Uplift pile with upper straight rod and lower screw suitable for seasonal frozen soil regions and construction method thereof

A technology for uplift piles and permafrost areas, applied in sheet pile walls, foundation structure engineering, protection devices, etc., can solve problems such as uneconomical, reduced shear strength, and reduced bearing capacity of uplift piles, so as to ensure construction quality , The effect of improving the pull-out bearing capacity and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

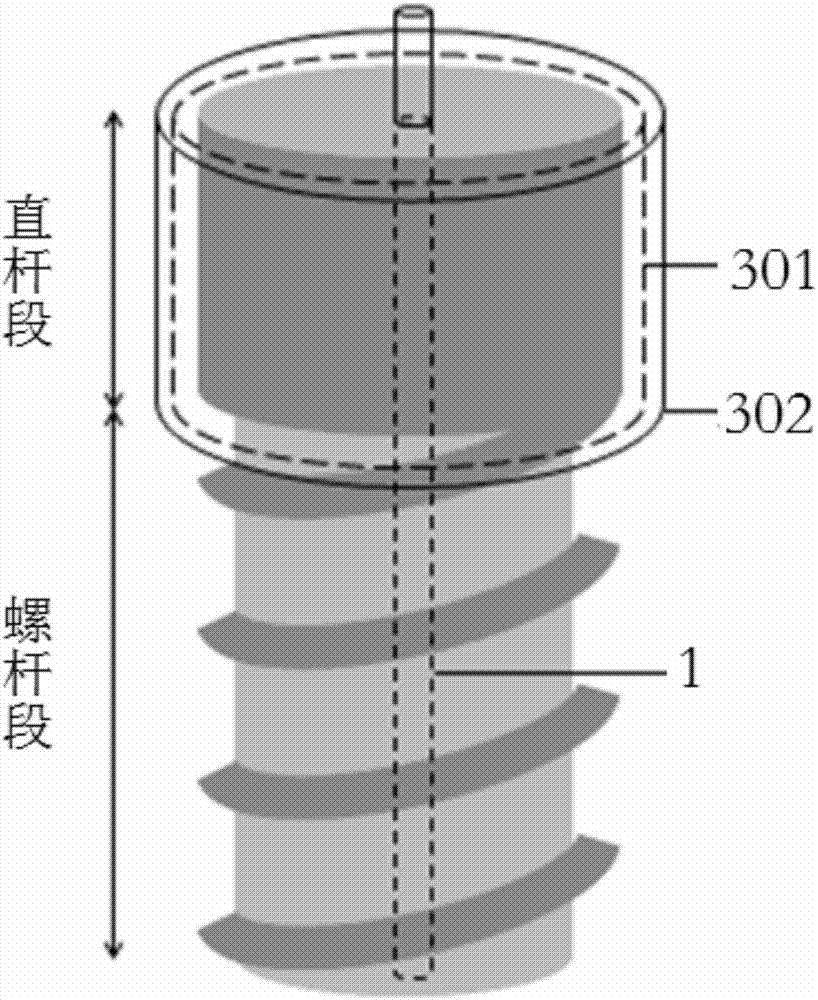

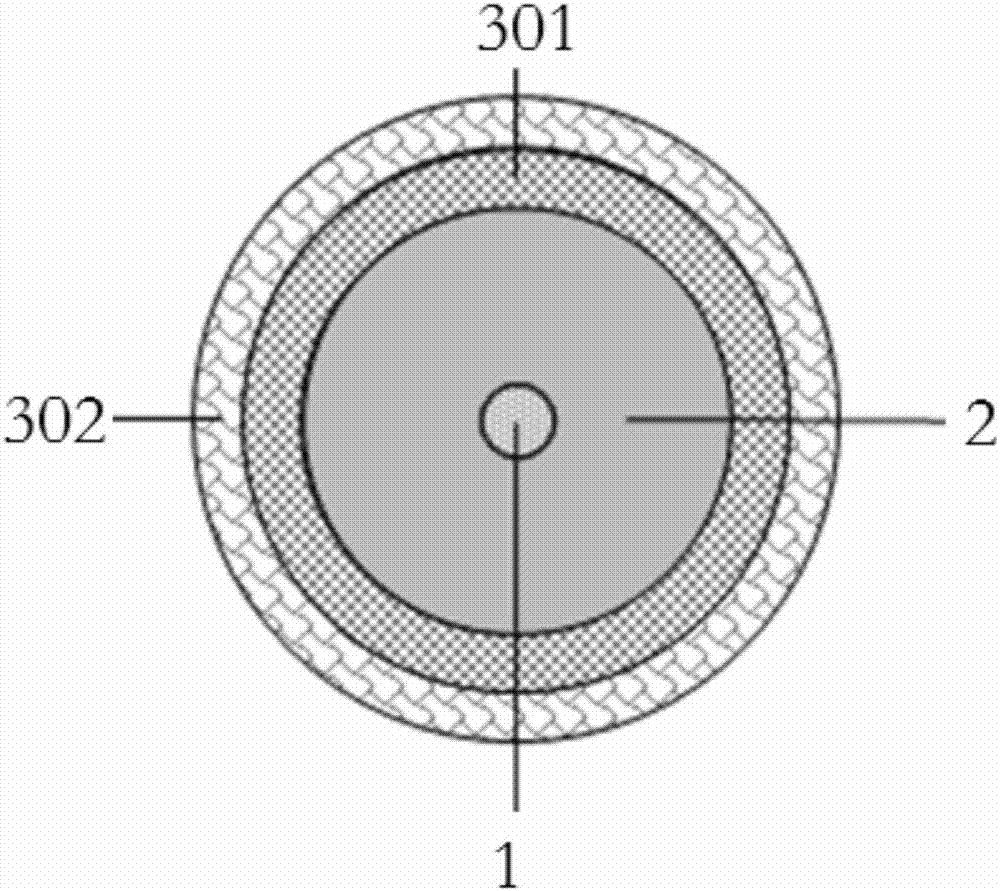

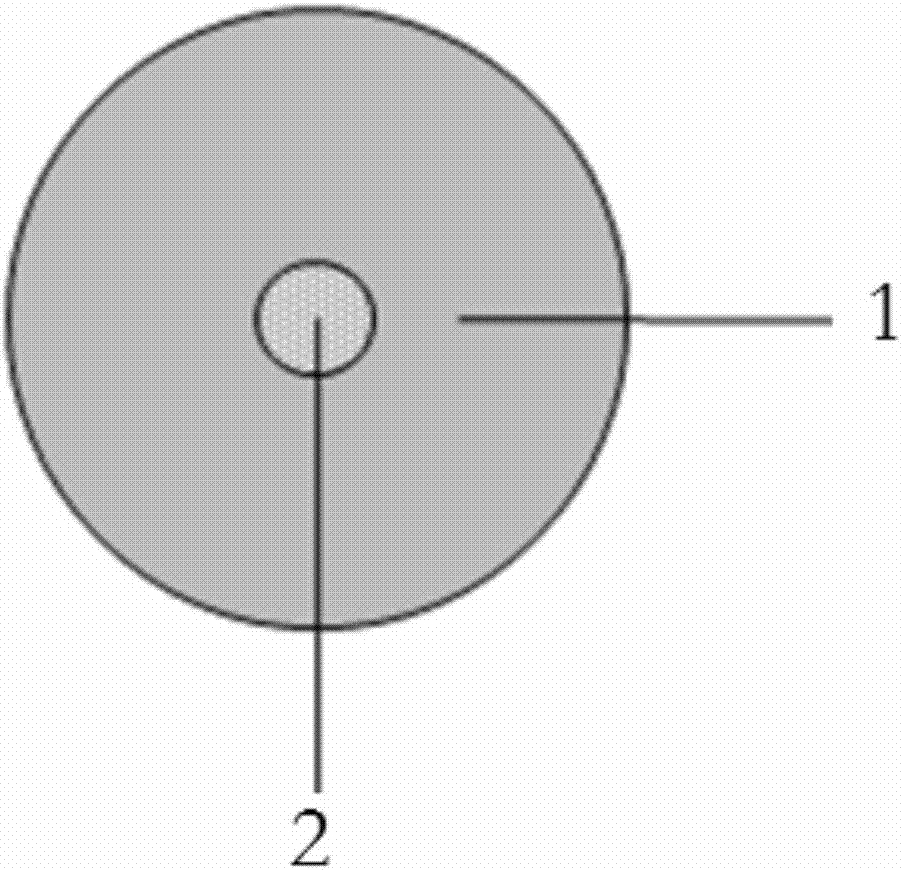

[0069] like figure 1 , figure 2 and image 3 As shown, an uplift pile with upper straight rod and lower screw rod suitable for seasonal frozen soil regions is characterized in that it includes: uplift steel bar 1 , mortar 2 and casing 3 .

[0070] The uplift pile includes a connected straight rod part and a screw part, the straight rod part is located above the uplift pile, and the screw part is located under the uplift pile.

[0071] The uplift-resistant steel bar 1 is located at the center of the uplift-resistant pile, and the uplift-resistant steel bar 1 is wrapped by mortar 2 to form a columnar structure. The pullout-resistant steel bars 1 can be replaced by steel strands.

[0072] The number of said pullout steel bars 1 is one.

[0073] The pullout steel bar 1 is provided with a ring support every 2-3m along the length direction.

[0074] A joint 101 beyond the top of the uplift pile is left on the top of the uplift steel bar 1, and the joint 101 is connected with t...

Embodiment 2

[0082] like Figure 4 , Figure 5 and Image 6 As shown, an uplift pile with upper straight rod and lower screw rod suitable for seasonal frozen soil regions is characterized in that it includes: a steel cage 1 , concrete 2 and casing 3 .

