A commodity carrying out device of a vending machine

A technology for vending machines, merchandise, applied in the direction of coinless or similar appliances, coin-operated devices for dispensing discrete items, coin-operated devices for dispensing discrete items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

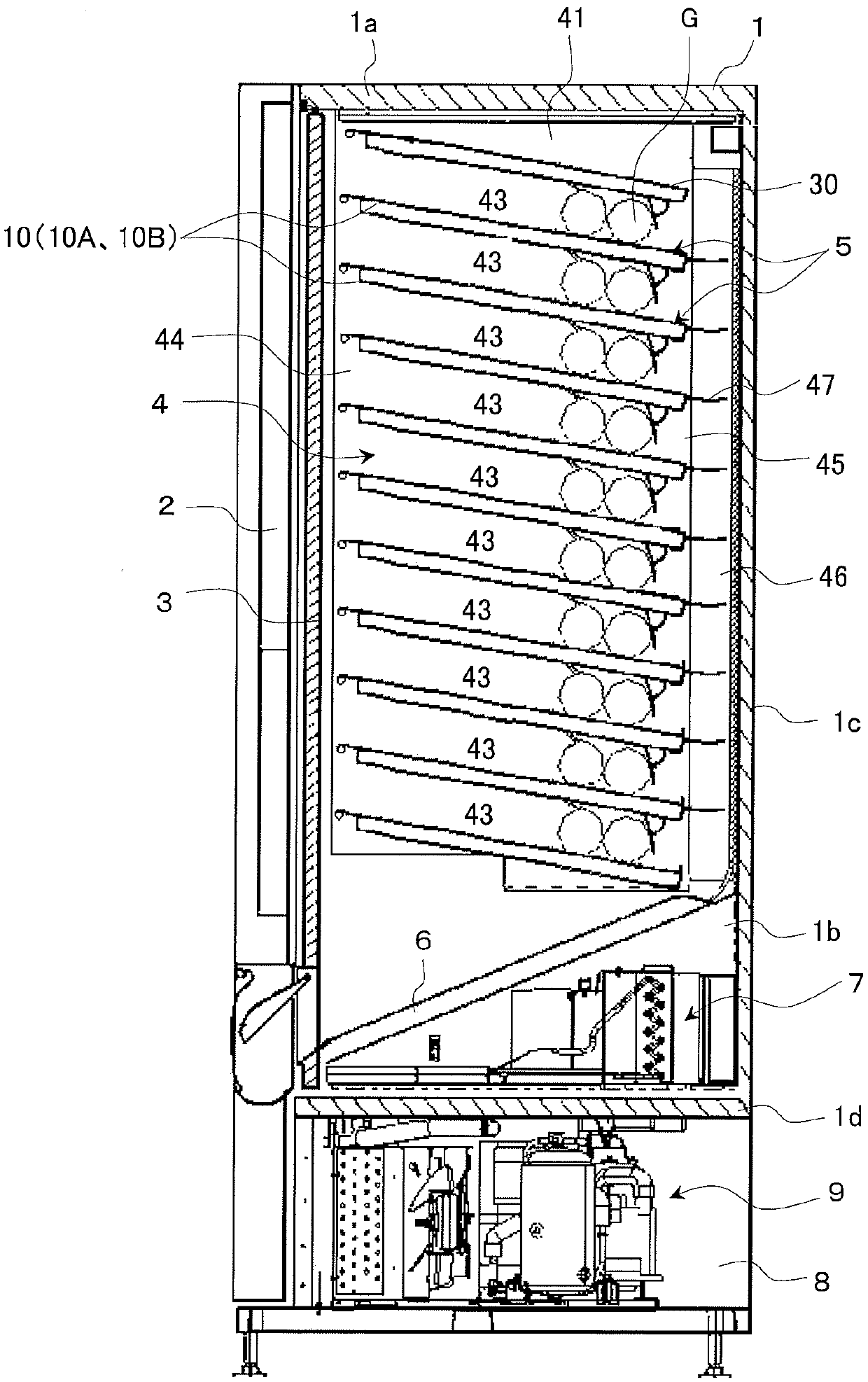

[0129] Figure 1 to Figure 2 2 is the product delivery device of the automatic vending machine according to Embodiment 1 of the present invention.

