Method for detecting verticality of high tower based on three-dimensional laser scanning

A technology of three-dimensional laser and detection method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult control of precision, large data limitations, and difficult implementation of operations, and achieve fast speed, high precision, and point cloud acquisition easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

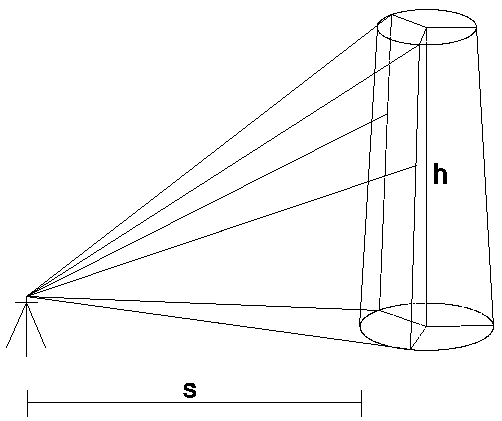

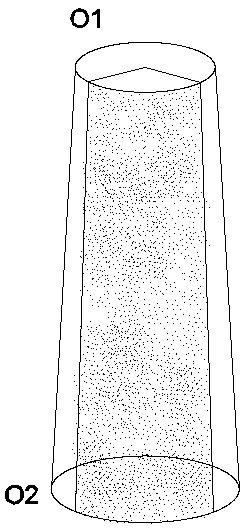

[0034] This embodiment provides a method for detecting the verticality of a towering tower based on three-dimensional laser scanning, combining figure 1 and figure 2 shown, including the following steps:

[0035] Step 1) Obtain point cloud data: set up a 3D laser scanner to obtain the point cloud data of the 1 / 3 ring section of the vertical projection of the tower;

[0036] Step 2) Build a TIN model: preprocess the point cloud data obtained in step 1) to build a TIN model of the 1 / 3 ring of the tower;

[0037] Step 3) Extract tower section: select two tower horizontal sections from the TIN model obtained in step 2);

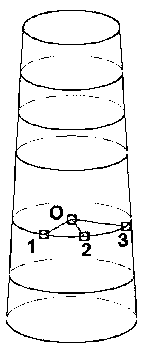

[0038] Step 4) Reduction of the center coordinates of the tower tube section: select any 3 points that are not collinear on the two tower tube horizontal contour sections in step 3), and determine the 3 points on each tower tube horizontal contour section A unique circular plane is used to calculate the center coordinates of the horizontal contour sections of...

Embodiment 2

[0042] On the basis of Example 1, specifically, the step 1) meets the following requirements:

[0043] a) The horizontal distance between the erection point of the 3D laser scanner and the tower is not less than 3 / 2 of the height of the tower, and it should be able to completely scan the height of the tower;

[0044] b) Use the compass to determine the first erection orientation, and the initial orientation of the subsequent repeated erection of the scanner should be consistent with the initial orientation;

[0045] c) Every time the scanner is fixed and erected, a centering and leveling device must be used to ensure the scanner is level;

[0046] d) Each scan first performs a fast panoramic rough scan, and then performs a fine scan of the target tower.

Embodiment 3

[0048] In the above two embodiments, the horizontal contour sections of the two towers selected in step 3) should be the upper and lower sections of the tower whose verticality is to be measured. Select the horizontal contour section according to the tower section to be measured, which should be the upper and lower sections of the tower section to be measured.

[0049] If the tower section to be measured is the entire tower, then the two tower horizontal contour sections selected in step 3) are the top section and bottom section of the tower, and the data in the top section and bottom section Calculate the verticality of the entire tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com