Automobile acoustic part roof shared cooling jig

A technology for acoustic components and automobiles, applied in the field of mechanical structures, can solve problems such as difficult recycling of FRP and increase production costs, and achieve the effects of reducing labor intensity, reducing production costs, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

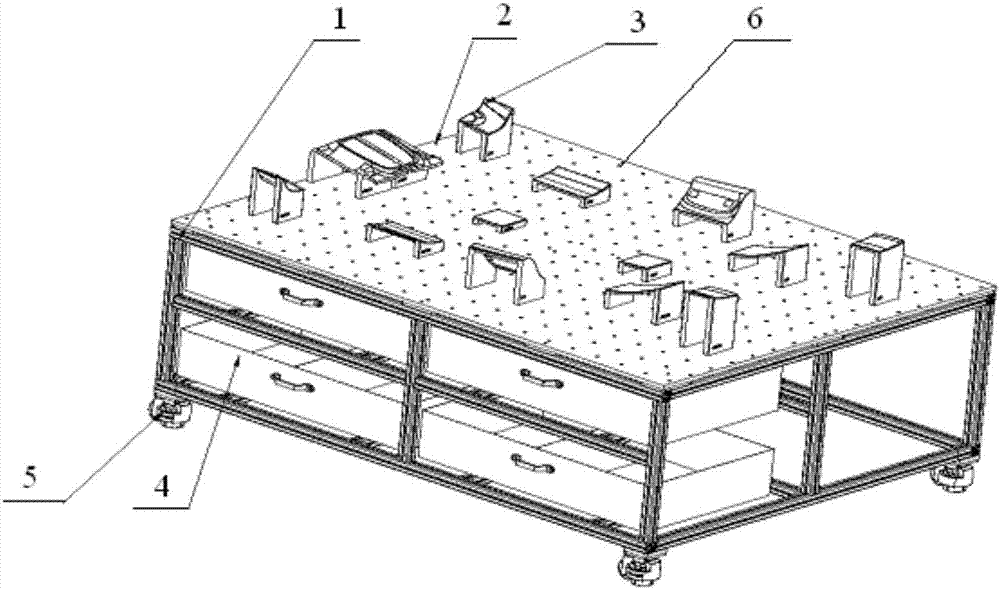

[0013] like figure 1 As shown, the shared cooling fixture for the roof of the automotive acoustic components includes a frame 1, a panel 2, a product profile 3, a drawer 4 and a moving device 5; a panel 2 is arranged above the frame 1, and several drawers can be placed in the frame 1 4. Several moving devices 5 are provided at the bottom of the frame 1; a product profile 3 that matches the product surface is provided on the panel 2.

[0014] The frame 1 is an aluminum profile frame, including an aluminum profile frame made of several aluminum profiles. The aluminum profile frame is divided into several compartments by the aluminum profiles, and a drawer 4 can be placed in each compartment.

[0015] The panel 2 is a birch board, and the birch board is evenly divided into several positioning holes 6, and the birch board is also provided with coordinates.

[0016] The product profiles 3 are 3D printed into several profiles that match the product surface.

[0017] The product pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com