Pre-coating cleaning equipment for optical lens

A technology for cleaning equipment and optical lenses, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc. It can solve the problem of damage to the surface of the lens, and achieve the requirements of mild cleaning method, controllable conditions, and high-precision coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

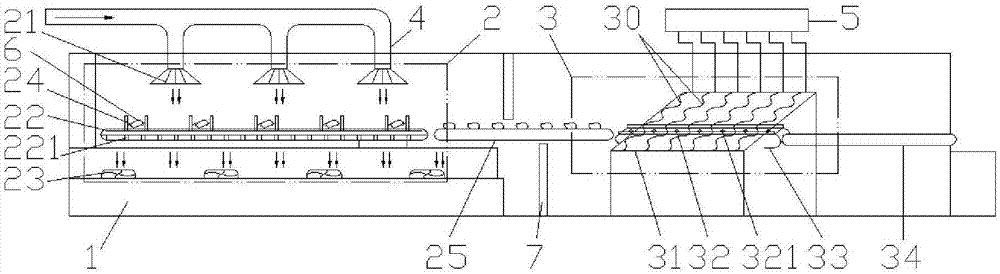

[0016] In order to more clearly illustrate the technical solutions in the embodiments of the present application or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art, and the drawings in the following description are only the application For some embodiments described in , those skilled in the art can also obtain other drawings based on these drawings without creative work.

[0017] Such as figure 1 , a kind of pre-coating cleaning equipment for optical lenses, including a horizontally placed body 1, a dust removal device 2 and a washing device 3 located inside the body 1, and an air source pipeline 4 and a cleaning liquid pool 5 outside the body 1 , the dust removal device 2 sequentially includes a blowing port 21, a first conveyor belt 22, and a suction fan 23 from top to bottom, and the first conveyor belt 22 has a ventilation hole 221. There are several mirror holders 24 on the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com