Meat cutter with slicer cleaning function

A meat cutting machine and functional technology, applied in metal processing and other directions, can solve the problems of sticking meat scraps on the blade and affecting operation, and achieve the effect of stable transmission and avoidance of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

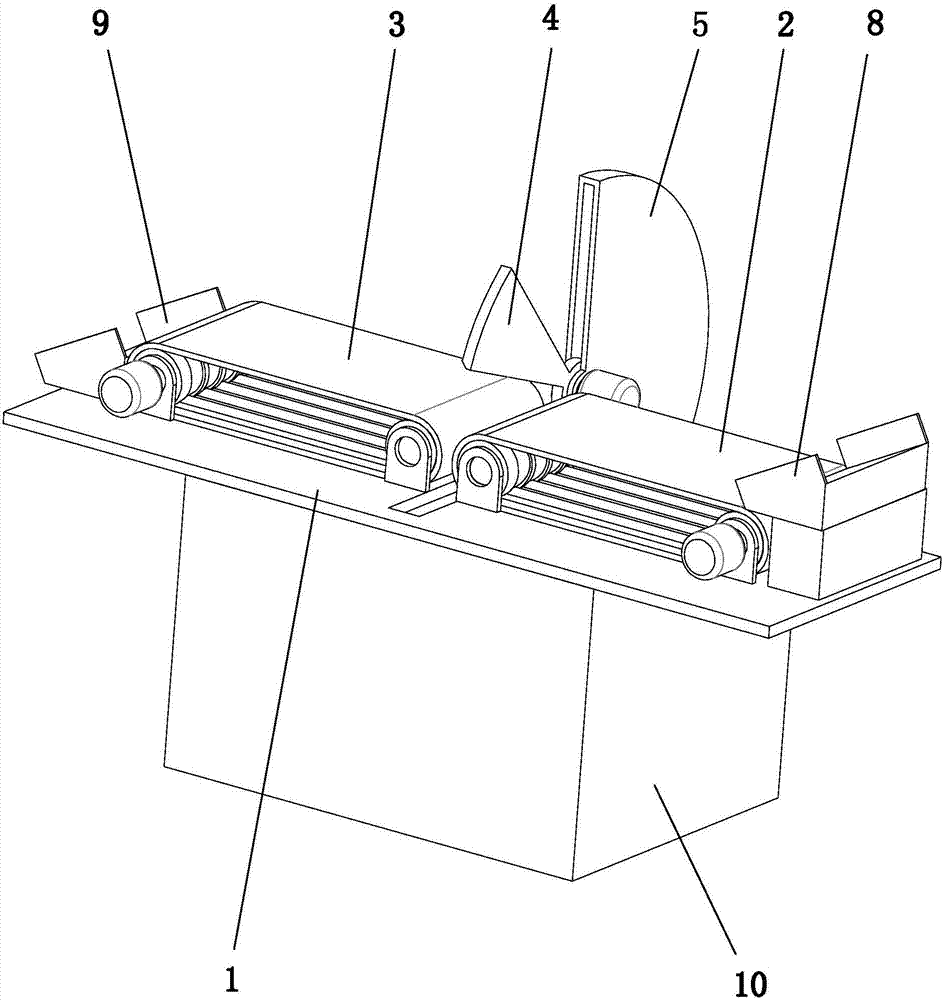

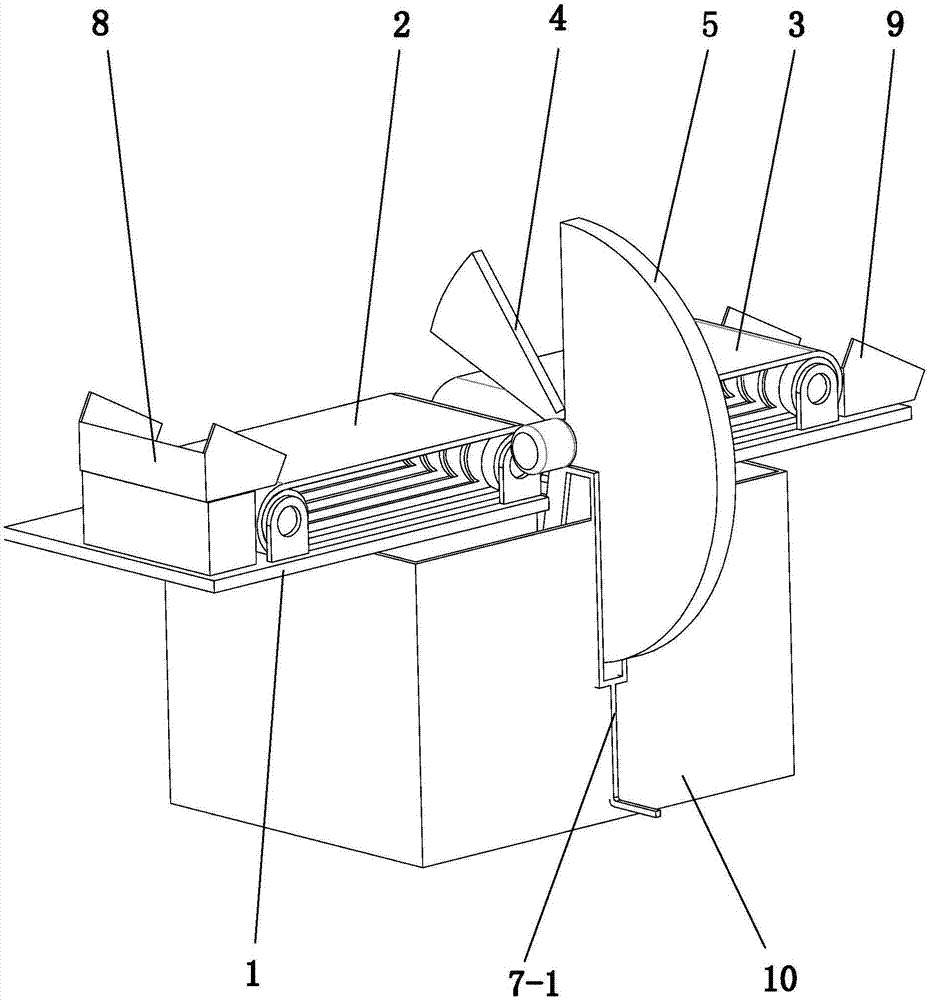

[0022] A meat cutting machine with a knife cleaning function described in this implementation includes a workbench 1 and a material conveying device. The material conveying device includes a feed belt 2 and a discharge belt 3 arranged in series on