Electromagnetic heating structure

A heating structure and electromagnetic technology, applied in the direction of induction heating, induction heating devices, etc., can solve the problems of affecting the heating effect, low thermal efficiency, short life, etc., and achieve the effect of improving the heating effect, wide application range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

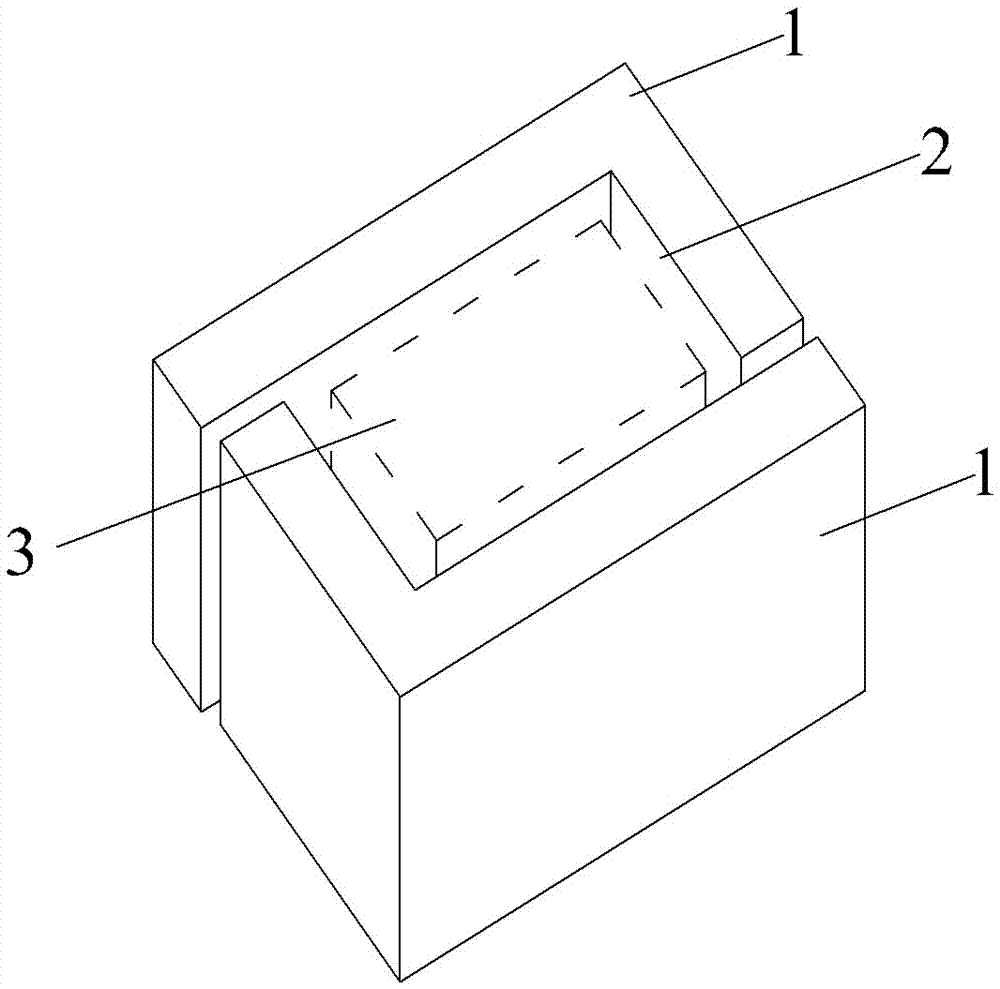

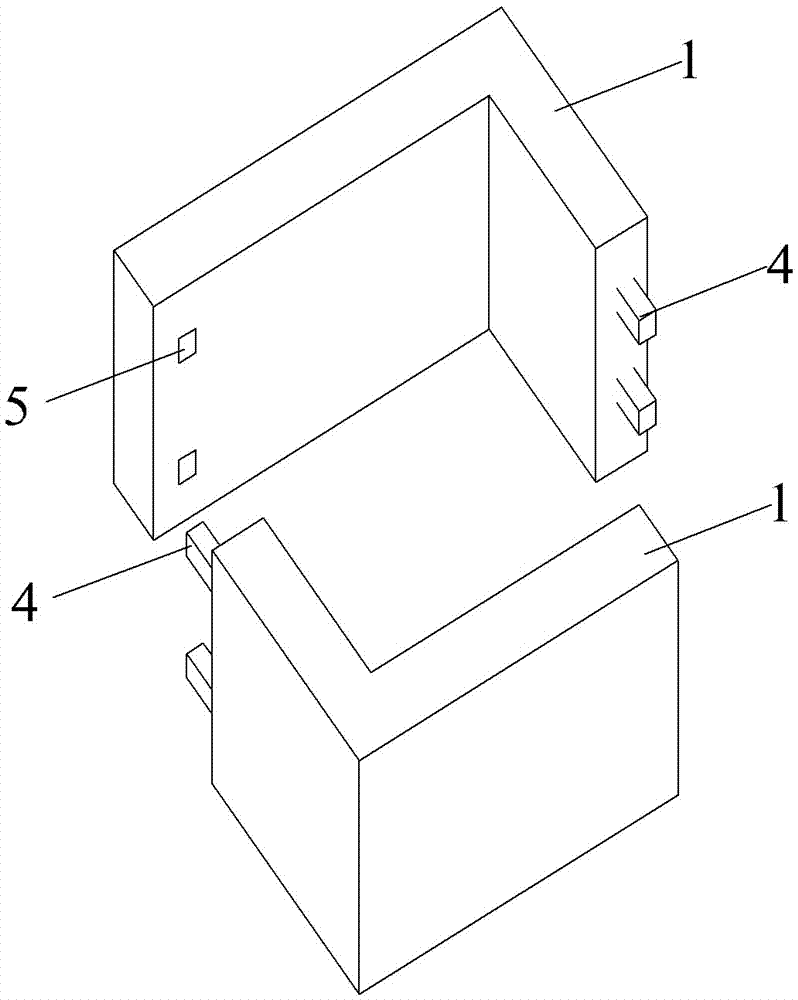

[0012] Such as figure 1 , figure 2 As shown, the present invention includes a housing and an electromagnetic induction coil. The housing is composed of two L-shaped heating bodies 1, the electromagnetic induction coil is arranged in the heating body 1, and the two heating bodies 1 form a Hafur-style rectangular structure and A through-hole cavity 2 is formed, and the heated object 3 is wrapped in the through-hole cavity 2 through the heating body 1, and the surrounding surfaces of the heated object 3 are wrapped, effectively forming a closed magnetic field, and improving the heating effect on the heated object. Wide range, especially suitable for flat twin-screw plastic mechanical heating, with high thermal efficiency, low energy consumption and long service life.

[0013] A heat conduction layer is provided between the heating body 1 and the electromagnetic induction coil. The material of the heat conduction layer is nano-ceramic material. The side ends are provided with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com