An open, arrayed, integrated electrochemical gas sensor and its manufacturing method

A gas sensor and manufacturing method technology, applied in the direction of material electrochemical variables, can solve the problems of poor selectivity, low sensitivity of electrochemical gas sensors, difficulty in forming arrays and integration, etc., to achieve improved repeatability and easy integrated design Make, increase the effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

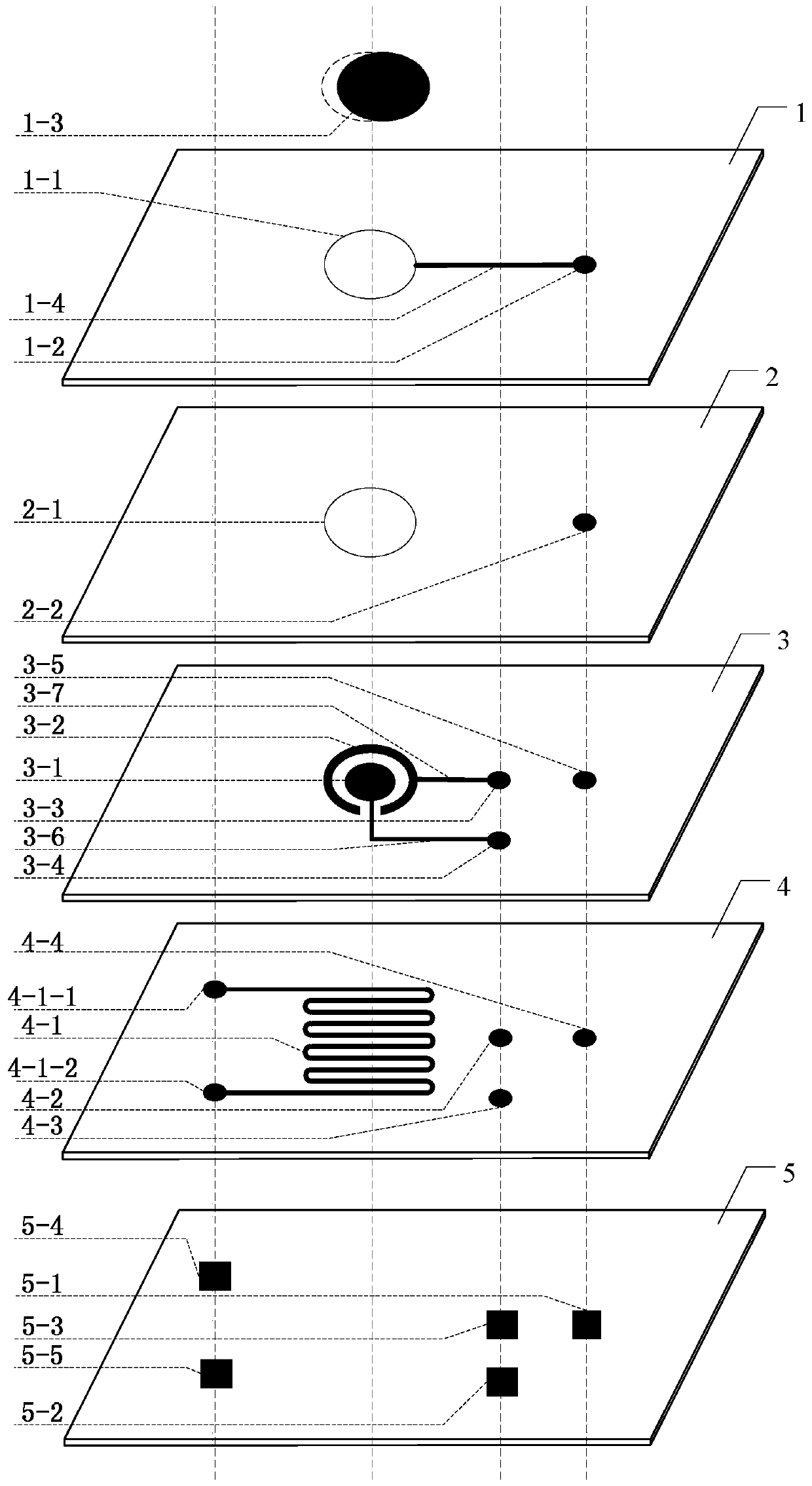

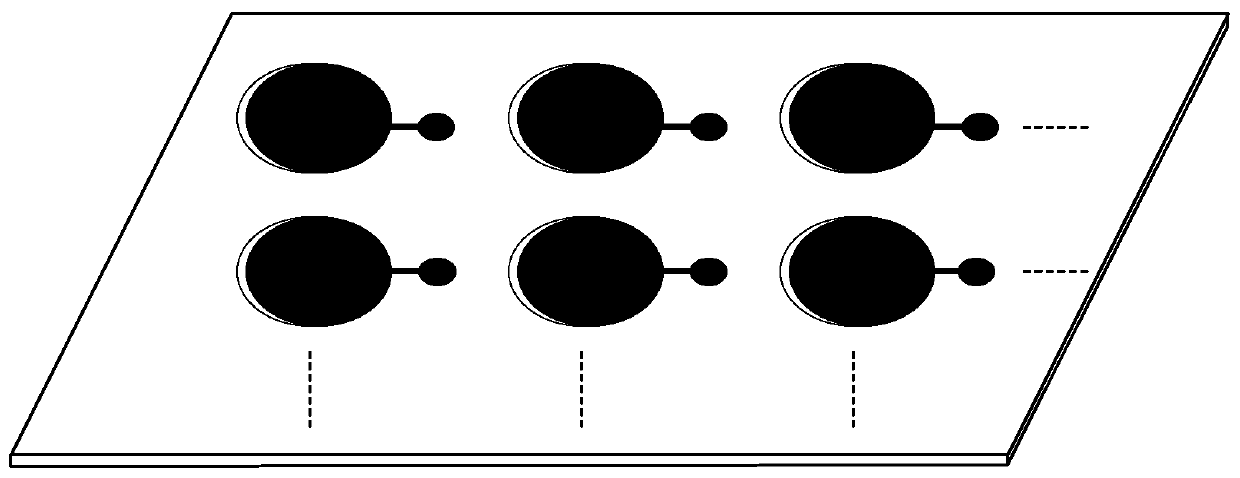

[0044] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment in detail. An open, arrayed, and integrated electrochemical gas sensor described in this embodiment includes a plurality of sensing units arranged in an array and integrated into one body. The sensing unit includes an upper electrode layer 1, an electrolytic cell layer 2, a lower electrode layer 3 and an extraction layer 5;

[0045] The upper electrode layer 1, the electrolytic cell layer 2, the lower electrode layer 3 and the lead-out layer 5 are sequentially laminated;

[0046]The substrate of the upper electrode layer 1 is provided with a first electrolytic cell through hole 1-1, a first lead 1-4, a first via hole 1-2 and a catalytic electrode 1-3; the catalytic electrode 1-3 passes through the first lead 1 -4 communicates with the first through hole 1-2, and the catalytic electrode 1-3 semi-closed covers the through hole 1-1 of the first electrolytic cell;

[0047] The subst...

specific Embodiment approach 2