[0083] The uplift pile includes a connected straight rod part and a screw part, the straight rod part is located above the uplift pile, and the screw part is located under the uplift pile.

[0084] The reinforcement cage 1 is arranged along the axial length of the uplift pile, and the inside and outside of the reinforcement cage 1 are wrapped with concrete 2 to form a columnar structure.

[0085] All the longitudinal pull-out steel bars of the reinforcement cage 1 are equal in length.

[0086] A joint 101 beyond the top of the uplift pile is left on the top of the reinforcement cage 1, and the joint 101 is connected with the cap or the superstructure.

[0087] Threads are provided on the lower outer wall of the cylindrical structure to ...

Embodiment 3

[0094] like Figure 7 Shown, a kind of construction method of the upper straight rod lower screw rod uplift pile that is suitable for seasonal permafrost region is characterized in that, comprises the following steps:

[0095] 1) The drilling rig is in place, and the pull-out steel bars or steel cages are made.

[0096] The drill bits of the drilling rig are common straight rod drill bits and threaded rod drill bits, and the drill bits of the drilling rig can be extended as required.

[0097] 2) The straight section of the uplift pile is drilled into the hole.

[0098] The depth drilled into the ground by the straight rod drill bit is the length of the straight rod section of the uplift pile. The straight drill bit can be extended at the upper end as required.

[0099] 3) Lift the straight drill bit.

[0100] The straight-stem drill bit that has been drilled to a predetermined depth in the ground is lifted to the surface and removed.

[0101] 4) Install double-layer casin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com