Method for inverting carbon dioxide flooding frontal edge by multi-point continuous pressure measurement data

A carbon dioxide and data inversion technology, applied in the direction of electrical digital data processing, special data processing applications, measurement, etc., can solve the problems of development and management lag, inability to obtain continuous changes in carbon dioxide displacement fronts, serious gas channeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

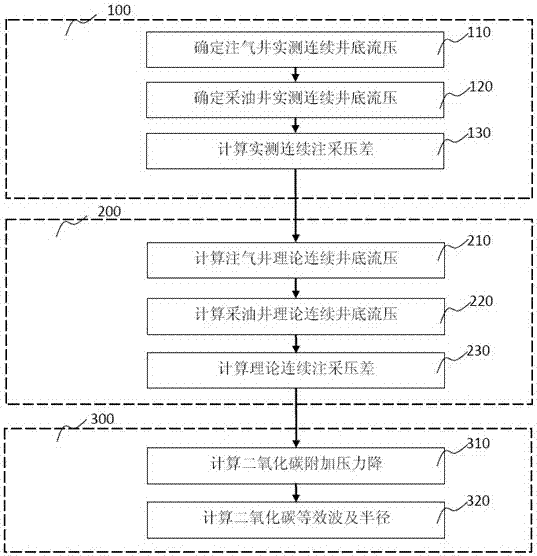

[0097] Such as figure 1 as shown, figure 1 It is a flow chart of the method for inverting the carbon dioxide flooding front by using multi-point continuous pressure measurement data of the present invention.

[0098] In step 100, the measured continuous injection-production pressure difference is calculated, and the specific steps include the step 110 of determining the measured continuous bottomhole flowing pressure of the gas injection well, the step 120 of determining the measured continuous bottomhole flowing pressure of the oil production well, and the step 130 of calculating the measured continuous injection-production pressure difference.

[0099] The measured continuous injection-production pressure difference Δp h (t) refers to the measured continuous bottomhole flowing pressure p of the gas injection well inj-h (t) and the measured continuous bottomhole flowing pressure p pro-h (t) difference, the definition formula is:

[0100] Δp h (t)=p inj-h (t)-p pro-h (t...

Embodiment 2

[0158] Example 2: Comparison of Calculation Results of Carbon Dioxide Equivalent Sweep Radius and Numerical Simulation Technology

[0159] The validity of the well testing method for pressure difference instability between injection and production wells was verified by using the composition theory model. The theoretical model of components is designed, the plane size of the geological model is 999m×999m, the grid dimension is 111×111×3=36963, and the grid size is 9m×9m×5m. The grid in the area of 180m×180m near the wellbore is densified, the dimension of the densified grid is 123×123×3=45387, and the size of the densified grid is 3m×3m×1m. The model is a five-point well pattern. There are channeling channels between production wells P1, P3, P2, and P4 and gas injection well P0, and the permeability is 25, 100×10 ‐3 μm 2 .

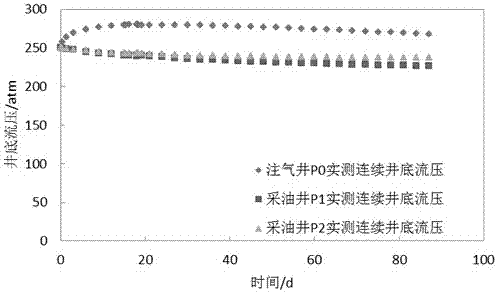

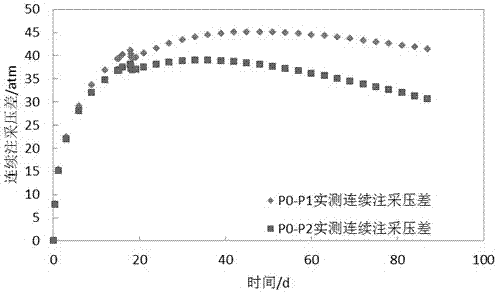

[0160] ①Calculation of measured continuous injection-production pressure difference

[0161] The measured bottomhole flowing pressure of gas injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com