 , the present invention provides a technical solution: an explosion-proof polishing unit, including a polishing unit main body 7, the polishing unit main body 7 is composed of a water pump 1, a polishing machine 6, an exhaust fan 11 and a housing 4, the housing 4 One side is provided with a dust suction port 3, and the inside of the dust suction port 3 is fixedly installed with a primary spray device 10 in the housing 4, and the top of the primary spray device 10 is connected with an inner spray pipe 5, polished The unit main body 7 is provided with a second spray chamber 19, and the second spray chamber 19 is provided with a secondary spray device 9, and the secondary spray device 9 includes an air channel 14 and a guide cover 18, and the guide The cover 18 is fixedly arranged inside the air passage 14, the top of the housing 4 is fixedly equipped with a spray pipe 2, and the bottom of the air passage 14 is fixedly arranged with a circulation pool 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com