[0059] Specific embodiment 2: This embodiment is a further description of an open, arrayed, and integrated electrochemical gas sensor described in Specific Embodiment 1. In this embodiment, the slurry of catalytic electrodes 1-3 Includes porogen.

[0060] Catalytic electrodes 1-3 are printed and molded using catalytic electrode paste, and the porous catalytic electrode is realized by adding a pore-forming agent in the paste to increase the sensitivity to sensing gas. The pore-forming agent is carbon powder, organic matter, etc.; the catalytic electrode paste is noble metal and compound, etc.

specific Embodiment approach 3

[0061] Specific embodiment three: this embodiment is a kind of open, arrayed, integrated electrochemical gas sensor described in specific embodiment two, and in this embodiment, the substrate of the lower electrode layer 3 is also provided with There are a reference electrode 3-2, a third lead wire 3-7 and a fifth via hole 3-3; the reference electrode 3-2 is a semi-closed ring, the counter electrode 3-1 is located in the semi-closed ring, and the reference electrode 3-2 communicates with the fifth via hole 3-3 through the third lead 3-7;

[0062] A third lead-out terminal 5-3 is also provided on the substrate of the lead-out layer 5;

[0063] The third lead-out end 5-3 communicates with the fifth via hole 3-3.

[0064] The counter electrode 3-1 and the reference electrode 3-2 are coaxially arranged, the counter electrode 3-1 is located inside the reference electrode 3-2, the reference electrode 3-2 presents a semi-closed ring structure, and the gap is used for the counter ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com