Electrohydrodynamics high-resolution ink jet printing control method

An inkjet printing and body dynamics technology, applied in printing and other directions, can solve problems such as difficulty meeting real-time requirements, taking a long time, and affecting the resolution of electrohydrodynamic inkjet printing patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

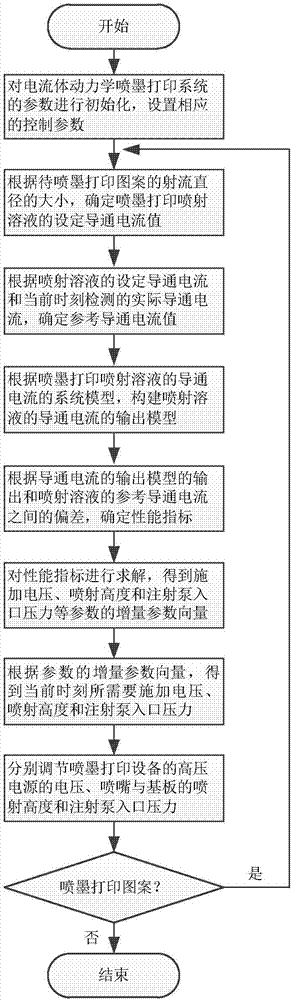

[0059] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

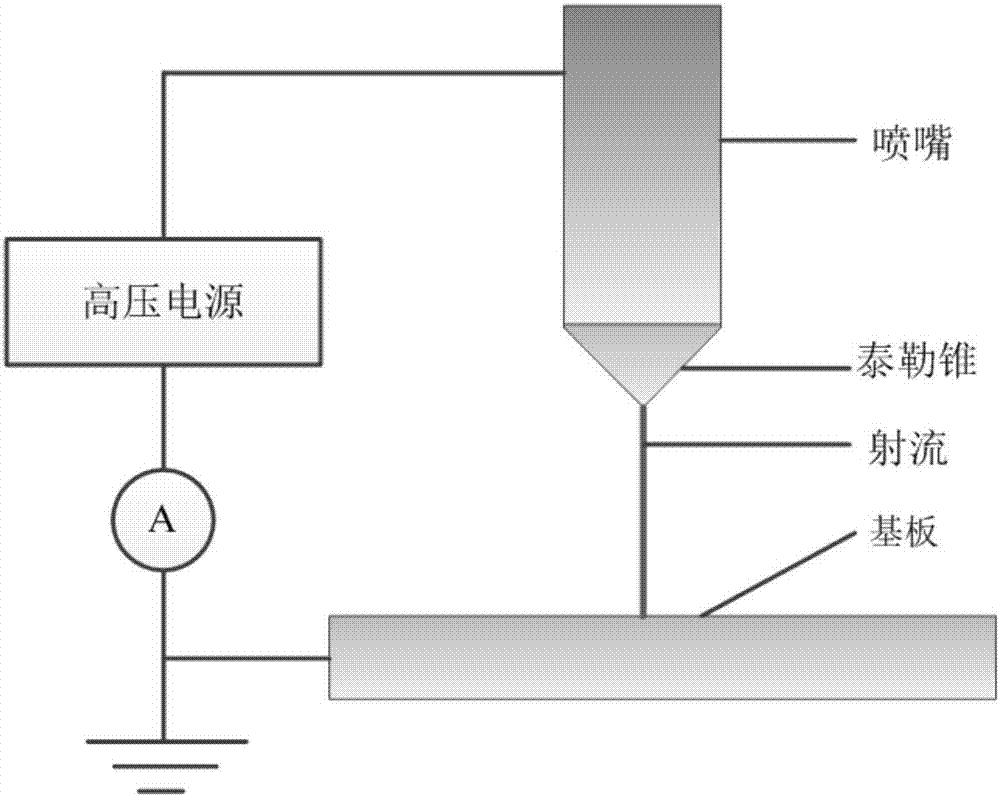

[0060] A control method for electrohydrodynamic high-resolution inkjet printing, which includes multi-physical field parameter coupling model modeling of electrohydrodynamic inkjet printing and a control method for real-time high-resolution inkjet printing.

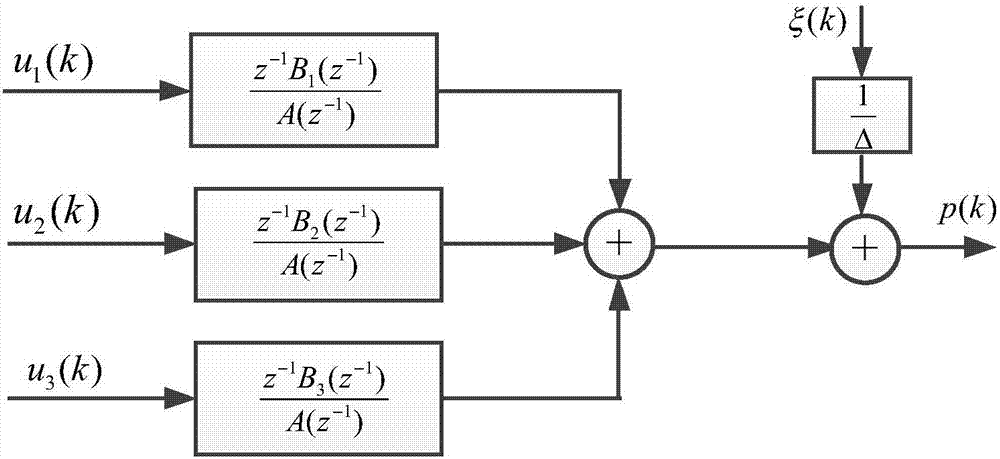

[0061] The multi-physics parameter coupling model modeling of electrohydrodynamic inkjet printing includes the modeling of the multi-physics field parameter coupling model of the on-current of the electrohydrodynamic jet solution and the construction of the electrohydrodynamic jet diameter and the on-current of the jet solution The mapping relationship between the two aspects.

[0062] The modeling of the conduction current multi-physics field parameter coupling model of electrohydrodynamic jetting solution includes the following steps:

[0063] (1) Determine the order n of the applied voltage parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com