A mechanical extrusion molding device for thimble heat transfer tubes

A technology of extrusion molding and heat transfer tubes, which is applied in the direction of heat exchange equipment, etc., can solve the problems that the synchronization of the hydraulic system is difficult to ensure, the hydraulic oil is easy to leak and pollute the environment, and there are few extrusion molding devices for the heat transfer tubes of the cells. Achieve the effects of maintaining synchronization, improving processing and manufacturing speed, and ensuring work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

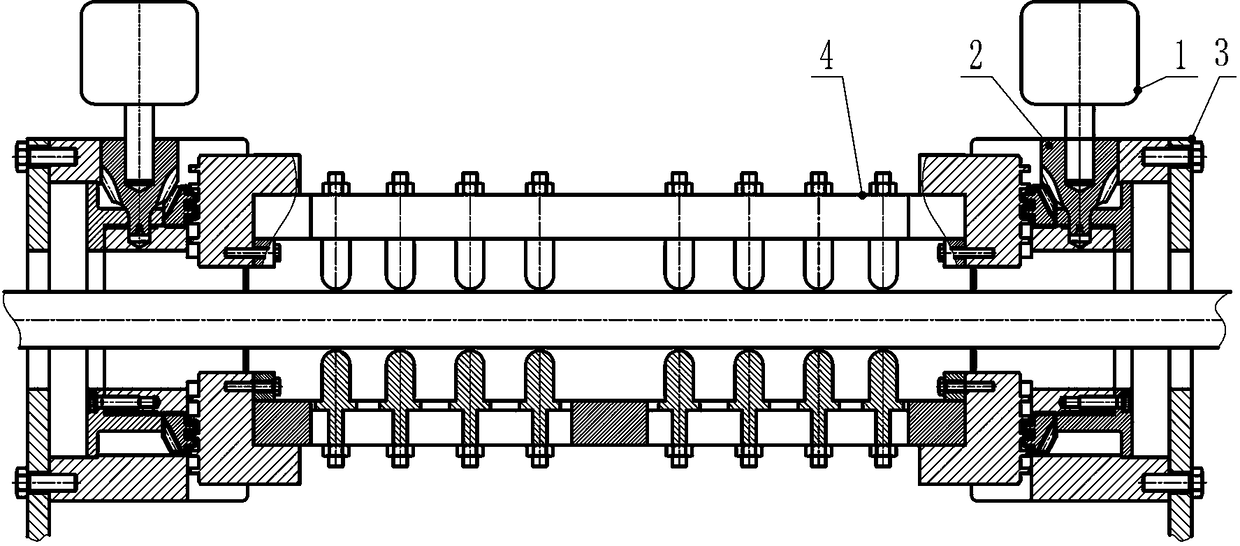

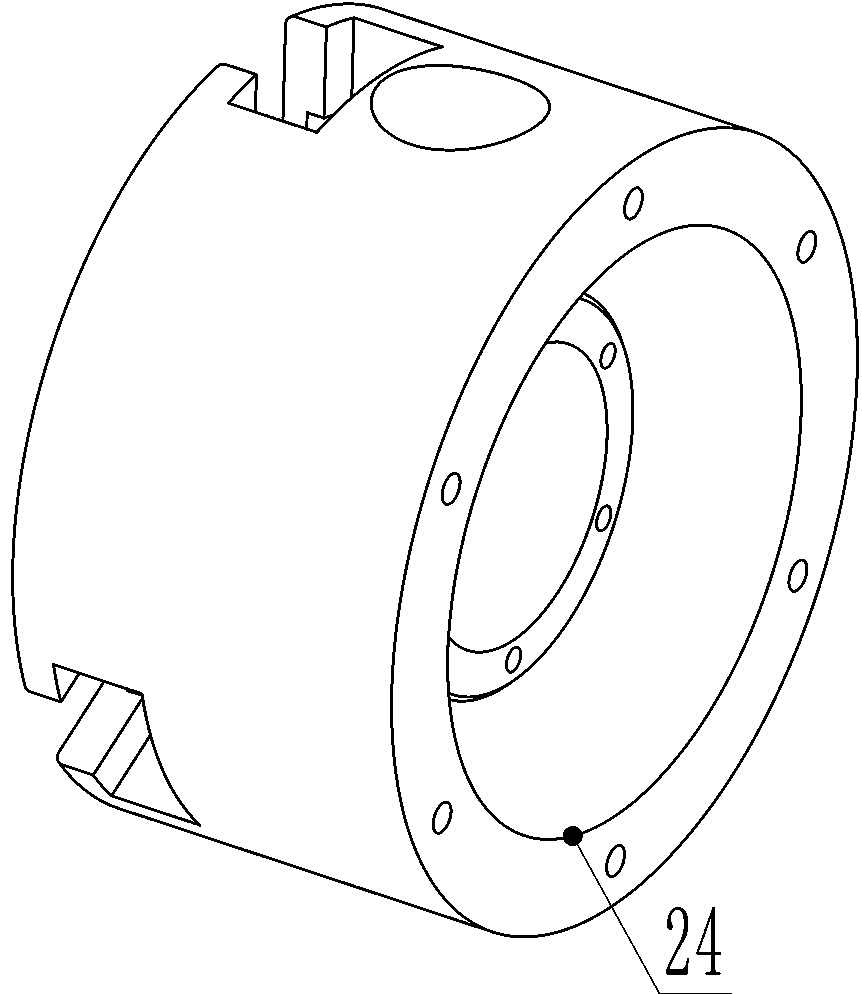

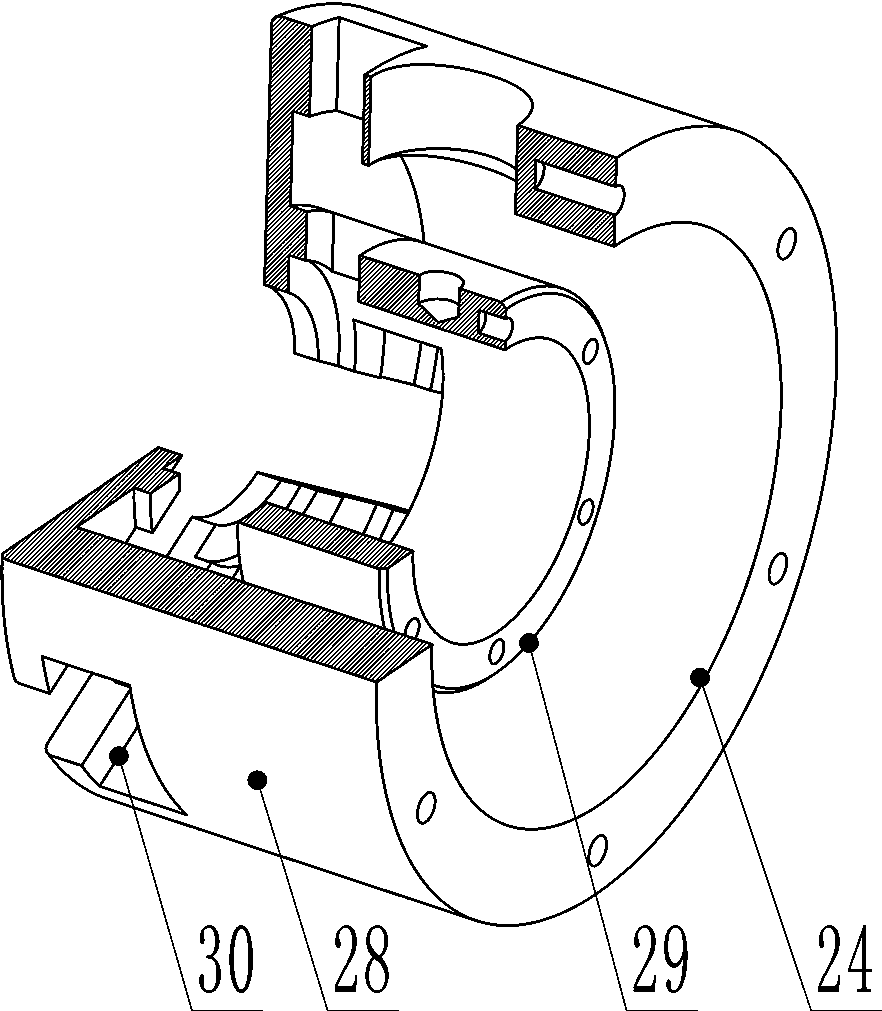

[0031] refer to figure 1 , a mechanical extrusion molding device for small cell heat transfer tubes, consisting of a motor drive system 1, a transmission system 2, a frame system 3, and a punch system 4. The small bevel gear 21 at the upper end of the transmission system 2 is connected with the motor drive system 1, the cover plate 25 bolts at the right end of the transmission system 2 are connected with the frame system 3, and the claws 23 bolts at the left end of the transmission system 2 are connected with the punch system 4. The working principle is: the motor drive system 1 provides driving force for the extrusion molding device; the motor drive system 1 drives the small bevel gear 21 to rotate, and the small bevel gear 21 meshes with the large bevel gear 22 to make the large bevel gear 22 rotate; the large bevel gear 22 The planar thread 27 designed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com