Nonsymmetrical damping structure tensioning wheel bearing unit

A technology of damping structure and tensioner, which is applied in the field of auto parts, can solve the problems affecting the service life of products and belts, the wear of tensioner and belt, and the whistling of tensioner, so as to improve the service life and reduce vibration , Product performance and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

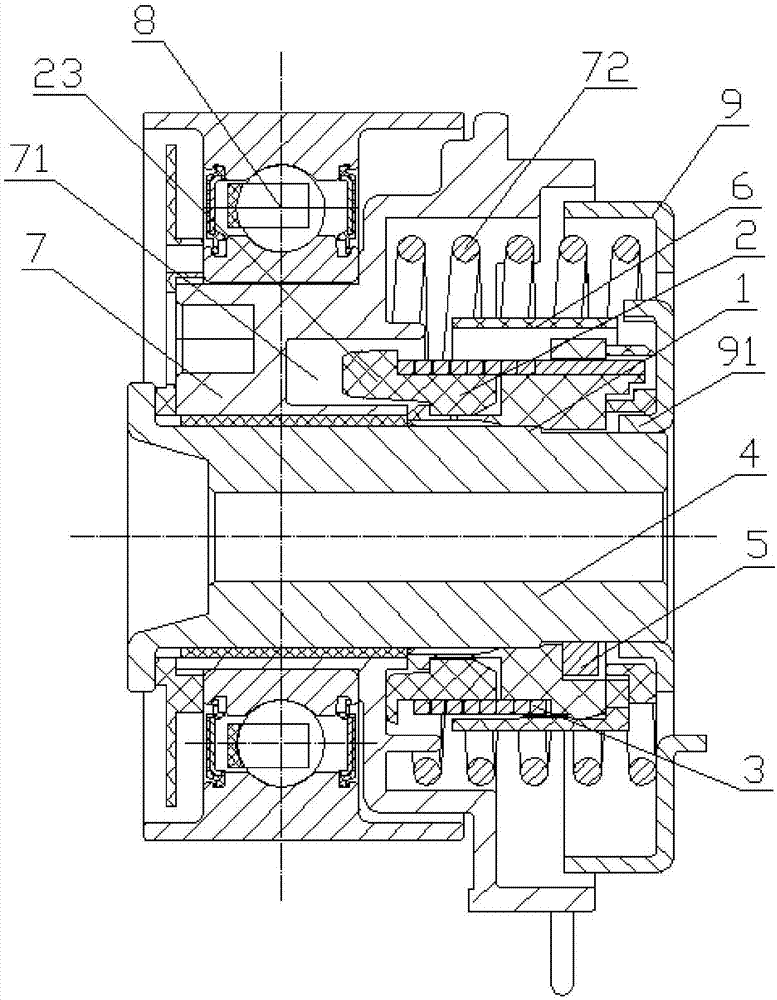

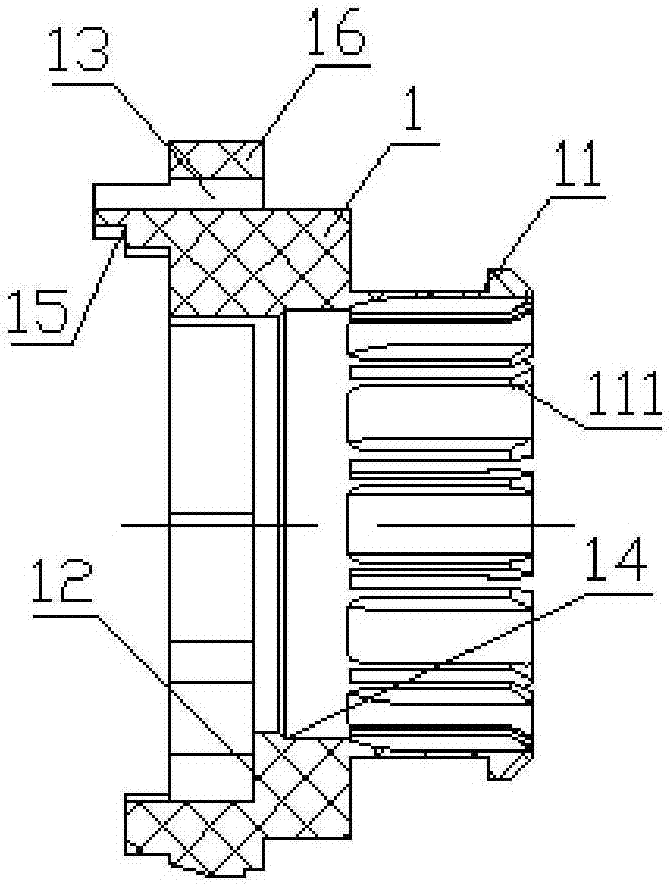

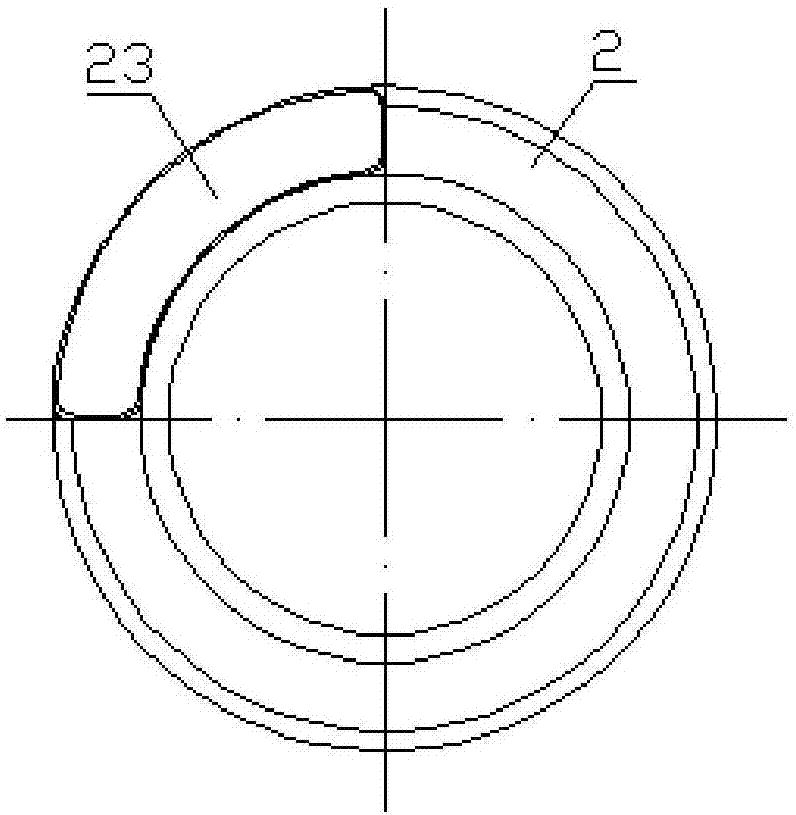

[0028] Such as Figure 1 to Figure 9 The illustrated tensioner bearing unit with an asymmetrical damping structure includes a mandrel 4 , a sleeve 7 mounted on the mandrel, a bearing 8 mounted on the sleeve 7 , and a tensioner spring 72 . At the same time, the present invention adds a set of spring damping mechanism inside the tensioning wheel, and the spring damping mechanism includes: the first spring seat 1, the second spring seat 2 and the rectangular spring 3, the first spring seat 1 and the second spring seat 2 and the rectangular spring The springs 3 are combined and installed on the mandrel 4, the rectangular spring 3 is fixed with the first spring seat 1, so that the first spring seat 1 and the rectangular spring 3 rotate together, and the rectangular spring 3 and the second spring seat 2 are Clearance fit ensures that the automatic tensioner can rotate freely when it is working. The axial first side of the sleeve is provided with a limiting groove 71 partially exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com