the workbench 1. The feed belt 2 The front end of the feed port 8 is set, and the tail end of the discharge belt 3 is set with a discharge port 9, as attached figure 1 shown.

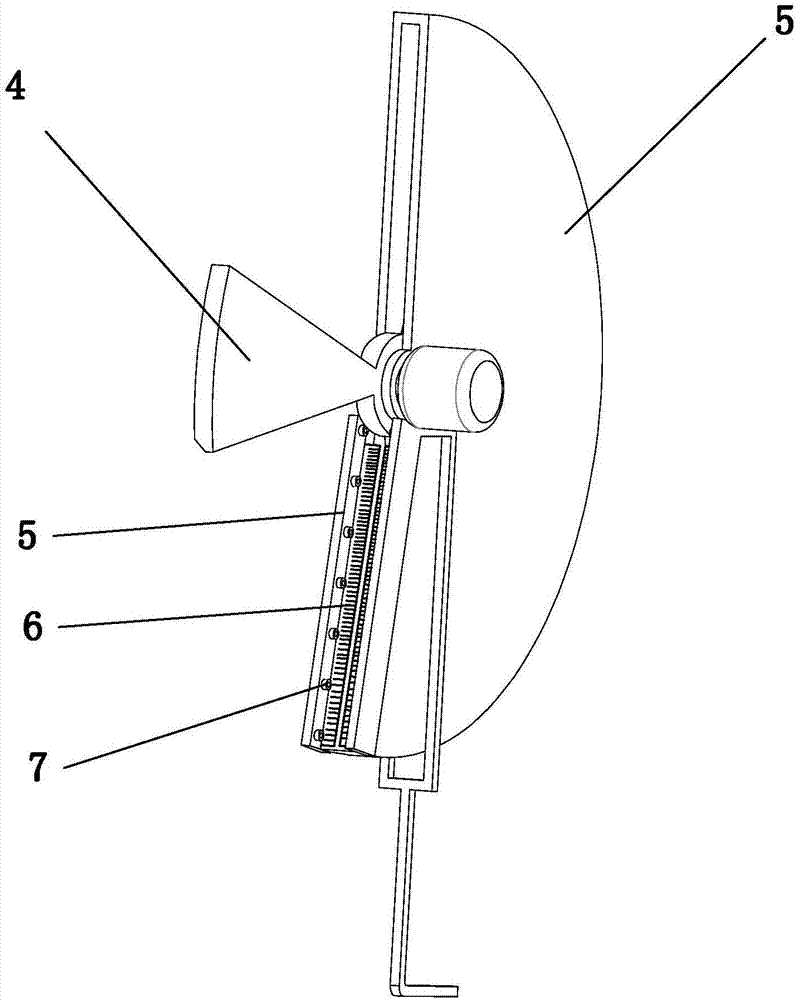

[0023] The meat cutter adopts a leaf fan-shaped cutter 4 with three fan blades, and the cutter 4 is hingedly arranged in the arc-shaped knife groove 5 and is driven by a motor. The cutting device formed by the cutter 4 and the knife groove 5 is arranged perpendicular to the conveying direction of the material conveying device. image 3 shown.

[0024] The lower notch of the knife groove 5 is a stepped struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com