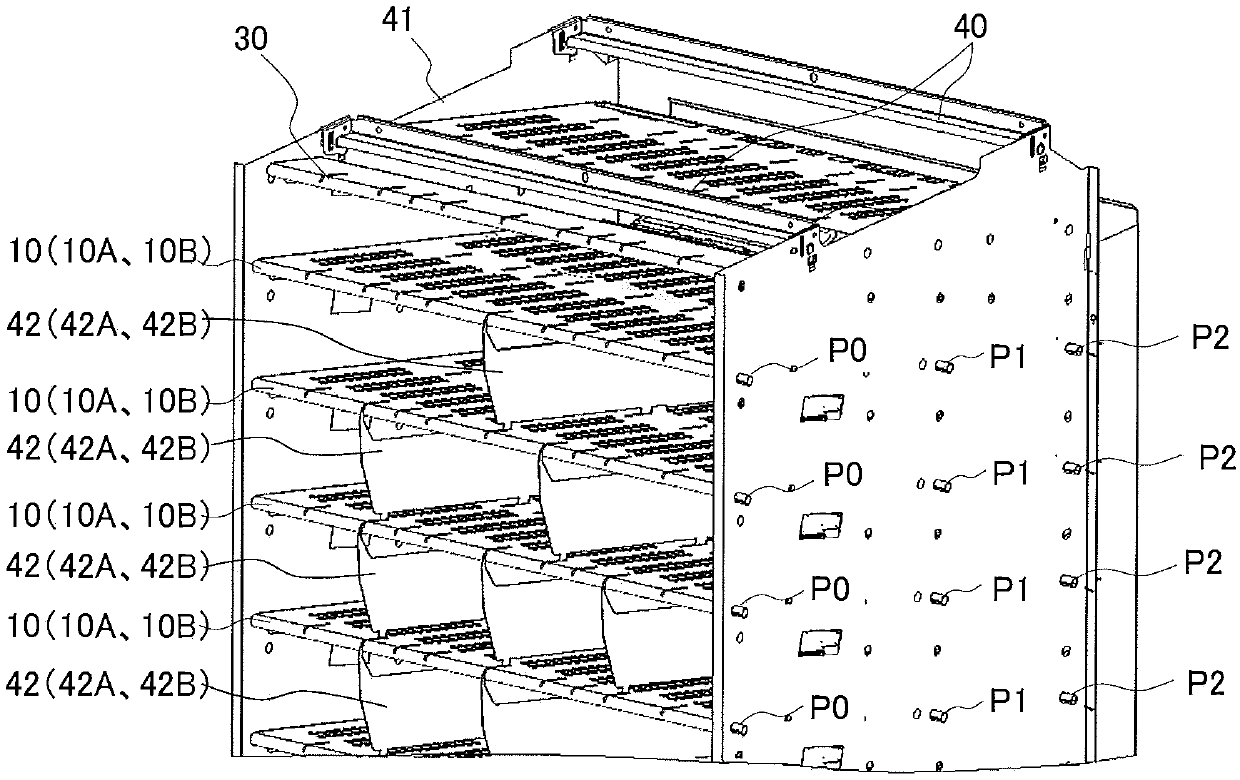

[0130] figure 1 It is a schematic side view of a vending machine that sells canned beverages and PET bottled beverages as an example of the automatic vending machine that is the object of the present invention, figure 2 It is viewed from the upper right obliquely figure 1The product storage shelf of , an exploded perspective view showing the main parts of the top product storage shelf. In addition, "left and right" means left and right when viewed from the front of the automatic vending machine.

[0131] Such as figure 1 As shown, this automatic vending machine includes: a main body cabinet 1 formed as a heat-insulating box with an open front, and an outer door 2 supported on the front of the main body cabinet 1 in an openable and closable manner. The front of the product storage compartment of the main body cabinet 1 is ...

Embodiment approach 2

[0200] figure 1 , figure 2 , Figure 11 , Figure 12 , Figure 18 , Figure 20 and Figure 23 ~ Figure 3 Numeral 6 denotes a product delivery device of the automatic vending machine according to Embodiment 2 of the present invention.

