Fast packaging operation method for PCBs

A PCB board, fast technology, applied in packaging, packaging under vacuum/special atmosphere, etc., can solve the problems of low work efficiency, unreasonable design of work links, and unsmooth work flow of employees, so as to reduce the labor intensity of workers and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

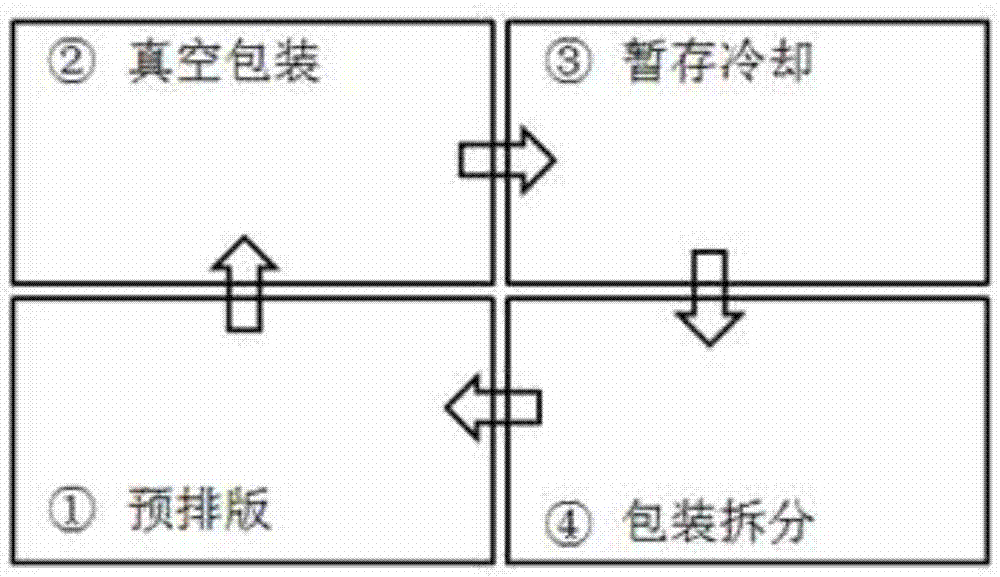

[0018] refer to figure 1 , a quick packaging operation method, the specific steps are as follows:

[0019] (1) Arrange PCB boards and corresponding auxiliary materials in the pre-layout ① area according to the quantity required by the customer;

[0020] (2) Then press the packaging start button, and the vacuum packaging auxiliary conveying platform will automatically transport the chassis (aluminum board) equipped with PCB boards in the pre-typesetting area ① to the vacuum packaging area ② for vacuum packaging operations;

[0021] (3) After the vacuum packaging operation is completed, the mechanical handle in the temporary storage cooling ③ area is automatically activated, and the chassis in the vacuum packaging ② area is pulled to the temporary storage cooling ③ area for cooling, and then transferred to the packaging split ④ area for packaging splitting ;

[0022] (4) After the package is disassembled, move the chassis horizontally to the pre-composition ① area to form a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com