Crane anti-swing control method based on frequency converter and frequency converter

A control method and frequency converter technology, applied in frequency converter-based crane anti-sway control, frequency converter field, can solve the problems of increasing fault points, increasing cost, increasing cabinet space, etc., achieving simple electrical design, fewer fault points, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

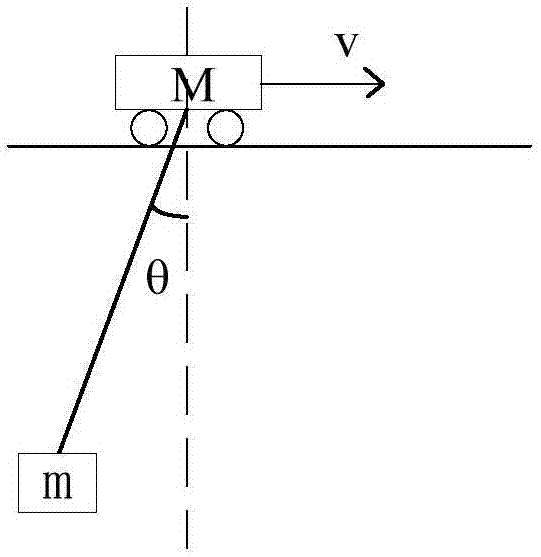

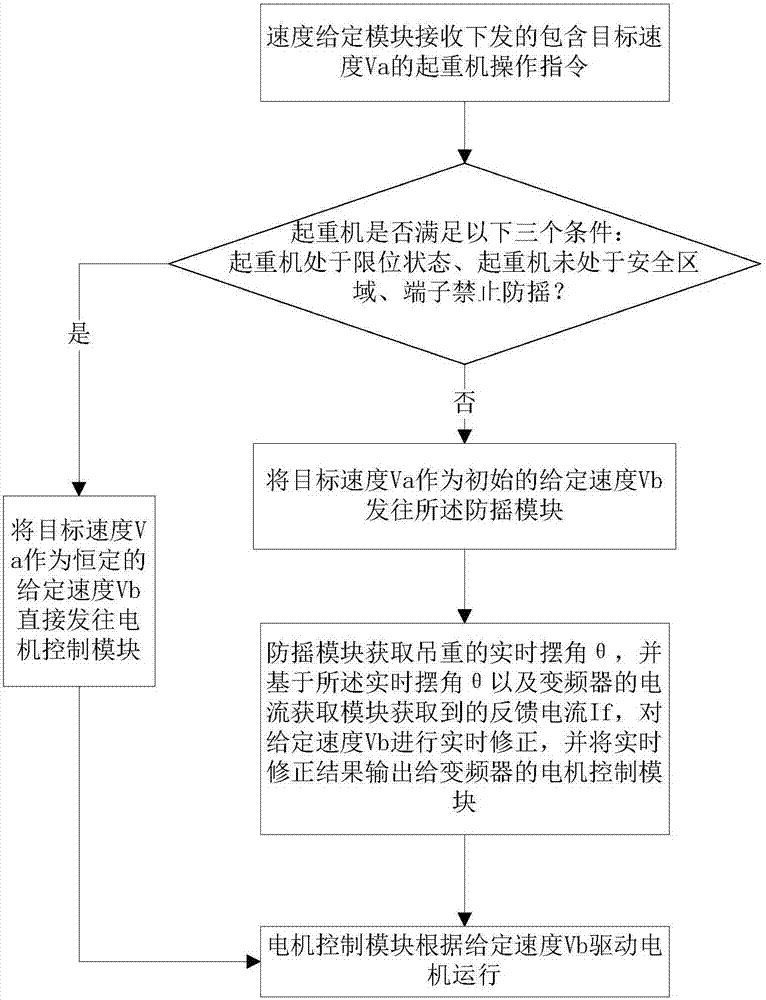

[0053] This embodiment discloses a crane anti-sway control method based on a frequency converter, and the method mainly includes:

[0054] S100. The speed given module of the frequency converter receives the issued crane operation instruction. The crane operation instruction includes the target speed Va. For safety considerations, it is necessary to judge whether it is suitable for anti-swaying. Therefore, the speed given module receives When it comes to the crane operation command, first judge whether the crane meets the following three conditions: the crane is in the limit state, the crane is not in the safe area, and the terminal is prohibited from anti-swaying. If so, the target speed Va is directly sent as the constant given speed Vb. to the motor control module, so that the motor control module always drives the motor according to the initial given speed Vb; otherwise, the target speed Va is sent to the anti-sway module as the initial given speed Vb.

[0055] S200. The a...

Embodiment 2

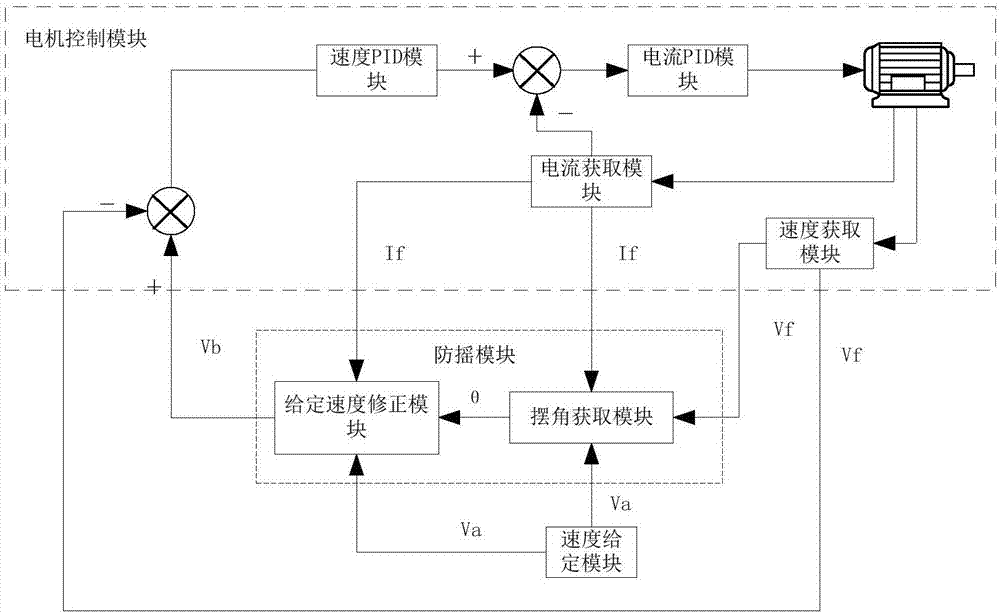

[0072] Based on the same inventive concept, this embodiment discloses a frequency converter applied to a crane, the frequency converter includes:

[0073] The speed given module is used to receive the issued crane operation instruction, the crane operation instruction includes the target speed Va, and judges whether the crane meets the following three conditions: the crane is in the limit state, the crane is not in the safe area, and the terminal is prohibited from shaking , if yes, send the target speed Va directly to the motor control module as a constant given speed Vb, so that the motor control module always drives the motor to run according to the initial given speed Vb, otherwise, take the target speed Va as the initial given speed The constant speed Vb is sent to the anti-sway module.

[0074] The anti-sway module is used to obtain the real-time swing angle θ of the hoisting weight, and based on the real-time swing angle θ and the feedback current If obtained by the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com