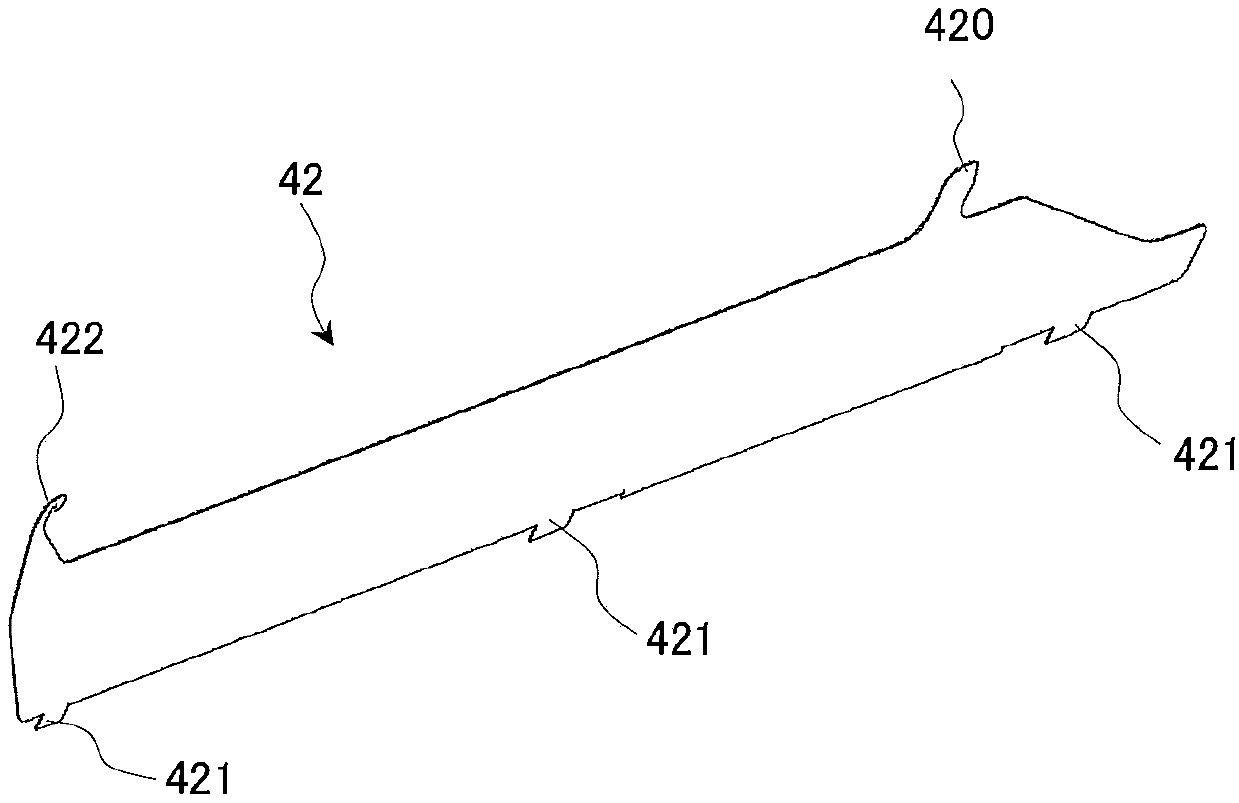

[0201] Merchandise storage shelf 10A, such as Figure 23 As shown, flanges 11, 11 bent downward from the left and right side edges of the rectangular plate surface are formed for reinforcement. At the front end of the commodity storage shelf 10, a hollow portion 12 bent into a hollow cylindrical shape (curled shape) is formed. The front portion of the flanges 11, 11 is notched to form a pin insertion portion 11a, and the flange 11 is substantially in the middle and at the rear end to form arc-shaped pin engaging portions 11b, 11c by notching. The pin insertion portions 11a and the pin engagement portions 11b, 11c provided on the flanges 11, 11 and the pin members P0 to P2 (refer to figure 2 ) to face each other, the product storage she...

Embodiment approach 3

[0282] figure 1 , figure 2 , Figure 18 and Figure 37 ~ Figure 59 It is a product dispensing device for an automatic vending machine according to Embodiment 3 of the present invention.

[0283] Commodity storage shelf 10B, such as Figure 37 As shown, flanges 11, 11 bent downward from the left and right side edges of the rectangular plate surface are formed for reinforcement. A hollow portion 12 bent into a hollow cylindrical shape (curled shape) is formed at the front end of the product storage shelf 10B. The front portion of the flanges 11, 11 is notched to form a pin insertion portion 11a, and the flange 11 is substantially in the middle and at the rear end to form arc-shaped pin engaging portions 11b, 11c by notching. The pin insertion portions 11a and the pin engagement portions 11b, 11c provided on the flanges 11, 11 and the pin members P0 to P2 (refer to figure 2 ) to face each other, the product storage shelf 10 is arranged so that the product storage shelf 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com